Making method of anti-oxidative sausage

A production method and anti-oxidation technology, applied in food preparation, application, food science, etc., can solve problems such as unfavorable health, threat to human health, single type, etc., to improve product sensory quality and flavor characteristics, enhance functionality, The effect of improving health performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Raw materials: Cut fresh pork into pieces, wash in 4°C water, remove blood clots and pigskin, weigh them according to the ratio of fat to lean 1:4, grind them, and chop ginger for later use.

[0034] (2) Ingredients: Weigh 100 parts of fat and lean meat, 7.5 parts of white sugar, 3 parts of salt, 0.2 part of monosodium glutamate, 0.1 part of five-spice powder, 0.15 part of ginger, 2 parts of Daqu, 10 parts of purified water, 3 parts of white sesame powder, after Crush and pass through a 100-mesh sieve.

[0035] (3) Rapid dehydration: Put the stuffed sausages into a constant temperature incubator for two days of rapid dehydration. In the first stage, the temperature of the incubator is 50°C and placed for 24 hours. In the second stage, the temperature is adjusted to 30°C and placed for 24 hours.

[0036] (4) Natural air-drying: take out the above-mentioned sausages after rapid dehydration, and hang them naturally in a cool and ventilated place.

[0037] (5) Maturity...

Embodiment 2

[0045] (1) raw material: with embodiment 1.

[0046] (2) Ingredients: Weigh 100 parts of fat and lean meat, 6 parts of sugar, 4 parts of salt, 0.1 part of monosodium glutamate, 0.2 part of five-spice powder, 0.1 part of ginger, 3 parts of Daqu, 5 parts of purified water, 4 parts of white sesame powder, after Crush and pass through a 100-mesh sieve.

[0047] (3) Rapid dehydration: Put the stuffed sausages into a constant temperature incubator for two days of rapid dehydration. The temperature of the incubator is 55°C for 24 hours in the first stage, and the temperature is adjusted to 35°C for 24 hours in the second stage.

[0048] (4) Naturally air-dried: with embodiment 1.

[0049] (5) maturity: with embodiment 1.

