Row-spanning self-walking riding type tea-leaf picker and working method thereof

A tea picking machine and green tea technology, which is applied to picking machines, chemical instruments and methods, harvesters, etc., can solve the problems of time-consuming and labor-consuming, and achieve the effects of improving operation speed, facilitating rapid screening, and reducing working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

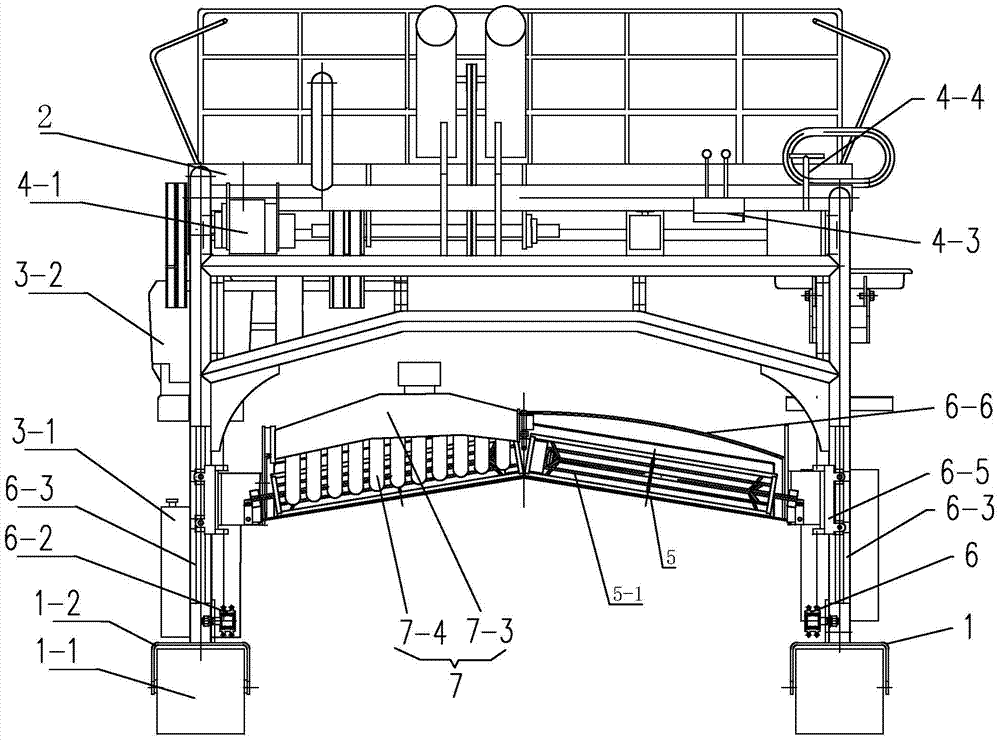

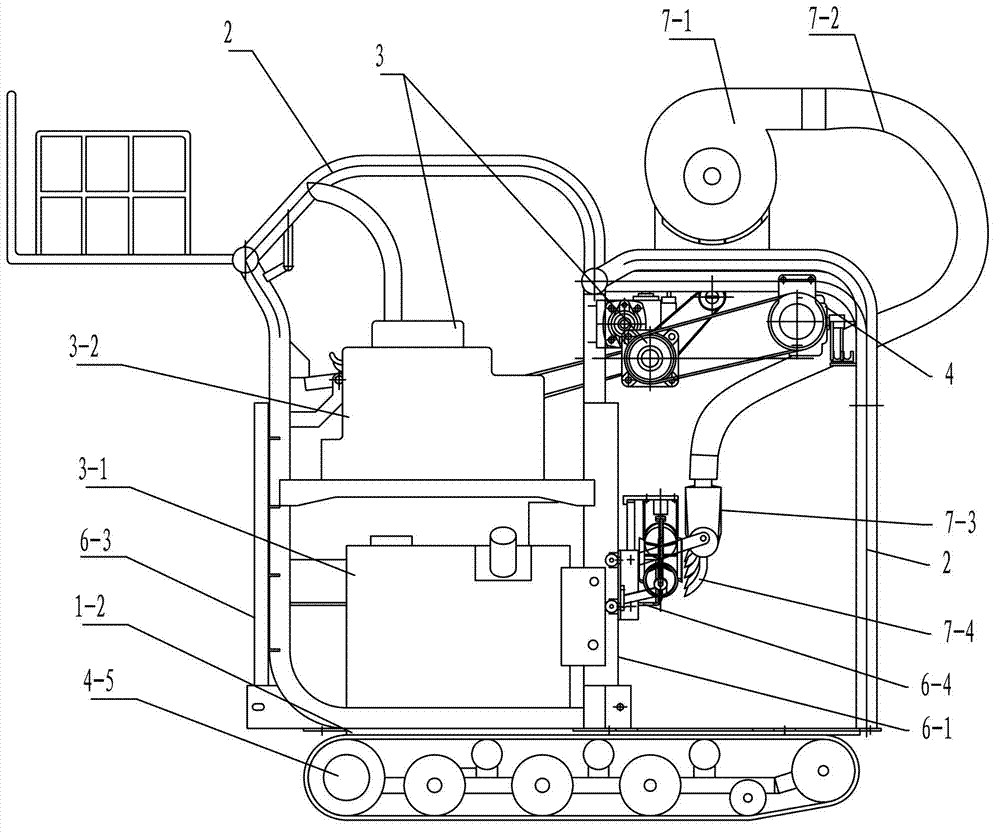

[0052] The cross-row self-propelled ride-on type tea picking machine of the present embodiment, such as Figure 1-2 As shown, it includes chassis system 1, rack system 2, power and transmission system 3, hydraulic assembly 4, tea picking mechanism 5 and its lifting system 6, tea green collecting mechanism 7, electrical control system 8 and some subsystem protection cover etc.

[0053] Frame 2 left and right sides round steel bottoms are welded on the crawler upper guard plate 1-2 of the left and right crawler assembly 1-1 of chassis 1, constitute the overall framework of tea picking machine.

