Method for preparing copper hydroxide phosphate micro-crystals with different shapes

A copper phosphate, basic technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

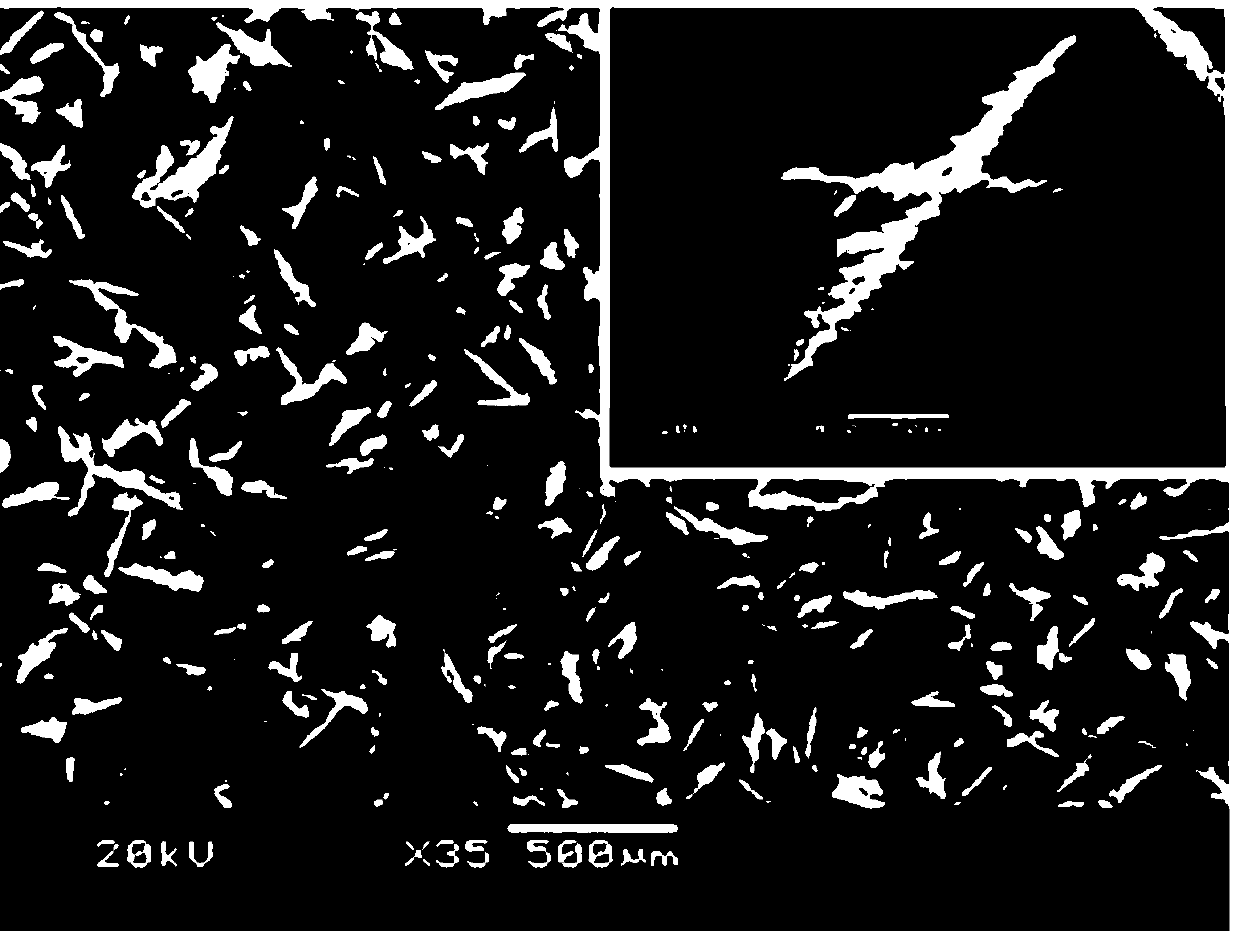

[0035] Slowly add the 0.3 mol / L copper acetate alcohol-water mixed solution dropwise into the 0.3 mol / L diammonium hydrogen phosphate alcohol-water mixed solution. The alcohol-water mixed solution is prepared by ethanol and water in a volume ratio of 1:2, copper acetate / diammonium hydrogen phosphate in a molar ratio of 2:1, and stirred and reacted at a stirring speed of 70 rpm for 20 minutes. The obtained mixed solution was subjected to hydrothermal reaction, the hydrothermal reaction temperature was 180° C., and the hydrothermal reaction time was 24 hours. After the hydrothermal reaction, cool down to room temperature naturally, filter and wash the product obtained by the reaction, put it in an oven, and dry it at 40 °C for 4 hours to obtain a basic copper phosphate microcrystalline material (see figure 1 Middle A and figure 2 ). The prepared basic copper phosphate microcrystalline material was used as a photocatalyst (1.5g / L) to degrade 20mg / L methyl orange solution. Be...

