Automatic test system and method for vacuum stability

A technology of automatic testing and vacuum stability, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of error in test results, inability to guarantee accuracy of test data, inability to accurately reflect the performance of sample materials, etc., to achieve guaranteed accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

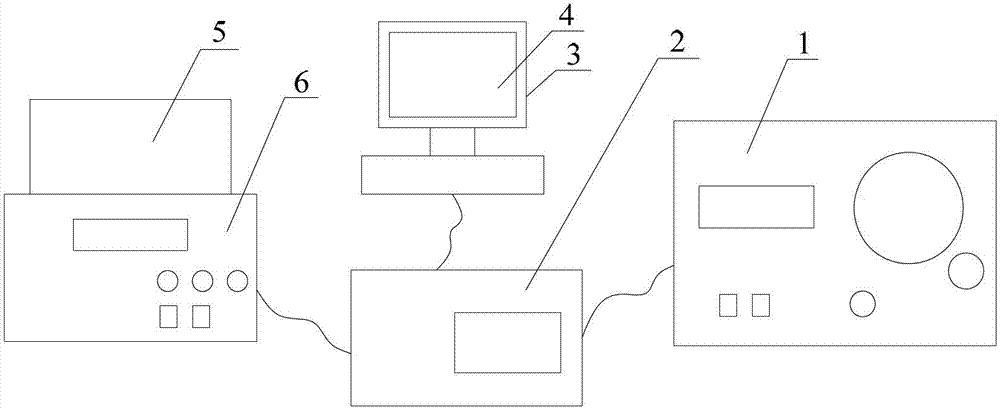

[0031] Such as figure 1 As shown, the automatic test system of the vacuum stability of the present invention comprises a constant temperature bath device, and the constant temperature bath device is the same as the constant temperature bath device currently used for the sample to be tested to be heated by a constant temperature bath, including a constant temperature bath furnace body 5 and a temperature Control cabinet6. Described constant temperature bath furnace body 5 is connected on the temperature control cabinet 6, puts into the constant temperature bath furnace body 5 after the test tube with the sample to be tested is evacuated during use, and the constant temperature bath furnace body 5 is heated by the temperature control cabinet 6, The test tube can then be heated in a constant temperature bath.

[0032] In order to realize automatic control, the temperature control cabinet 6 can automatically control the heating temperature and the heating time to the constant tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com