A high-pressure atomization combined with countercurrent alcohol precipitation device and method

A high-pressure atomization, countercurrent technology, applied in chemical instruments and methods, feeding/discharging devices of sedimentation tanks, separation methods, etc., can solve the problems of discontinuity in the whole process, low product recovery rate, unstable quality, etc. Achieve the effect of sufficient alcohol precipitation, high product recovery rate, uniform and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

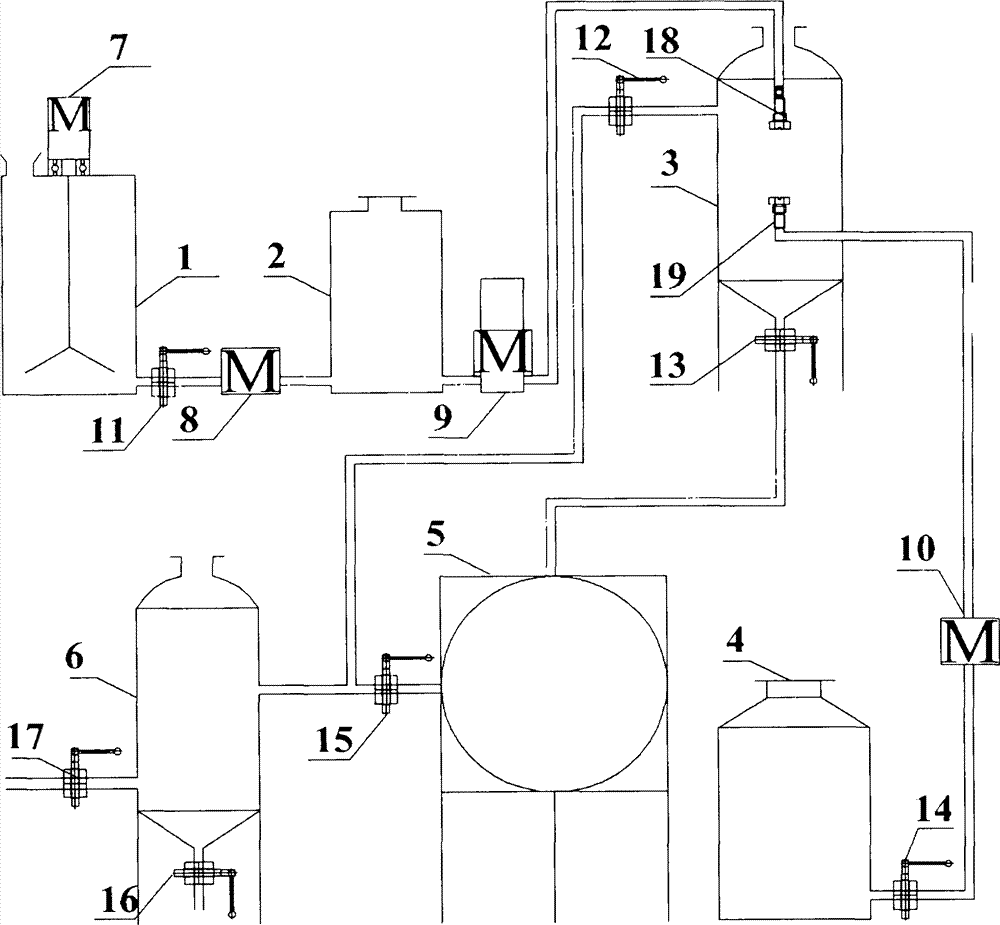

[0021] The present embodiment is illustrated by taking the water-extracted extract of Salvia miltiorrhiza as an example, and includes the following steps:

[0022] Step 1, add ethanol in advance: add the ethanol of 3 / 4 tank volume in alcohol precipitation tank 3;

[0023] Step 2, stirring: 600L of Salvia miltiorrhiza water extract with a specific gravity of 1.18 is added to the stirring tank 1, and the stirring device 7 on the stirring tank 1 is opened, and after stirring for 30 minutes, the stirring rate is 80r / min; Open the valve 11 and the material and liquid transportation The pump 8 sends the material liquid into the transfer tank 2;

[0024] Step 3, high pressure atomization combined with countercurrent alcohol precipitation: turn on the plunger pump 9, adjust the plunger pump pressure to 2.5Mpa, the flow rate 300L / h, pass through the high pressure pipeline and the first nozzle 18 in turn, spray the Salvia miltiorrhiza extract into a misty liquid Drop into the alcohol p...

Embodiment 2

[0028] Basically the same as Example 1, the difference is: in step 2, the specific gravity of Salvia miltiorrhiza extract is 1.20, and the stirring time is 25min, and in step 3, the pressure of the plunger pump is 3.5Mpa, and the flow rate is 350L / h. Add 85% ethanol in countercurrent to the flow rate.

[0029] After the clear liquid was concentrated under reduced pressure, 415L of alcohol immersion cream was obtained, 152kg was precipitated, and the total phenolic acid recovery rate of Salvia miltiorrhiza was 91%.

Embodiment 3

[0031] Basically the same as Example 1, the difference is: in step 2, the specific gravity of Salvia miltiorrhiza extract is 1.15, stirring for 20min, in step 3, the pressure of the plunger pump is 4Mpa, and the flow rate is 400L / h, and after 8 minutes of spraying, add in countercurrent with 2400L / h 85% ethanol.

[0032] After the clear liquid was concentrated under reduced pressure, 430L of alcohol immersion ointment was obtained, with a precipitation of 142kg, and the recovery rate of total phenolic acids of Salvia miltiorrhiza was 92.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com