Method for making aged vinegar by using extrusion of raw materials

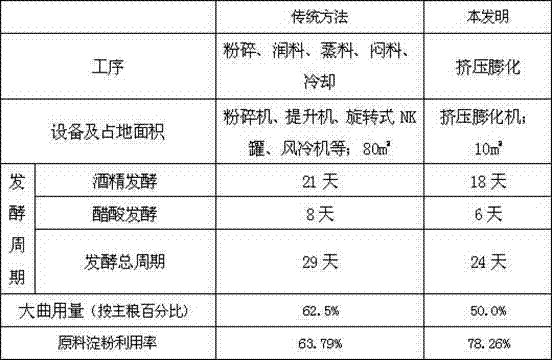

A technology of extrusion puffing and aged vinegar, which is applied in the preparation of vinegar and other directions, can solve the problems of long production cycle, complicated process and low utilization rate of starch, and achieve the effects of improving utilization rate, simplifying process and reducing dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for brewing mature vinegar by extruding and puffing raw materials, comprising the following steps:

[0026] (1) Raw material puffing: Sorghum is puffed in an extrusion extruder to obtain staple food;

[0027] (2) Mixing koji: Mix and mix the main grain and water according to the mass ratio of 1:0.6, mix the Daqu with 62% of the main grain mass and water in the same proportion for 2 hours to obtain the activated bacteria, add the activated bacteria after mixing In the staple food, obtain fermented material;

[0028] (3) Alcoholic fermentation: transfer the fermented material into the alcohol fermentation tank, rake for the first 3 days, then control the product temperature at 28°C, the fermentation room temperature at 22°C, and the fermentation period of 18 days to control the alcohol in the fermented mash The degree is 10°;

[0029] (4) Acetic acid fermentation: After the alcoholic fermentation is completed, add 63% bran and 30% rice bran to the fermented mat...

Embodiment 2

[0034] A method for brewing mature vinegar by extruding and puffing raw materials, comprising the following steps:

[0035] (1) Raw material puffing: Sorghum is puffed in an extrusion extruder to obtain staple food;

[0036] (2) Mixing koji: Mix the staple food and water according to the mass ratio of 1:0.62, and mix the Daqu with 60% of the mass of the staple food and water in the same proportion for 2 hours to obtain the activated bacteria. Add the activated bacteria to the mix In the staple food, obtain fermented material;

[0037] (3) Alcoholic fermentation: transfer the fermented material into the alcohol fermentation tank, and rake for the first 3 days, then control the product temperature at 30°C, the fermentation room temperature at 20°C, and the fermentation period of 18 days to control the alcohol in the fermented mash The degree is 9°;

[0038] (4) Acetic acid fermentation: After the alcoholic fermentation is completed, add 60% bran and 33% rice bran to the fermen...

Embodiment 3

[0043] A method for brewing mature vinegar by extruding and puffing raw materials, comprising the following steps:

[0044] (1) Raw material puffing: Sorghum is puffed in an extrusion extruder to obtain staple food;

[0045] (2) Mixing koji: Mix and mix the staple food and water according to the mass ratio of 1:0.65, mix the Daqu with 62.5% of the mass of the staple food and water in the same proportion for 2 hours to obtain the activated bacteria, add the activated bacteria after mixing In the staple food, obtain fermented material;

[0046] (3) Alcoholic fermentation: transfer the fermented material into the alcohol fermentation tank, and rake for the first 3 days, then control the product temperature at 32°C, the fermentation room temperature at 23°C, and the fermentation period of 18 days to control the alcohol in the fermented mash The degree is 9°;

[0047] (4) Acetic acid fermentation: After the alcoholic fermentation is completed, add 70% bran and 40% rice bran to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com