Emulsified oil for hydraulic support for mines and preparation method

A hydraulic support and emulsified oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of being unable to adapt to the mining industry, the formula is old, and cannot meet the requirements, and achieves good cleaning, anti-contamination, and complete functions , good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

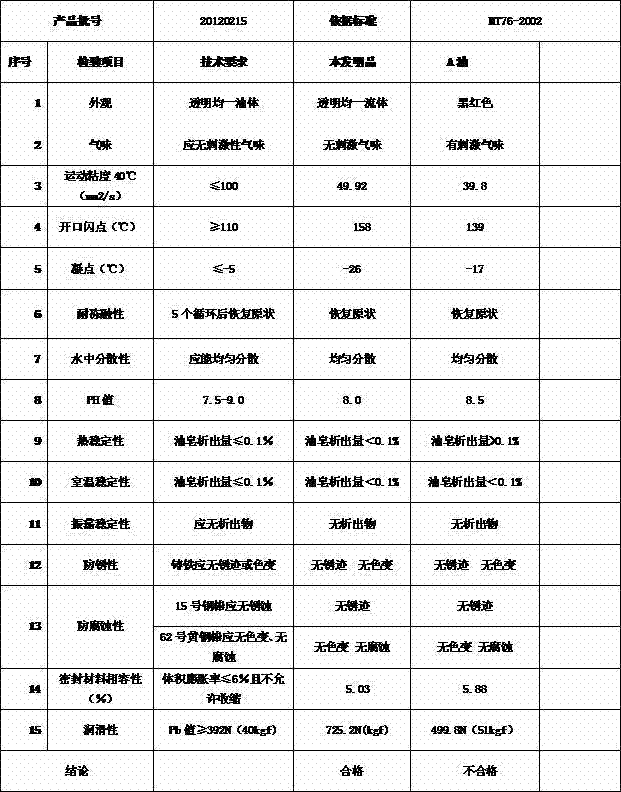

Image

Examples

Embodiment 1

[0056] An emulsified oil for mine hydraulic supports according to the present invention, the emulsified oil includes 5% (weight percent) of mineral base oil and 95% (weight percent) of additives; the additives are mixed with the following raw materials in parts by weight :

[0057] Oleic Acid: 5 parts, Triethanolamine: 6 parts, Sodium Castor Oil Soap: 5 parts, Benzotriazole: 0.3 parts, Disodium EDTA: 5 parts, Monoethanolamine: 5 parts, Urea: 5 parts, Water: 30 parts parts, POEA-15: 5 parts, water-based rust inhibitor: 6 parts, emulsified silicone oil: 0.5 parts.

[0058] Described mineral base oil is low viscosity 7# white oil.

[0059] The oleic acid is tall oleic acid.

[0060] The oil color of the emulsified oil is red agate, and the viscosity is between 35-45.

[0061] The preparation method of the emulsified oil for the above-mentioned mine hydraulic support, the method is carried out according to the following steps:

[0062] 1) Preparation of castor oil sodium soap: ...

Embodiment 2

[0074] An emulsified oil for mine hydraulic supports according to the present invention, the emulsified oil includes 15% (weight percent) of mineral base oil and 85% (weight percent) of additives; the additives are made by mixing the following raw materials in parts by weight :

[0075] Oleic Acid: 15 parts, Triethanolamine: 12 parts, Sodium Castor Oil Soap: 10 parts, Benzotriazole: 0.5 parts, Disodium EDTA: 12 parts, Monoethanolamine: 7 parts, Urea: 8 parts, Water: 50 parts parts, POEA-15: 8 parts, water-based rust inhibitor: 15 parts, emulsified silicone oil: 0.8 parts. Described mineral base oil is low viscosity 7# white oil.

[0076] The oleic acid is tall oleic acid.

[0077] The oil color of the emulsified oil is red agate, and the viscosity is between 35-45.

[0078] The preparation method of the emulsified oil for the above-mentioned mine hydraulic support, the method is carried out according to the following steps:

[0079] 1) Preparation of castor oil sodium soap...

Embodiment 3

[0091] An emulsified oil for mine hydraulic support according to the present invention, the emulsified oil includes 10% (weight percent) of mineral base oil and 90% (weight percent) of additives; the additives are mixed with the following raw materials in parts by weight :

[0092] Oleic Acid: 10 parts, Triethanolamine: 9 parts, Sodium Castor Oil Soap: 8 parts, Benzotriazole: 0.4 parts, Disodium EDTA: 9 parts, Monoethanolamine: 6 parts, Urea: 7 parts, Water: 40 parts parts, POEA-15: 7 parts, water-based rust inhibitor: 11 parts, emulsified silicone oil: 0.7 parts.

[0093] Described mineral base oil is low viscosity 7# white oil.

[0094] The oleic acid is tall oleic acid.

[0095] The oil color of the emulsified oil is red agate, and the viscosity is between 35-45.

[0096] The preparation method of the emulsified oil for the above-mentioned mine hydraulic support, the method is carried out according to the following steps:

[0097] 1) Preparation of castor oil sodium soa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com