Cellular purified konjac glucomannan gel food and processing method thereof

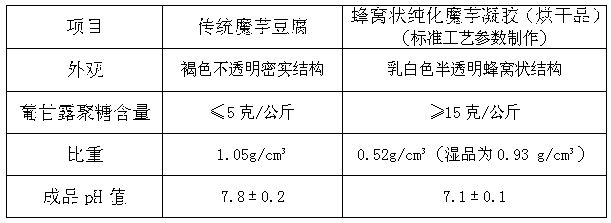

A technology of glucomannan and mannan, which is applied in the processing field of honeycomb-shaped purified konjac glucomannan gel food, can solve difficult problems such as starch retention, alkalinity, limited social use value, and loss of delicious taste , to achieve the effect of improving social use value, expanding the adaptability of the crowd, and improving food value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] On November 11, 2012, 8 kg of purified konjac gel was used to make No. 1 sample record

[0031] water 9600 ml Sodium carbonate solid 48g Konjac powder (first grade, KGM content 65%) 240g (30g / kg) stirring speed 160 rpm Sol reaction constant temperature 55℃ curing temperature 75℃ Finished product specific gravity Wet product: 0.90g / cm3 dry product 0.51 g / cm3

[0032] A、 Preparation of lye: 9600ml of clean water, 48g of solid sodium carbonate to make lye and keep the temperature at 55°C.

[0033] B、 Sprinkling of konjac fine powder: constant temperature lye (55°C), weigh 240 grams of first-grade konjac fine powder (national standard GB / T18104-2000) and evenly sprinkle it into the stirred lye, and the stirring speed is 160 rpm.

[0034] C、 Stirring reaction: After the konjac powder is sprinkled, continue to stir at 160 rpm for 14 minutes, and the reaction foam disappears. Continue to stir for 2 minutes and...

Embodiment 2

[0041] On November 11, 2012, 8 kg of purified konjac gel was produced and the record of sample No. ⑵

[0042] water 8400 ml Sodium carbonate solid 48g Konjac powder (first grade, KGM content 65%) 195g stirring speed 90 rpm Sol reaction constant temperature 40℃ curing temperature 70℃ Finished product specific gravity Wet product: 0.96g / cm3 dry product 0.71 g / cm3

[0043] A、 Preparation of lye: 8400ml of purified water, 48g of solid sodium carbonate to prepare lye and keep the temperature at 40°C.

[0044] B、 Sprinkling of konjac fine powder: constant temperature lye (40°C), weigh 195 grams of konjac fine powder (grade 1) (national standard GB / T18104-2000) and evenly sprinkle it into the stirred lye, and the stirring speed is 90 rpm.

[0045] C、 Stirring reaction: After the konjac powder is sprinkled, continue to stir at a speed of 90 rpm for 18 minutes, and the reaction foam disappears. Continue to stir for 5 minut...

Embodiment 3

[0052] On November 23, 2012, 8 kg of purified konjac gel was used to make sample record No. ⑶

[0053] water 9500 ml Sodium Hydroxide Solid + Sodium Carbonate Solid 19g+19g Konjac powder (first grade, KGM content 65%) 240g stirring speed 160 rpm Sol reaction constant temperature 55℃ curing temperature 75℃ Finished product specific gravity Wet product: 0.98g / cm3 dry product 0.86 g / cm3

[0054] A、 Preparation of lye: Take 9500ml of warm water at 55°C, 19g of solid sodium carbonate, and 19g of solid sodium hydroxide to make lye and keep the temperature at 55°C.

[0055] B、 Sprinkling of konjac fine powder: constant temperature lye (55°C), weigh 240 grams of first-grade konjac fine powder (national standard GB / T18104-2000) and evenly sprinkle it on the stirred lye, and the stirring speed is 160 rpm.

[0056] C、 Stirring reaction: After the konjac powder is sprinkled, continue to stir at 160 rpm for 13 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com