White light source based on laser

A technology of white light source and laser, which is applied in the field of white light source, can solve the problems of low light output efficiency and inability to transmit light remotely, and achieve the effects of improving luminous efficiency, high luminous intensity, and uniform color temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with accompanying drawing and embodiment:

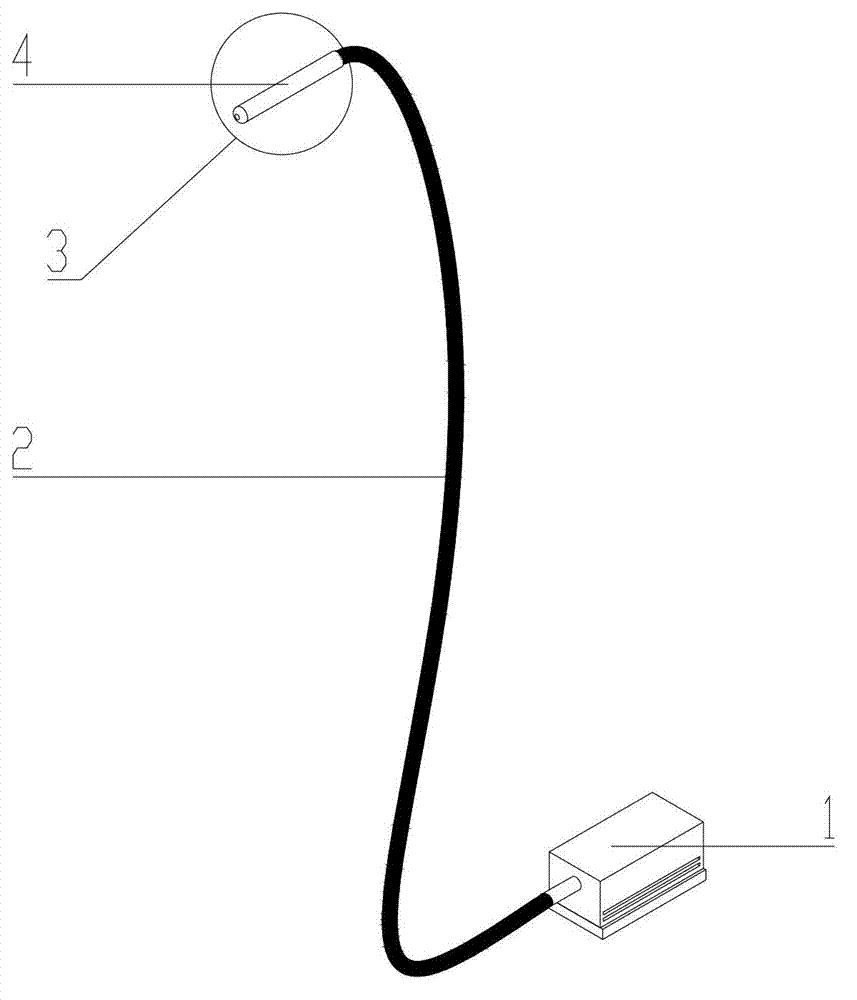

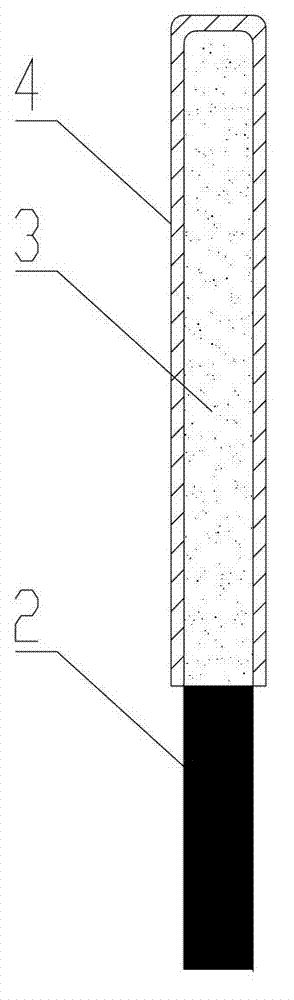

[0022] As shown in the figure, a laser-based white light source of the present invention includes a laser 1 and an optical fiber 2 for transmitting laser light. One end of the optical fiber 2 is coupled to the output port of the laser 1. The optical fiber 2 is provided with a The light-emitting part 3 formed after the light-leakage treatment is provided with a phosphor layer 4 on the outer surface of the light-emitting part 3 which can modulate the colored laser light to emit white light. The light leakage treatment is chemical corrosion treatment or physical processing. The fluorescent powder layer includes fluorescent powder and silica gel or epoxy resin that encapsulates and fixes the fluorescent powder. In the present embodiment, a blue light laser is preferred as a light source. During work, the laser light emitted by the laser 1 is introduced from a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com