Manufacturing method of solid electrolyte

A solid electrolyte and manufacturing method technology, applied in the direction of electrolytic capacitor manufacturing, solid electrolytic capacitor, cable/conductor manufacturing, etc., can solve the problems of solid electrolyte characteristic deviation, increasing solid electrolytic capacitor characteristic deviation, unclear solid electrolyte range, etc. Achieves the effect of abnormal growth inhibition and small characteristic deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0079] 1) Preparation of polymerization solution

[0080] Mix 0.4 parts by mass of 3,4-ethylenedioxythiophene, 0.3 parts by mass of anthraquinonesulfonic acid, 30 parts by mass of water and 70 parts by mass of ethylene glycol to obtain 3,4-ethylenedioxythiophene dispersed in a liquid medium formed polymer solution.

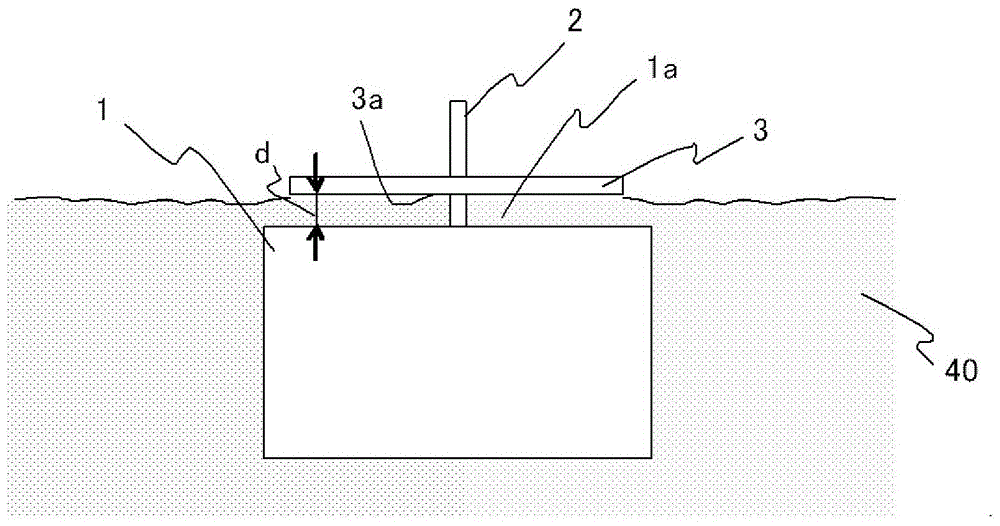

[0081] The polymerization solution was put into a polymerization container (bottom made of stainless steel, sides made of glass, width 220 mm, depth 140 mm, liquid depth 20 mm), and the liquid temperature was adjusted to 20°C.

[0082] A magnetic stirrer (ISIS Co., Ltd., リモートマルチ 60+20C type) was installed under the polymerization vessel, and 24 stirrers with a diameter of 5 mm φ x a length of 14 mm were arranged in 6 × 4 rows at intervals of 33 mm in the polymerization vessel. The aforementioned magnetic stirrer has a mode in which the stirring bar is continuously rotated, and a mode in which the stirring bar is repeatedly rotated forward and backward at an angle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com