Embodiment 2

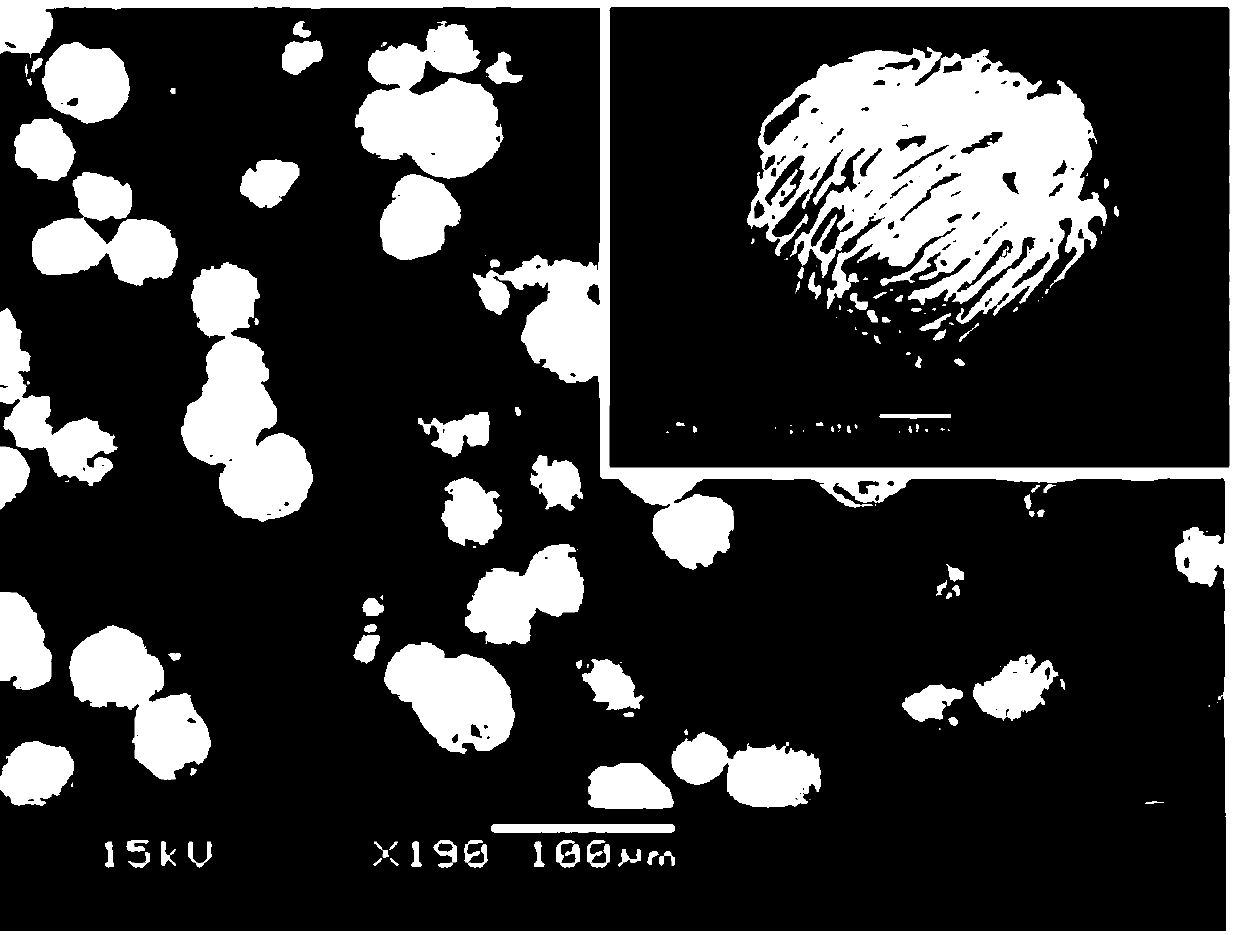

[0037]Slowly add the 0.5 mol / L copper acetate alcohol-water mixed solution dropwise to the 0.5 mol / L diammonium hydrogen phosphate alcohol-water mixed solution. The mixed solution of alcohol and water is prepared by ethylene glycol and water according to the volume ratio of 1:1, and the molar ratio of copper acetate / diammonium hydrogen phosphate is 2:1, and the reaction is stirred and reacted at a stirring speed of 70 rpm for 20 minutes. The obtained mixed solution was subjected to hydrothermal reaction, the hydrothermal reaction temperature was 180° C., and the hydrothermal reaction time was 24 hours. After the hydrothermal reaction, cool down to room temperature naturally, filter and wash the product obtained by the reaction, put it in an oven, and dry it at 40 °C for 4 hours to obtain a basic copper phosphate microcrystalline material (see figure 1 Medium B and image 3 ). The prepared basic copper phosphate microcrystalline material was used as a photocatalyst (1.5g / L) ...

