Bismercapto compound modified water-soluble quantum dot and its preparation method

A bis-mercapto compound and quantum dot technology, which is applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of poor stability of quantum dots, and achieve the effects of wide application range, easy realization, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In parts by weight, the formula is as follows:

[0023] Monomethyl ether-capped polyethylene glycol (mPEG, molecular weight 1000) 20 parts

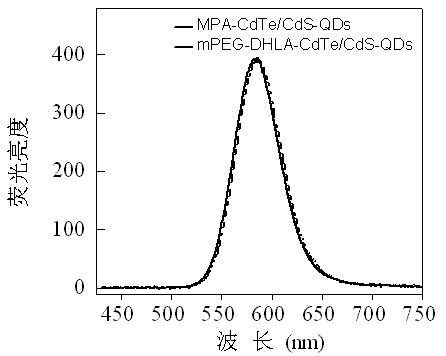

[0024] CdTe / CdS quantum dot solution (wavelength 580 nm, surface ligand is mercaptopropionic acid MPA) 150 parts

[0025] Preparation Process:

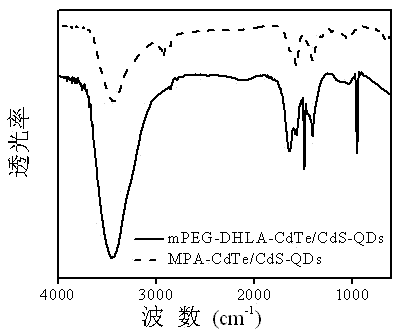

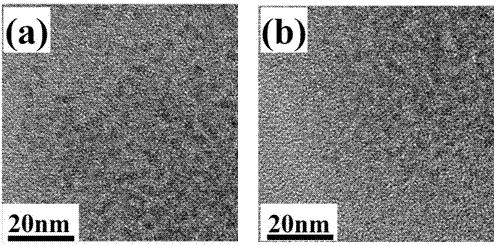

[0026] In parts by weight, 6 parts of lipoic acid (TA), 20 parts of monomethyl ether-capped polyethylene glycol (mPEG), and 1 part of p-dimethylaminopyridine (DMAP) were dissolved in 100 parts of dichloromethane. Then the mixed solution was reduced to 0 o C. Add 7 parts of N,N′-dicyclohexylcarbodiimide (DCC), keep warm for 1 hour, and react overnight at room temperature. After the reaction is over, first filter the reaction solution to remove insoluble matter, then evaporate the solvent by rotary evaporation, and add saturated NaHCO to the solid residue 3 50 parts of the solution, and then extracted three times with ethyl acetate. The ethyl acetate extracts were collected and drie...

Embodiment 2

[0037] In parts by weight, the formula is as follows:

[0038] Polyethylene glycol (PEG, molecular weight 3000) 60 parts

[0039] CdTe quantum dot solution (wavelength 545 nm, original surface ligand is thioglycolic acid TGA) 300 parts

[0040] Preparation Process:

[0041] In parts by weight, 6 parts of lipoic acid (TA), 60 parts of polyethylene glycol (PEG), and 1 part of p-dimethylaminopyridine (DMAP) are dissolved in 100 parts of dichloromethane. Then the mixed solution was reduced to 0 o C. Add 7 parts of N,N′-dicyclohexylcarbodiimide (DCC), keep warm for 1 hour, and react overnight at room temperature. After the reaction is over, first filter the reaction solution to remove insoluble matter, then evaporate the solvent by rotary evaporation, and add saturated NaHCO to the solid residue 3 50 parts of the solution, and then extracted three times with ethyl acetate. The ethyl acetate extracts were collected and dried over anhydrous sodium sulfate overnight. The sol...

Embodiment 3

[0052] In parts by weight, the formula is as follows:

[0053] Monocarboxyl-terminated polyethylene glycol (C-PEG, molecular weight 1000) 20 parts

[0054] CdTe / CdS / ZnS quantum dot solution (wavelength 625nm, original surface ligand is mercaptopropionic acid MPA) 500 parts

[0055] Preparation Process:

[0056] In parts by weight, 6 parts of lipoic acid (TA), 20 parts of monocarboxyl-terminated polyethylene glycol (C-PEG), and 1 part of p-dimethylaminopyridine (DMAP) were dissolved in 100 parts of dichloromethane. Then the mixed solution was reduced to 0 o C. Add 7 parts of N,N′-dicyclohexylcarbodiimide (DCC), keep warm for 1 hour, and react overnight at room temperature. After the reaction is over, first filter the reaction solution to remove insoluble matter, then evaporate the solvent by rotary evaporation, and add saturated NaHCO to the solid residue 3 50 parts of the solution, and then extracted three times with ethyl acetate. The ethyl acetate extracts were coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com