Ganmaoling granules and ethanol precipitation technology thereof

An alcohol precipitation process and Ganmaoling technology are applied in the fields of plant raw materials, respiratory diseases, organic active ingredients, etc., which can solve the problems of insufficient alcohol precipitation, inability to mix the medicinal liquid evenly, and long alcohol precipitation time, so as to shorten the alcohol precipitation. time, to meet large-scale industrial production, the effect of short extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

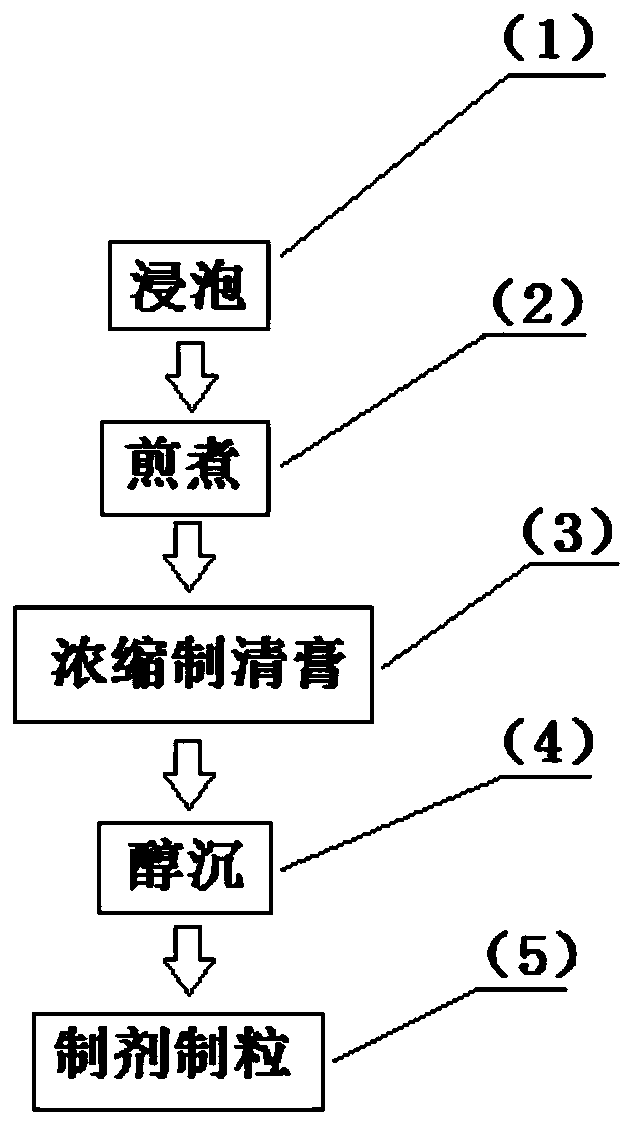

[0024] The preparation technology of Ganmaoling Granule Clear Cream of the present embodiment comprises the following steps:

[0025] Step A: One decoction

[0026] Put the selected Sanchaku, Marigold Silver Plate, Wild Chrysanthemum, and Gangmei into the extraction tank in sequence according to the formula amount, add 8 times the amount (w / w) of water, soak for 45 minutes, and then decoct once. When the temperature reaches 100°C, quickly close the steam valve, then open the steam valve of the jacket of the extraction tank, and heat the medicinal liquid in the extraction tank through the jacket, so that the medicinal liquid in the extraction tank is in a slightly boiling state, and decoct for 2 hours to obtain a decoction. Open the liquid outlet valve of the extraction tank to extract the medicinal liquid, make the primary decoction enter the liquid storage tank, and then close the liquid outlet valve of the extraction tank.

[0027] Step B: Second decoction

[0028] Contin...

Embodiment 2

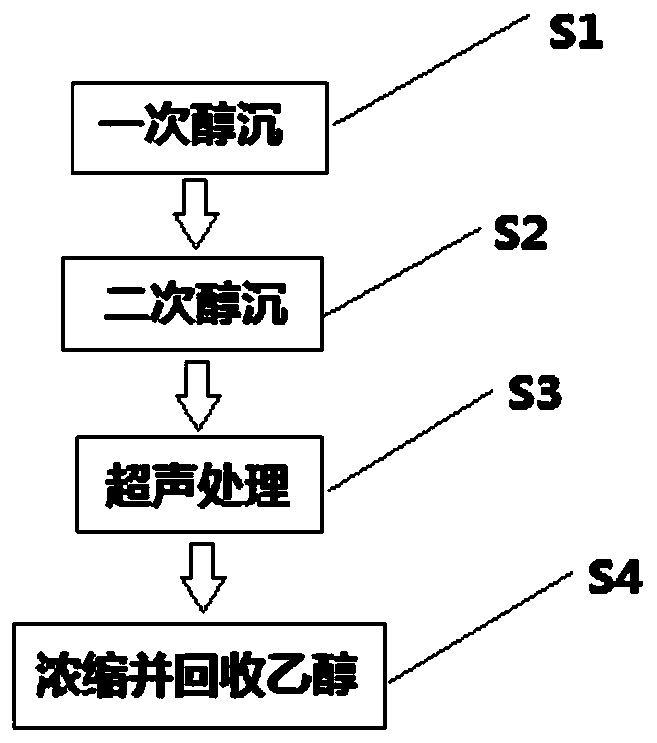

[0037] The preparation process of Ganmaoling granule clear ointment in this example is exactly the same as that in Example 1, and will not be repeated here. The difference between the present embodiment Ganmaoling granule alcohol precipitation process and embodiment 1 is as follows:

[0038] Step S1: Alcohol precipitation once, transport the concentrated clear ointment with a relative density of 1.1 to the alcohol precipitation tank through the pipeline, confirm the volume of the clear ointment through the sight glass and the scale mark, add 50% ethanol, and it is mixed with the clear ointment The volume ratio is 1.5:1, stir while adding, and stir for 10 to 30 minutes;

[0039] Step S2: second alcohol precipitation, continue to add 95% ethanol, and stir while adding, when the alcohol content of the clear paste is 65%, continue to stir for 10 to 30 minutes;

[0040] Step S3: ultrasonic treatment, the stirred paste was ultrasonically treated for 45 minutes, then cooled and left s...

Embodiment 3

[0042] The preparation process of Ganmaoling granule clear ointment in this example is exactly the same as that in Example 1, and will not be repeated here. The difference between the present embodiment Ganmaoling granule alcohol precipitation process and embodiment 1 is as follows:

[0043] Step S1: Alcohol precipitation once, transport the concentrated clear ointment with a relative density of 1.1 to the alcohol precipitation tank through the pipeline, confirm the volume of the clear ointment through the sight glass and the scale mark, add 60% ethanol, and mix it with the clear ointment The volume ratio is 1:1, stir while adding, and stir for 10 to 30 minutes;

[0044] Step S2: secondary alcohol precipitation, continue to add 95% ethanol, and stir while adding, when the alcohol content of the clear paste is 85%, continue to stir for 10 to 30 minutes;

[0045] Step S3: ultrasonic treatment, the stirred paste was ultrasonically treated for 45 minutes, then cooled and left sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com