Tail-gas strong-ionization and purifying gas production assisted zero-emission energy saving machine master device

A purifier and zero-emission technology, which is applied to exhaust devices, mufflers, chemical instruments and methods, etc., can solve the problems of low recycling rate and high energy consumption, and achieves high practicability, stable performance and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

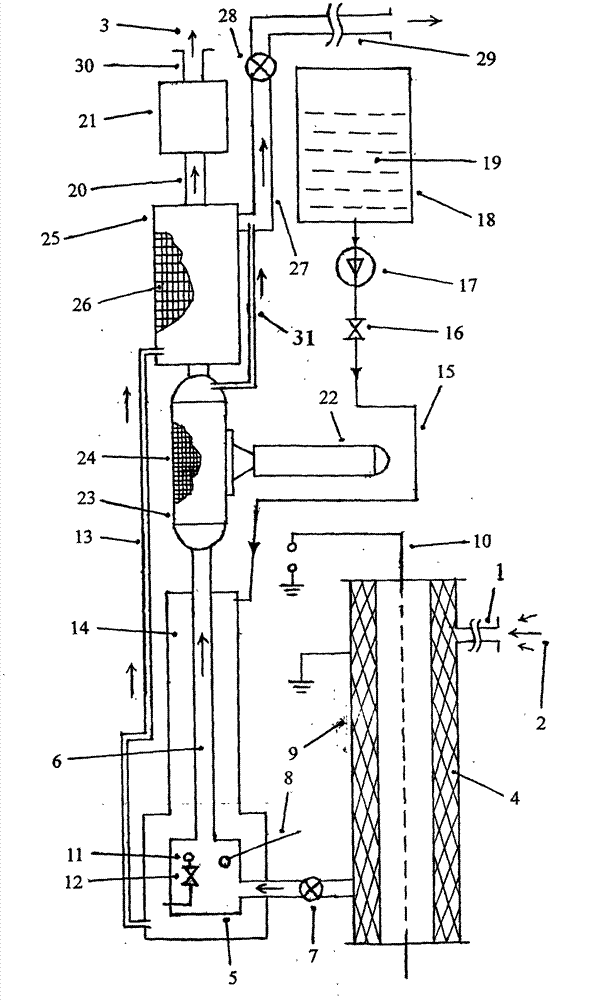

[0010] exist figure 1Among them, this device uses waste heat of exhaust gas to heat highly polluted and highly toxic organic waste liquid water alcohol to make fuel steam system, waste heat utilizes low-temperature catalytic purification plasma high-energy electron discharge catalytic high-energy collision ionization collaborative purification system, ultra-high temperature incineration purification pulse combustion Thermal ionization purification system, high-energy electron strong photoionization purification of carbon dioxide into fuel photocatalytic purification system, waste heat using water alcohol vapor to make mixed gas high-energy fuel energy-saving device to improve engine power %) consists of 5 major systems. The first system consists of energetic water-alcohol agent mixed solution (19), energetic water-alcohol agent mixed solution tank (18), high-pressure pump (17), water-alcohol agent output solenoid valve pipeline (16), water-alcohol agent agent high-pressure ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com