Ultra-thin servo motors for elevator door operators

A technology for servo motors and elevator door operators, which is applied to electromechanical devices, electrical components, and electric components, etc., can solve the problems of difficult stator processing, poor stator waterproof, moisture-proof, corrosion-resistant performance, and difficulty in disassembly and assembly. The tank full rate and production efficiency, heat dissipation and anti-corrosion ability are enhanced, which is beneficial to the effect of space layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

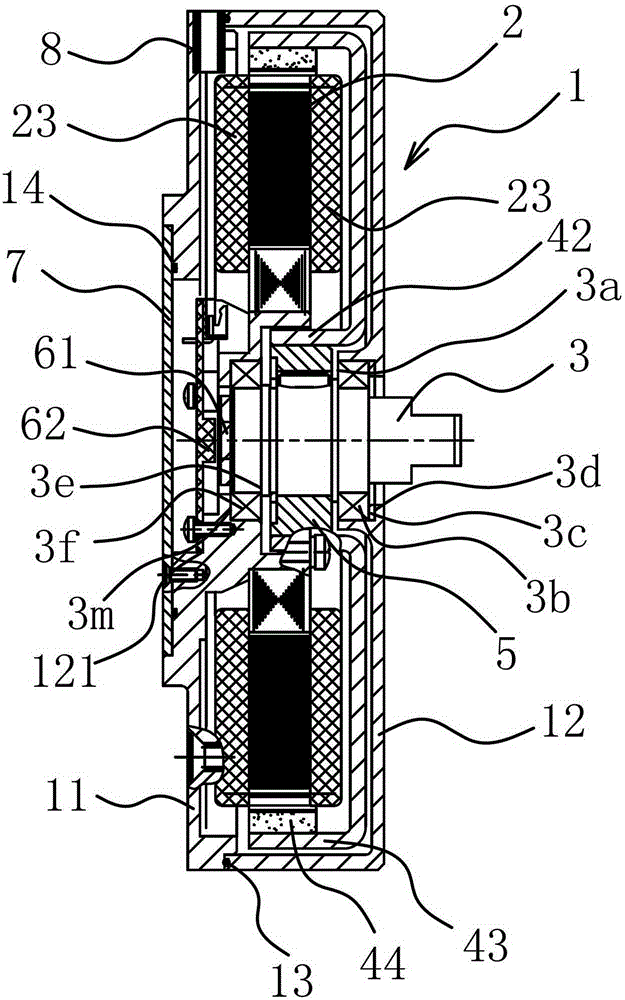

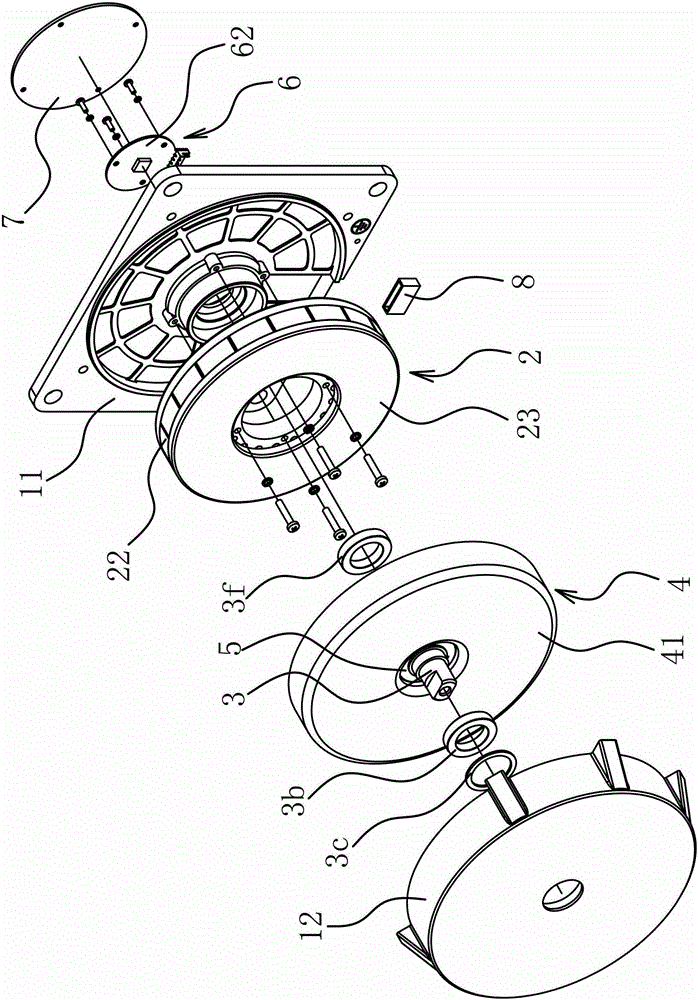

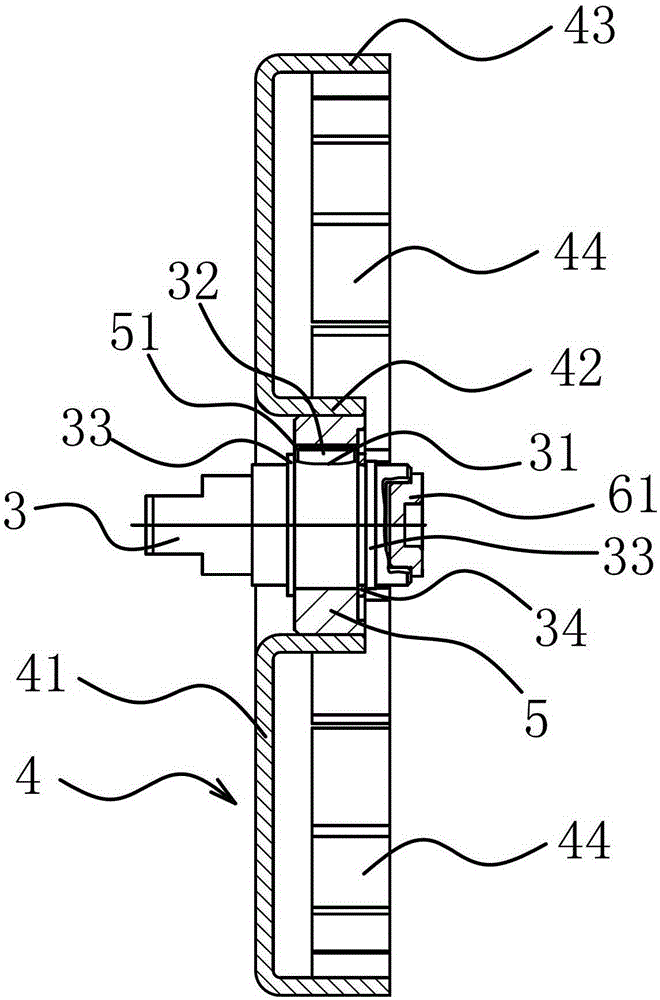

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as Figure 1-3 As shown, the ultra-thin servo motor suitable for the elevator door machine includes a motor housing 1, a stator 2 is fixed inside the motor housing 1, a rotating shaft 3 is pierced through the stator 2, and a rotor is fixed on the rotating shaft 3 4 and one end of the rotating shaft 3 extends out of the motor casing 1 . In order to reduce the weight of the servo motor and reduce the volume of the servo motor, the motor housing 1 here is flat, the stator 2 is an annular disk, and the rotor 4 is a flat annular cover and is sleeved on the stator 2 . Therefore, the ultra-thin servo motor suitable for the elevator door machine has a flat shape as a whole, a short axial dimension, and a compact and light structure.

[0024] In order to achieve accurate positioning and convenient control, the servo motor also in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com