Embodiment 3

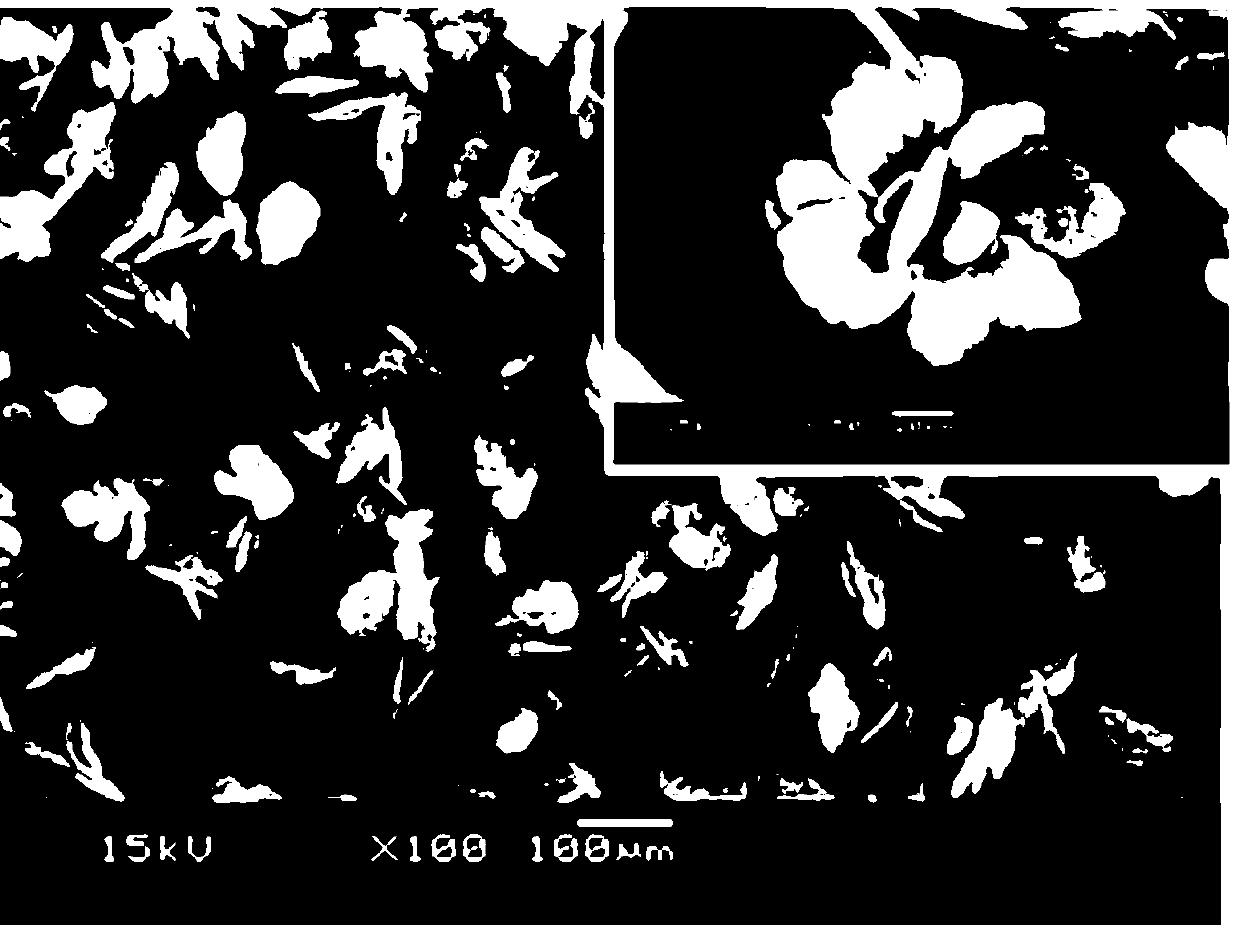

[0039] Slowly add the 0.5 mol / L copper acetate alcohol-water mixed solution dropwise to the 0.5 mol / L diammonium hydrogen phosphate alcohol-water mixed solution. The alcohol-water mixed solution is prepared by ethylene glycol and water in a volume ratio of 1:2, copper acetate / diammonium hydrogen phosphate in a molar ratio of 2:1, and stirred and reacted at a stirring speed of 70 rpm for 20 minutes. The obtained mixed solution was subjected to hydrothermal reaction, the hydrothermal reaction temperature was 180° C., and the hydrothermal reaction time was 24 hours. After the hydrothermal reaction, cool down to room temperature naturally, filter and wash the product obtained by the reaction, put it in an oven, and dry it at 40 °C for 4 hours to obtain a basic copper phosphate microcrystalline material (see figure 1 Medium C and Figure 4 ). The prepared basic copper phosphate microcrystalline material was used as a photocatalyst (1.5g / L) to degrade 20mg / L methyl orange solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com