Welding method for 10CrMo9-10 steel

A welding method and welding groove technology, applied in welding equipment, arc welding equipment, workpiece edge parts, etc., can solve the problem of high temperature durability strength and creep limit, physical properties resistance to hydrogen and oxidation, and resistance to brittle fracture It is difficult to be similar to the base metal to achieve high production efficiency, prevent cold cracking, and improve the welding process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described with reference to the accompanying drawings. In the drawings of the specification, elements or devices having similar structures or functions will be denoted by the same reference numerals. The drawings are only for the convenience of illustrating various embodiments of the present invention, and are not intended to describe the present invention exhaustively, nor limit the scope of the present invention.

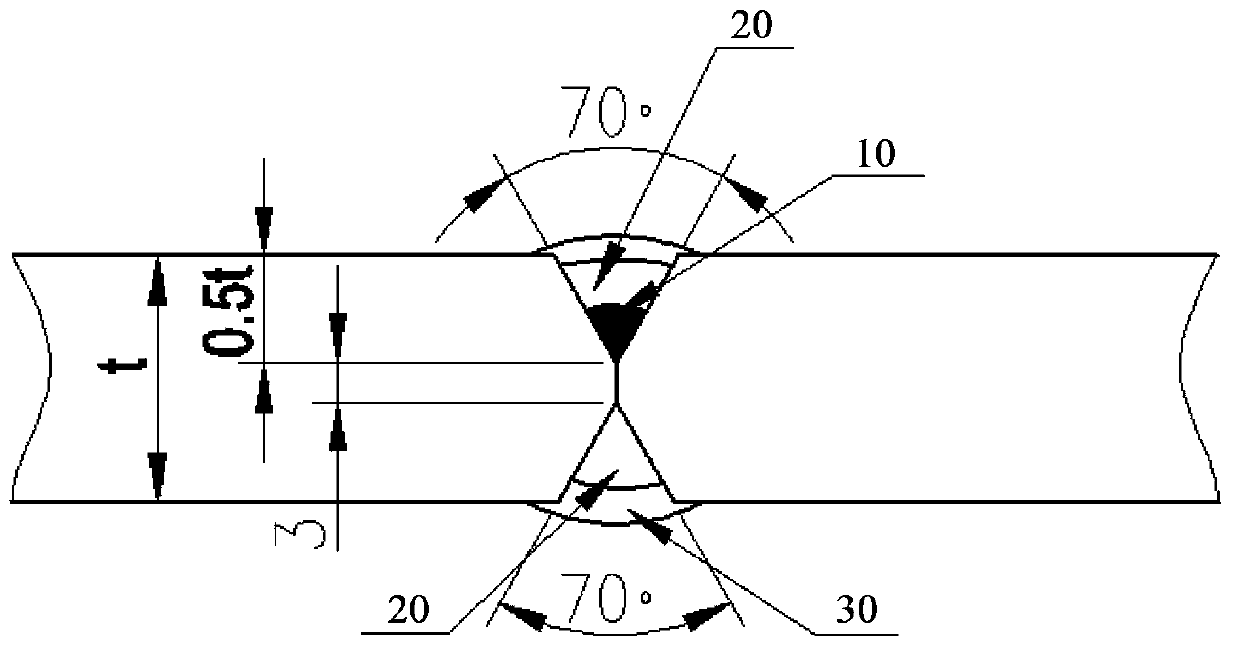

[0032] figure 1 The schematic positions of two parts to be welded under a specific embodiment of the present invention are shown. Below with reference to accompanying drawing, introduce welding method of the present invention, it may further comprise the steps:

[0033] Step 110, the technician places two 10CrMo9-10 steel pieces to be welded horizontally, processes the welding groove into an X-shaped groove, and mills the pieces to be welded with an edge milling machine, with a groove angle of 70° (unilateral ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com