Water ions sensor

A sensor, water ion technology, applied in the direction of material resistance, can solve the problems of high cost, inability to wire welding, large electrode spacing error, etc., to achieve good welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

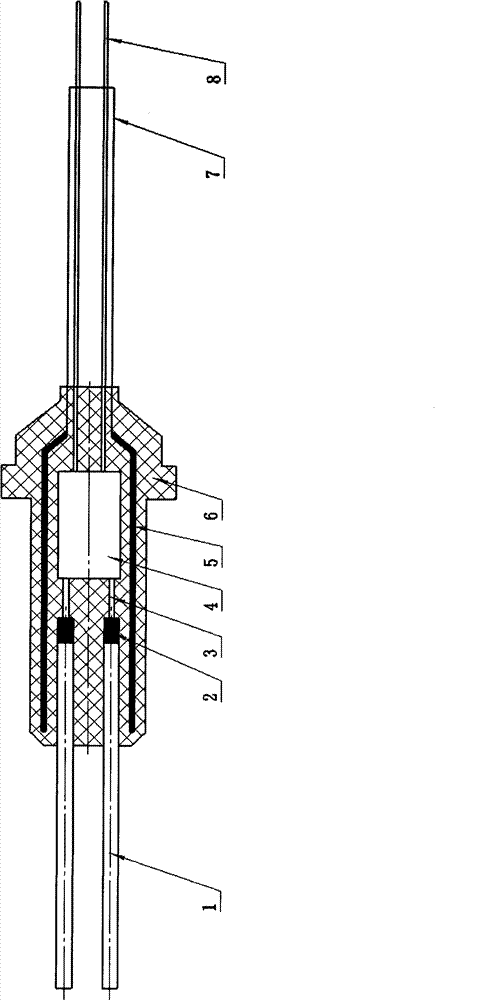

[0014] As shown in the drawings, the water ion sensor of the present invention uses two traditional electrodes 1 , one positive and one negative. In order to weld the electrode 1 and the wire 3 to reduce the contact resistance, a transition metal 2 is newly used to weld the connection between the electrode 1 and the wire 3 , one end of the transition metal 2 is welded to the electrode 1 , and the other end is welded to the wire 3 . In order to reduce the impact of interference on sensor accuracy, a conversion module 4 is added. The analog input terminal of the conversion module 4 is connected to the other end of the wire 3, so that the analog signal collected by the electrode 1 is converted into a digital signal with strong anti-interference energy, which can be transmitted over a long distance, and can be easily interfaced with the host computer or instrument. Analog standard signal. The output end of the conversion module 4 is connected to a wire 8 through which a digital s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com