Composition for wire coating material, insulated wire and wire harness

A technology of coating materials and compositions, applied in the direction of insulating cables, plastic/resin/wax insulators, insulators, etc., can solve the problems of expensive equipment, expensive electron beam cross-linking devices, and rising product costs to achieve heat resistance High, high gel fraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

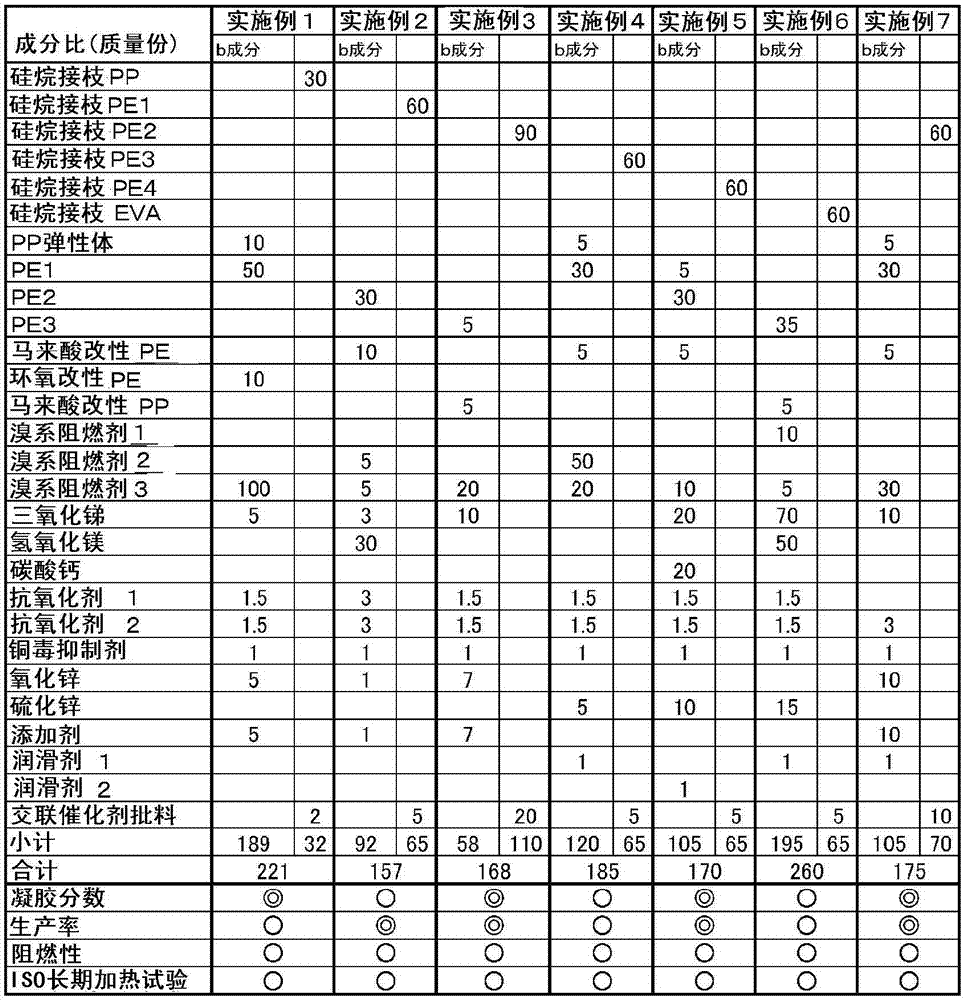

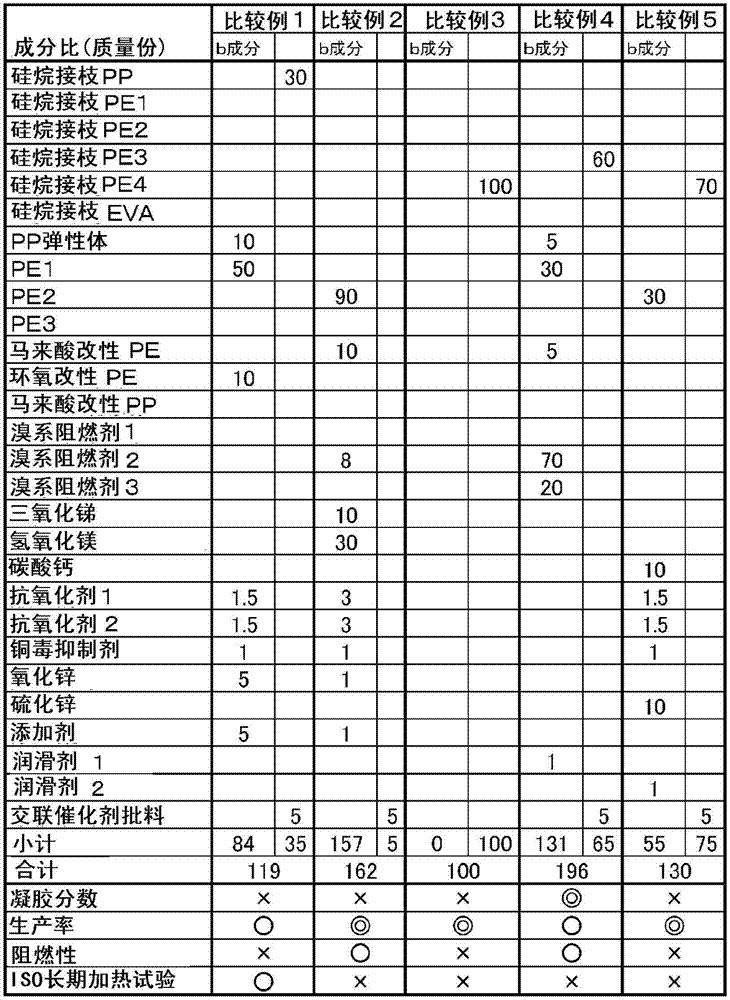

[0066] Examples and comparative examples of the present invention are shown below. The present invention is not limited thereto.

[0067] [Test material and manufacturer, etc.]

[0068] The test materials used in the present examples and comparative examples are shown together with manufacturers, trade names, and the like.

[0069] ・Silane-grafted PP [manufactured by Mitsubishi Chemical Corporation, trade name "Linklon XPM800HM"]

[0070] · Silane-grafted PE1 [manufactured by Mitsubishi Chemical Corporation, trade name "Linklon XLE815N" (LLDPE)]

[0071] Silane-grafted PE2 [manufactured by Mitsubishi Chemical Corporation, trade name "Linklon XCF710N" (LDPE)]

[0072] · Silane-grafted PE3 [manufactured by Mitsubishi Chemical Corporation, trade name "Linklon QS241HZ" (HDPE)]

[0073] Silane-grafted PE4 [manufactured by Mitsubishi Chemical Corporation, trade name "Linklon SH700N" (VLDPE)]

[0074] ・Silane-grafted EVA [manufactured by Mitsubishi Chemical Corporation, trade na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com