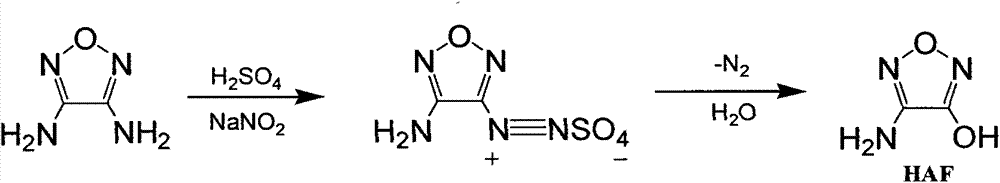

Synthetic method of 3-amino-4-hydroxyfurazan

A synthetic method and technology of hydroxyfuran, which is applied in the field of synthesis of 3-amino-4-hydroxyfuran, can solve the problems of low reaction yield, reduced reaction yield, increased by-products, etc., and achieve simple post-treatment process and high purity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 4g of 3,4-diaminofurazan and 45g of 24% (mass) sulfuric acid were added to the reaction flask under stirring, and at a temperature of -3°C to 3°C, 30mL of an aqueous solution containing 1.38g of sodium nitrite was added dropwise to the reaction flask. Control the dropping time for 2 hours. After adding the aqueous solution of sodium nitrite dropwise, react at a temperature of 0°C for 2 to 3 hours. At this time, the reaction liquid is pink; stop cooling and naturally heat up to 20°C to 25°C under stirring. Use a water bath to heat up to 50°C, and a large amount of nitrogen bubbles will emerge. After continuing to stir and react for 15 minutes, cool down in an ice-water bath to cool down to 0°C-5°C, stir for 30 minutes, and filter. The obtained filter cake is washed and vacuum-dried to After constant weight, 3.69 g of pale yellow-green solid 3-amino-4-hydroxyfurazan was obtained, with a yield of 91.4%.

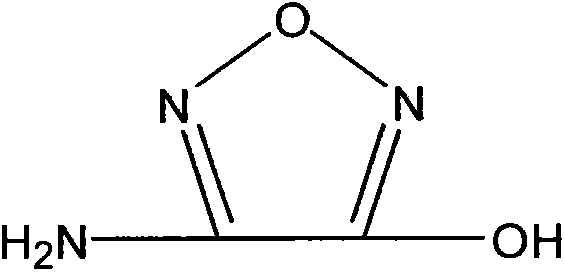

[0021] Structure Identification:

[0022] Infrared (KBr, cm -1 ): ...

Embodiment 2

[0032] Add 4g of 3,4-diaminofurazan and 45g of 20% (mass) sulfuric acid into the reaction flask under stirring, and add 30mL of an aqueous solution containing 1.38g of sodium nitrite dropwise into the reaction flask at a temperature of -3°C to 3°C. Control the dropping time for 1.5h. After adding the aqueous solution of sodium nitrite dropwise, react at 0°C for 2-3h. At this time, the reaction liquid is pink; stop cooling and naturally heat up to 20°C-25°C under stirring. , use a water bath to heat up to 40°C, a large amount of nitrogen bubbles will emerge, continue to stir and react for 10 minutes, then cool down in an ice-water bath to cool down to 0°C-5°C, stir for 30 minutes, filter, and the obtained filter cake is washed and vacuum-dried After reaching a constant weight, 3.22 g of light yellow-green solid 3-amino-4-hydroxyfurazan was obtained, with a yield of 79.6%.

Embodiment 3

[0034] Add 4g of 3,4-diaminofurazan and 45g of 30% (mass) sulfuric acid into the reaction flask under stirring, and add 30mL of an aqueous solution containing 1.38g of sodium nitrite dropwise into the reaction flask at a temperature of -3°C to 3°C. Control the dropping time to 21.5 hours. After adding the aqueous solution of sodium nitrite dropwise, react at a temperature of 0°C for 2-3 hours. At this time, the reaction liquid is pink; stop cooling and naturally heat up to 20°C-25°C under stirring. , use a water bath to heat up to 40°C, a large amount of nitrogen bubbles will emerge, continue to stir and react for 30 minutes, then cool down in an ice-water bath to cool down to 0°C-5°C, stir for 30 minutes, filter, and the obtained filter cake is washed and vacuum-dried After reaching a constant weight, 3.38 g of light yellow-green solid 3-amino-4-hydroxyfurazan was obtained, with a yield of 83.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com