Laser transmission composite connecting method

A technology of laser transmission and composite connection, which is applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as weld damage, achieve local connection firmness, reliable connection strength, and improve the effect of connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

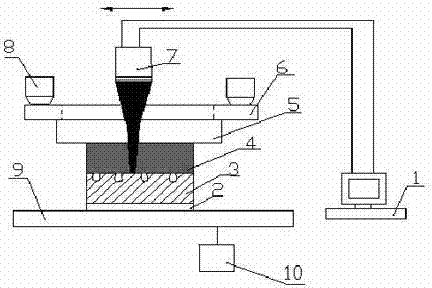

[0017] Below in conjunction with specific embodiment the present invention is further described, weld transparent nylon and 304 stainless steel metals with the present invention.

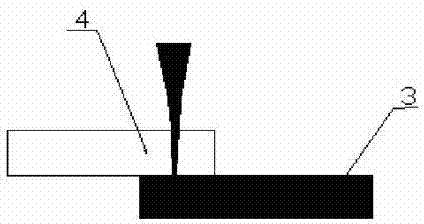

[0018] Welding preparation: The selected welding transparent light-transmitting material nylon 12 has a size of 10x10x2mm, and the light-absorbing material 304 stainless steel 14 has a size of 10x10x0.6mm. The laser transmission welding laser uses a continuous energy semiconductor laser generator 7 with a maximum power of 130w and a wavelength of 980nm±10nm.

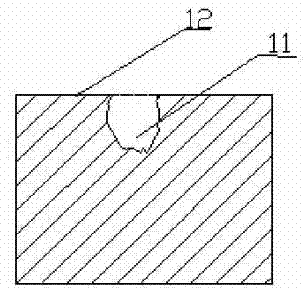

[0019] Surface treatment of the weldment: The sample 304 stainless steel 15 is ultrasonically cleaned with ethanol to remove surface impurities, placed on the workbench of the electric discharge machine tool, and processed with a copper tungsten electrode with a standard electrode diameter of 250um. According to the welding area position of the actual material, clean the impurities on the surface of nylon 13 with ethanol at the same time, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com