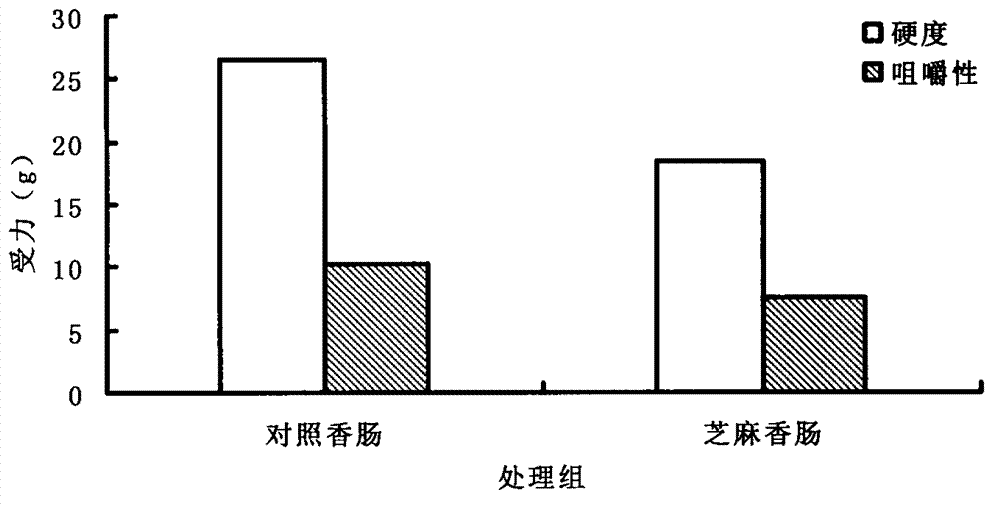

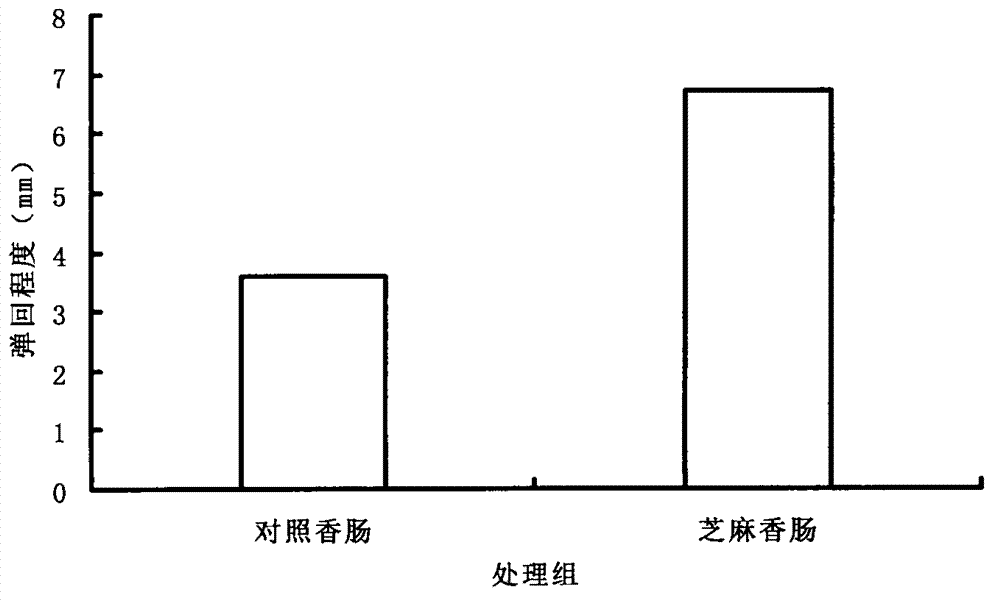

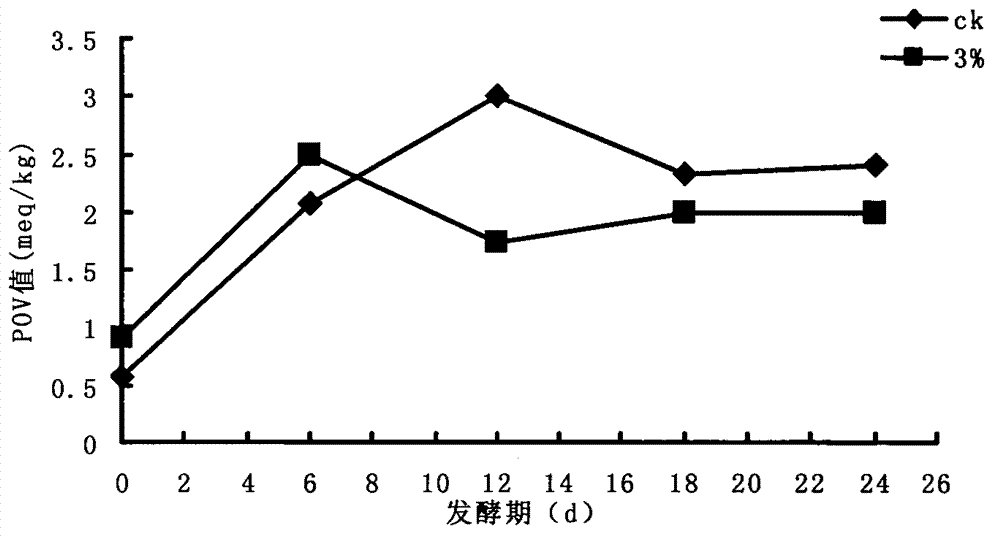

[0050] The product that the inventive method makes and the traditional product of control group are carried out flavor component analysis, and result is as follows:

[0051] There were no ketones in the volatile compounds of the control group, while the content of...

Embodiment 3

[0055] (1) raw material: with embodiment 1.

[0056] (2) Ingredients: Weigh 100 parts of fat and lean meat, 9 parts of sugar, 2 parts of salt, 0.3 parts of monosodium glutamate, 0.15 parts of five-spice powder, 0.2 parts of ginger, 1 part of Daqu, 15 parts of purified water, 2 parts of white sesame powder, after Crush and pass through a 100-mesh sieve.

[0057] (3) Rapid dehydration: Put the stuffed sausages into a constant temperature incubator for two days of rapid dehydration. The temperature of the incubator is 45°C for 24 hours in the first stage, and the temperature is adjusted to 25°C for 24 hours in the second stage.

[0058] (4) Naturally air-dried: with embodiment 1.

[0059] (5) maturity: with embodiment 1.

[0060] The product that the inventive method makes and the traditional product of control group are carried out flavor component analysis, and result is as follows:

[0061] There were no ketones in the volatile compounds of the control group, while the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com