Casting method of valve cover casting

A pouring method and valve cover technology, which is applied in the directions of casting molds, casting mold components, casting molding equipment, etc., can solve the problems that the yield is difficult to reach 80%, the production progress is affected, and the coating is uneven, and the defects such as slag holes can be eliminated. , Improve production efficiency, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

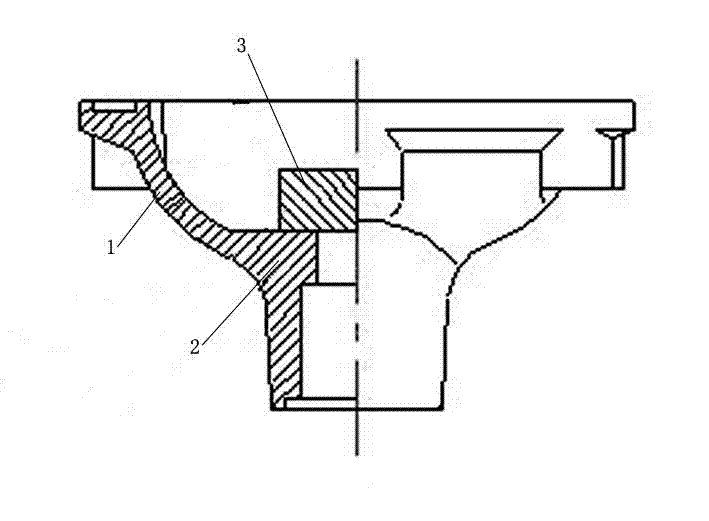

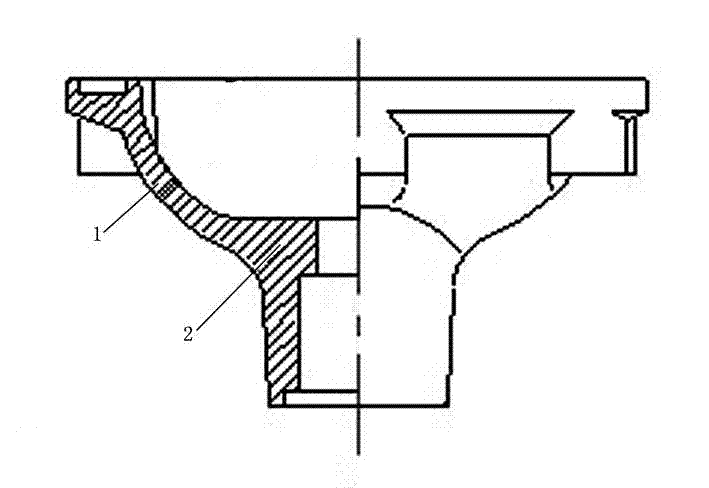

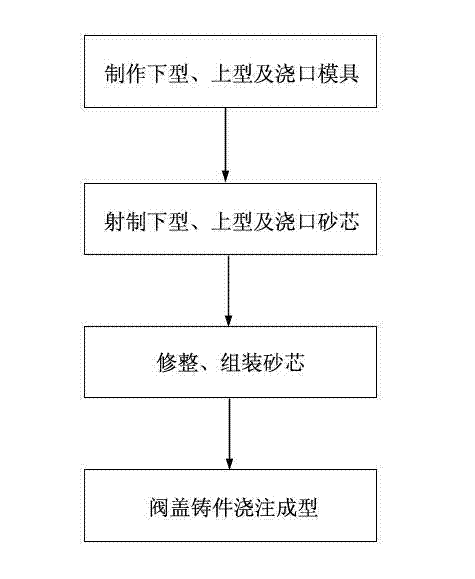

[0021] In order to further reveal the technical solutions of the present invention, the following describes the implementation of the present invention in detail in conjunction with the accompanying drawings: image 3 Shown, a kind of pouring method of bonnet casting, its specific steps are:

[0022] (1) First, carry out process and mold design according to the principle of balanced solidification, and make lower mold, upper mold and gate mold;

[0023] (2) Shoot the lower sand core, upper mold sand core and gate sand core on the corresponding hot core box core shooter;

[0024] (3) Trim and assemble the sand core, clamp the assembled sand core with a clamp, and cast the bonnet casting into shape.

[0025] The gate of the valve cover mold includes an ingate, which adopts a hot-side poured ingate. The width of the ingate is not less than 40mm, the thickness is not more than 7mm, and the length is less than 10mm.

[0026] The gate of the bonnet mold includes a sprue, the diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com