Device and method for detecting iron ore raw material

A detection device and raw material technology, which can be applied in the direction of removing certain components, such as weighing, etc., can solve the problems of high temperature, poor operation stability, and balance damage, and achieve the effects of low working environment temperature, high detection accuracy and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention discloses a detection device and method for detecting iron ore raw materials to detect the reducibility and free reduction expansion of iron ore raw materials; Moved to the bottom of the furnace.

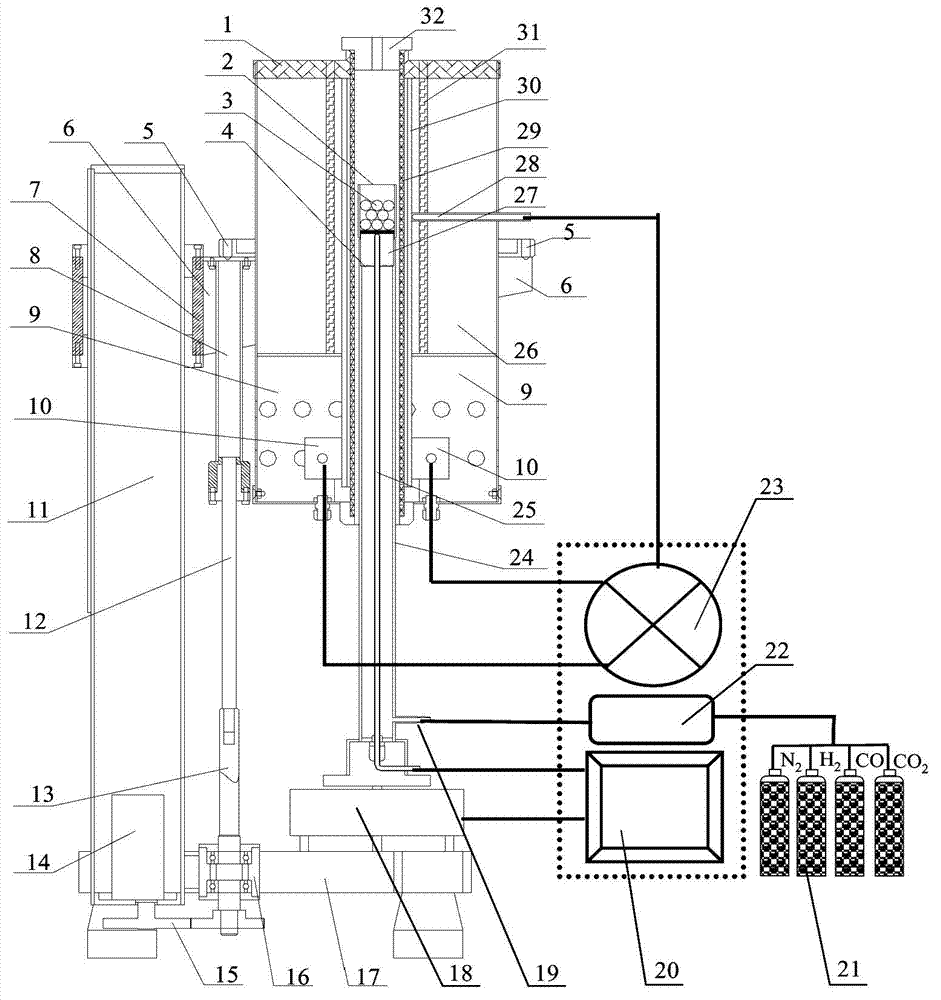

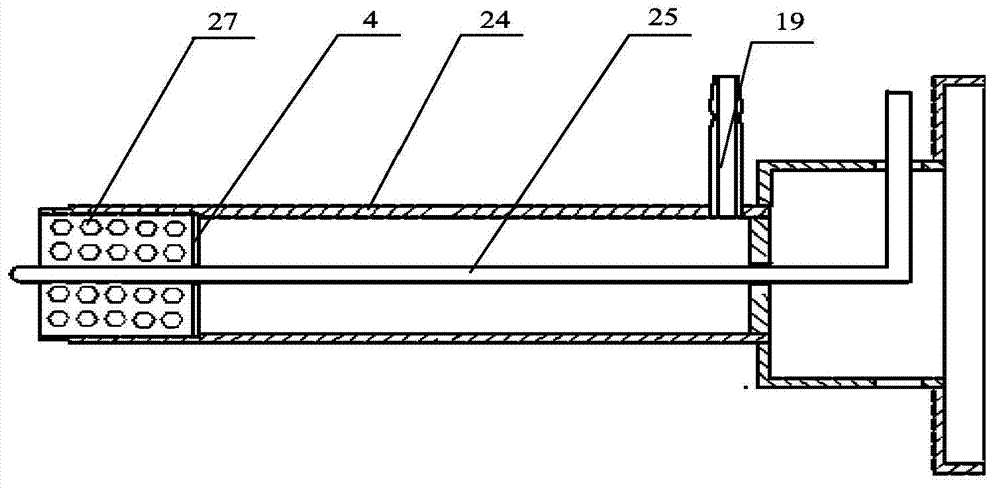

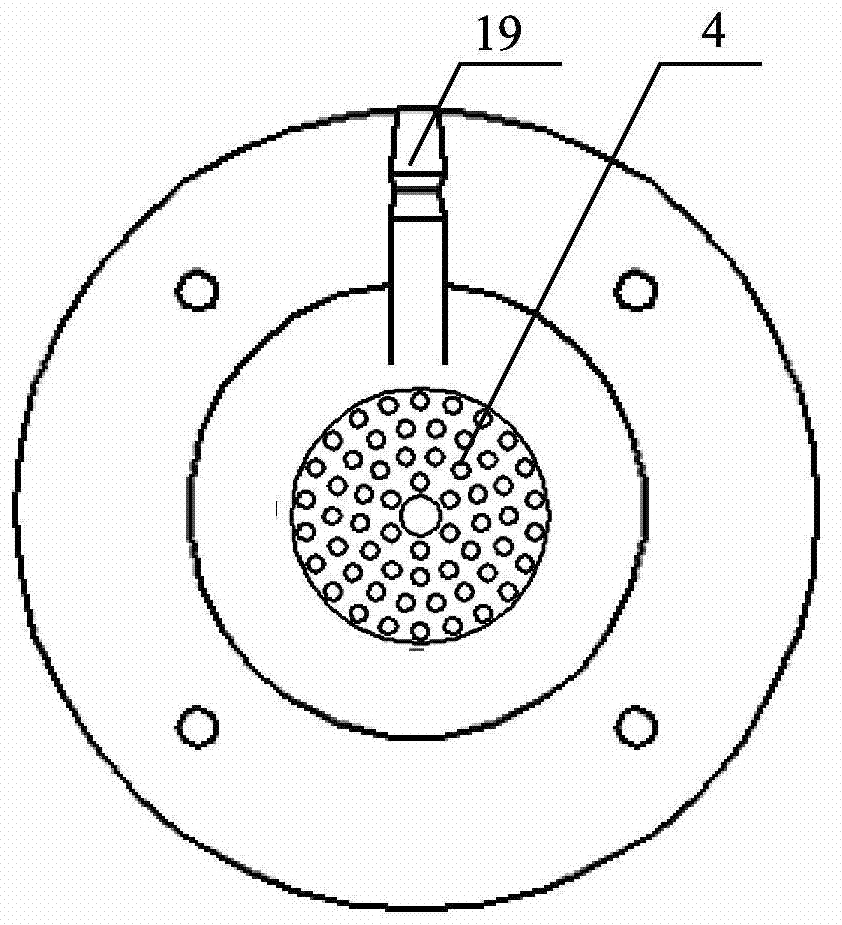

[0025] refer to Figure 1 to Figure 4 , The detection device provided by the present invention includes a vertical electric furnace system, a mechanical lifting system, an electronic balance, a lifting riser system, a computer control system, and a gas supply system.

[0026] The shaft furnace electric furnace system includes: furnace cover 1, furnace shell 9, terminal post 10, refractory material 26, furnace temperature measuring thermocouple 28, furnace tube 29, heating element 30, protection tube 31 and heat preservation cover 32; the mechanical lifting system includes : leveling ring 5, lifting table 6, sliding sleeve 7, nut sleeve 8, column 11, screw 12, transmission shaft 13, motor 14, transmission gear 15, fixing piece 16, base 17 and electronic balance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com