Debugging system for motor

A debugging system and motor-driven technology, applied in control systems, control generators, vector control systems, etc., can solve problems such as difficulty in meeting the requirements of anti-interference and real-time performance, and achieve the effect of convenient fault diagnosis and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

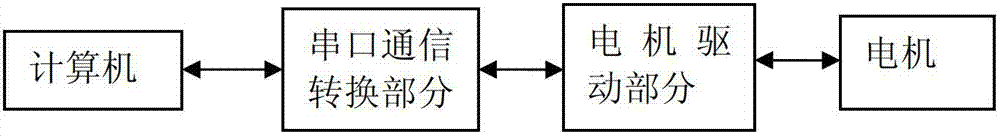

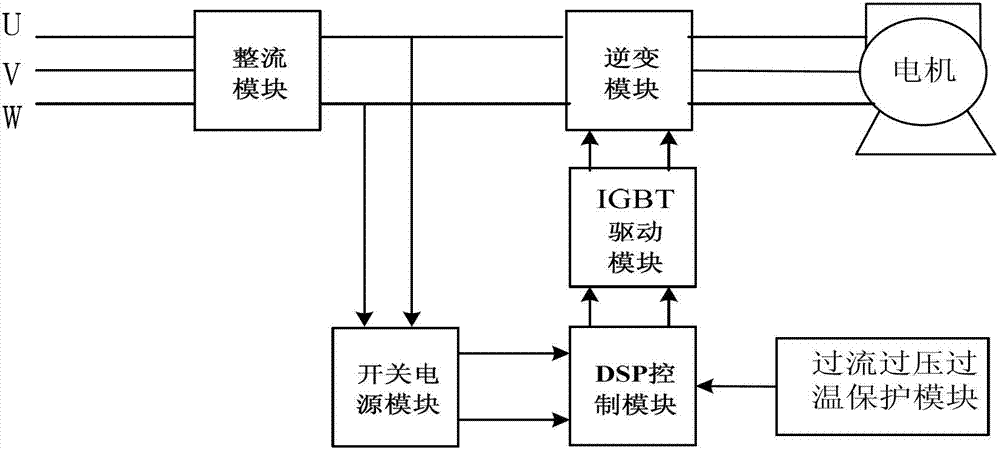

[0029] Such as figure 1 As shown, the motor debugging system of the present invention includes a computer (LabVIEW software is installed), a motor drive part and a serial port communication conversion part, such as figure 2 As shown, the motor drive part includes a DSP control module, a rectification module, an IGBT drive module, an inverter module, a switching power supply module, and an overcurrent, overvoltage, and overtemperature protection module. The rectification module is connected to the motor through an inverter module. The rectifier module is connected to the DSP control module through the switching power supply module; the IGBT drive module is connected to the inverter module and the DSP control module respectively, and the overcurrent, overvoltage and overtemperature protection module is connected to the DSP control module.

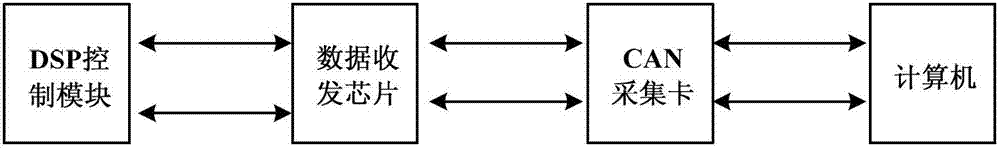

[0030] Such as image 3 As shown, the data transceiver chip (using PCA82C250) and the CAN acquisition card (using USBCAN-II) included in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com