Method for preventing whole-house separate purifying device film from being polluted

A purification device and membrane pollution technology, which is applied in the field of water purification, can solve the problems of poor antifouling effect and short membrane service life, and achieve the effects of prolonging service life, reducing operating costs and ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

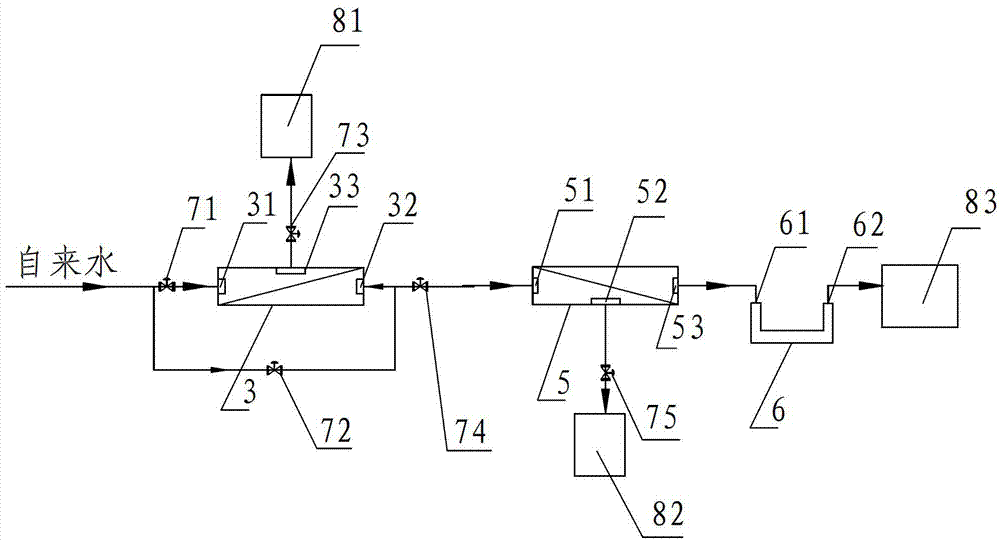

[0022] A whole house quality separation and purification device, such as figure 1 Shown, comprise connecting ultrafiltration membrane unit 3, nanofiltration membrane unit 5, ultraviolet sterilizer 6 successively, wherein tap water outlet is connected with the water inlet 31 of ultrafiltration membrane unit 3, the water production port 32 of ultrafiltration membrane unit 3 is connected with The water inlet 51 of the nanofiltration membrane unit 5 is connected, the water production port 52 of the nanofiltration membrane unit 5 is connected with the water inlet 61 of the ultraviolet sterilizer 6, and the water outlet 62 of the ultraviolet sterilizer 6 is connected with the domestic drinking water port 83, and the The concentrated water port 33 of the ultrafiltration membrane unit 3 and the concentrated water port 53 of the nanofiltration membrane unit 5 are respectively connected to the domestic primary water port 81 and the domestic secondary water port 82 . The household primar...

Embodiment 2

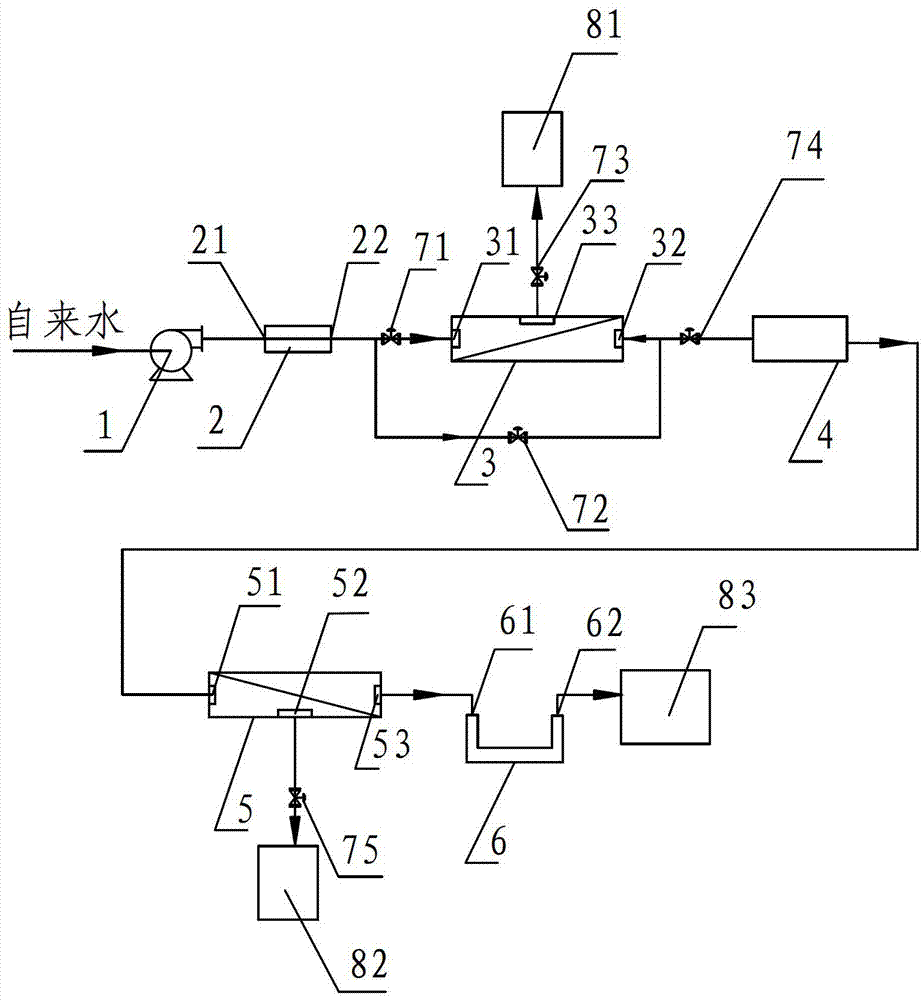

[0030] A whole house quality separation and purification device, such as figure 2 As shown, it includes sequentially connected booster pump 1, microfiltration filter 2, ultrafiltration membrane unit 3, activated carbon filter 4, nanofiltration membrane unit 5, and ultraviolet sterilizer 6, wherein the booster pump 1 is connected to the tap water outlet Between the water inlet 21 of the microfiltration filter 2, the water outlet 22 of the microfiltration filter 2 is connected with the water inlet 31 of the ultrafiltration membrane unit 3, and the water production port 32 of the ultrafiltration membrane unit 3 is connected with the nanofiltration membrane unit 5 The activated carbon filter 4 is connected between the water inlet 51 of the nanofiltration membrane unit 5, the water inlet 52 of the nanofiltration membrane unit 5 is connected with the water inlet 61 of the ultraviolet sterilizer 6, and the water outlet 62 of the ultraviolet sterilizer 6 is connected with the domestic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com