[0054] Engine 3-2 is installed on the frame 2, gasoline tank 3-1 is installed on the right side of frame 2, is positioned at engine 3-2 just below, and pulley power transmission system is installed in the middle front part of frame 2 top, respectively The power is transmitted to the double fan 7-1 and the triple hydraulic pump 4-1; the battery is installed in the upper left corner of th...

Embodiment 2

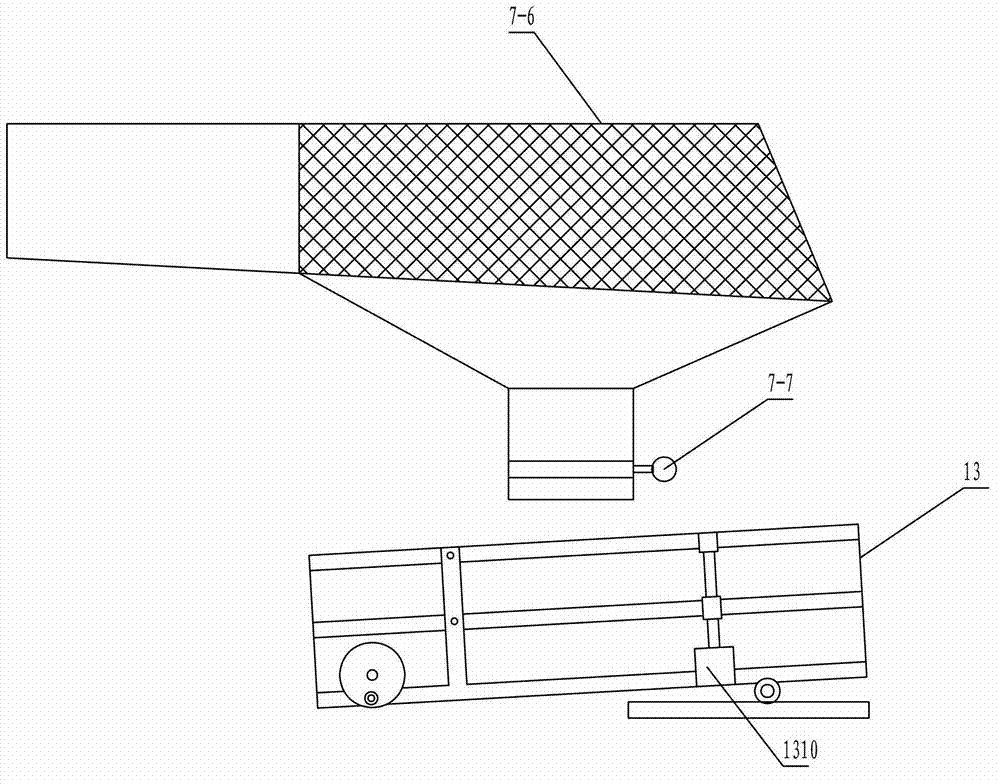

[0064] On the basis of embodiment 1, the tea picking machine of the present embodiment also includes a green tea screening mechanism 13 located below the discharge port at the bottom of the green tea collection bag 7-6; the green tea screening mechanism 13 includes Screening frame 131, the upper screen cloth 132, the lower screen cloth 133 that are arranged on this screening frame 131 up and down; The mesh size of described upper screen cloth 132 is suitable for screening out the blade and leaf stem that length is greater than 3cm; The mesh size of the following sieve 133 is suitable for screening out leaves and leaf stems with a length greater than 0.5 cm.

[0065] Below the left end of described screening frame 131 is provided with scroll wheel 134, and the outer edge of adjacent this scroll wheel 134 is fixedly provided with the power transmission shaft parallel with the central axis of this scroll wheel 134, and this transmission shaft is connected with the bottom of this s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com