Method for preparing compound of zinc oxides and silver nano

A silver nano-composite technology, which is applied in the field of organic matter-polyethylene polyamine, can solve the problems of small number and disadvantages of Ag nanoparticles, and achieve the effect of good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Weigh 1.4187g of polyethylene polyamine into 30mL of deionized water, stir to dissolve;

[0029] 2) Weigh 2.0869g of ZnAc 2 2H 2 O was added to solution 1), and 10 mL of absolute ethanol was added;

[0030] 3) Weigh 0.1451g of AgNO 3 Dissolve in solution 2), continue to stir for 1h;

[0031] 4) Transfer the solution 3) to the reaction kettle, react at 120°C for 6 hours, and cool naturally after the reaction;

[0032] 5) Centrifugal washing (8000r / min, 5min), washed 3 times with water, washed 3 times with alcohol, and dried naturally;

Embodiment 2-3

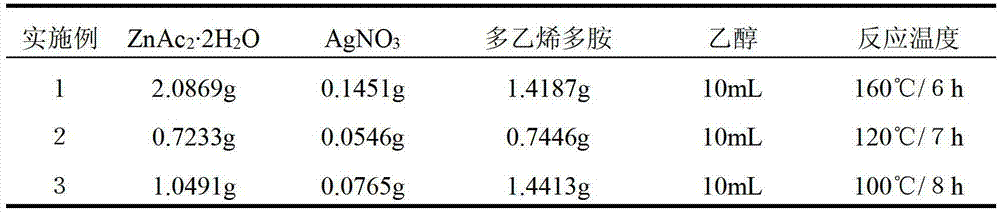

[0033] Embodiment 2-3: by the method for embodiment 1, reaction condition is as follows:

[0034] Conditional distribution of the example

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com