Biodegradable blend and preparation method and application thereof

A biodegradable and blended technology, applied in the direction of conjugated rayon, conjugated synthetic polymer rayon, chemical characteristics of fibers, etc., can solve the problem of low elongation, poor mechanical properties, product application limitations, etc. problems, to achieve the effect of good compatibility, good mechanical properties, and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Weigh 80 parts by weight of cornstarch and 5 parts by weight of α-amylase and stir and mix them in a high-speed mixer for 10 minutes, leave to stand for 10 minutes to prepare dextrin, stir and mix the prepared dextrin with 15 parts by weight of glycerin at a low speed and then place in a dense The thermoplastic dextrin was prepared by kneading in a mill for 5 minutes.

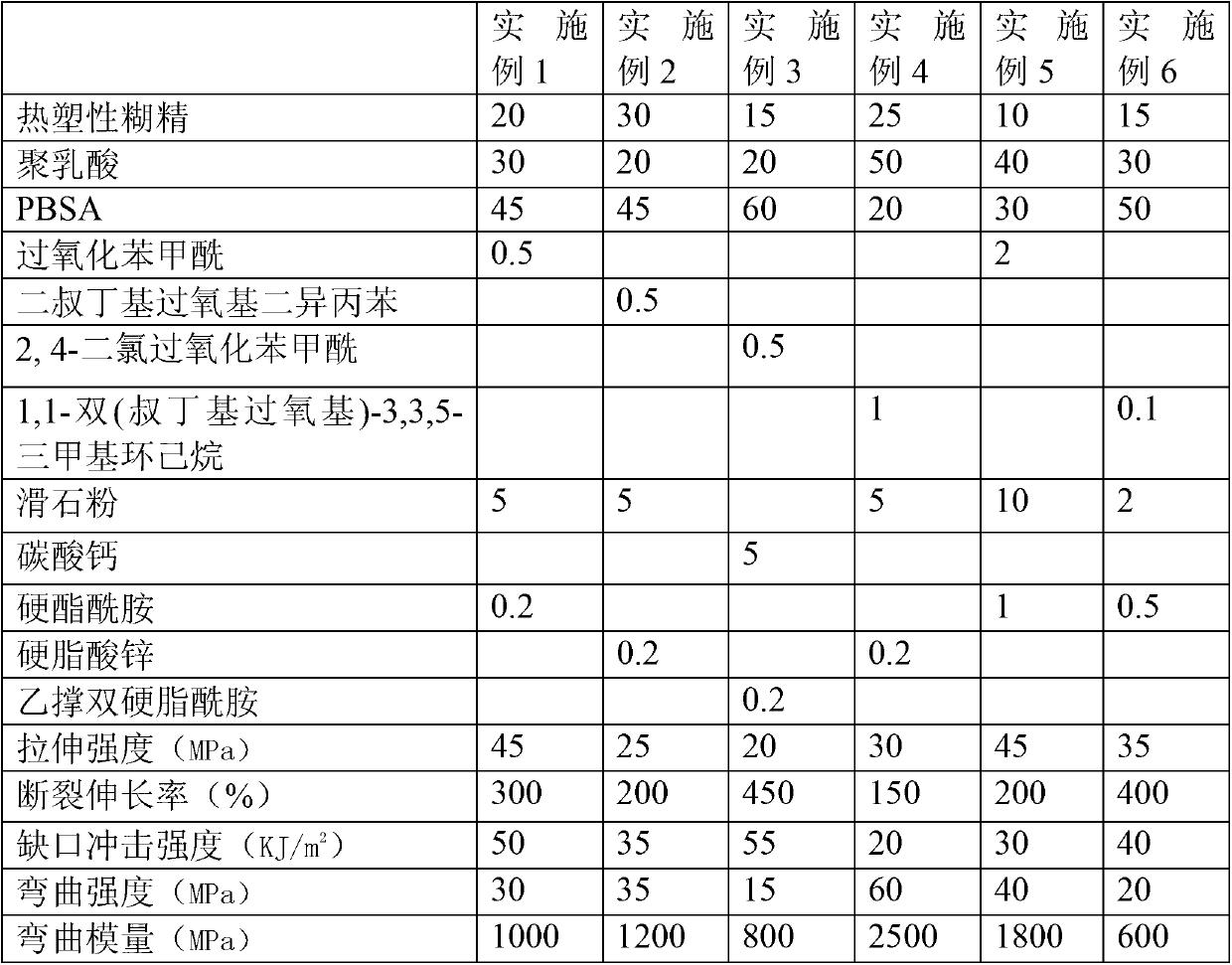

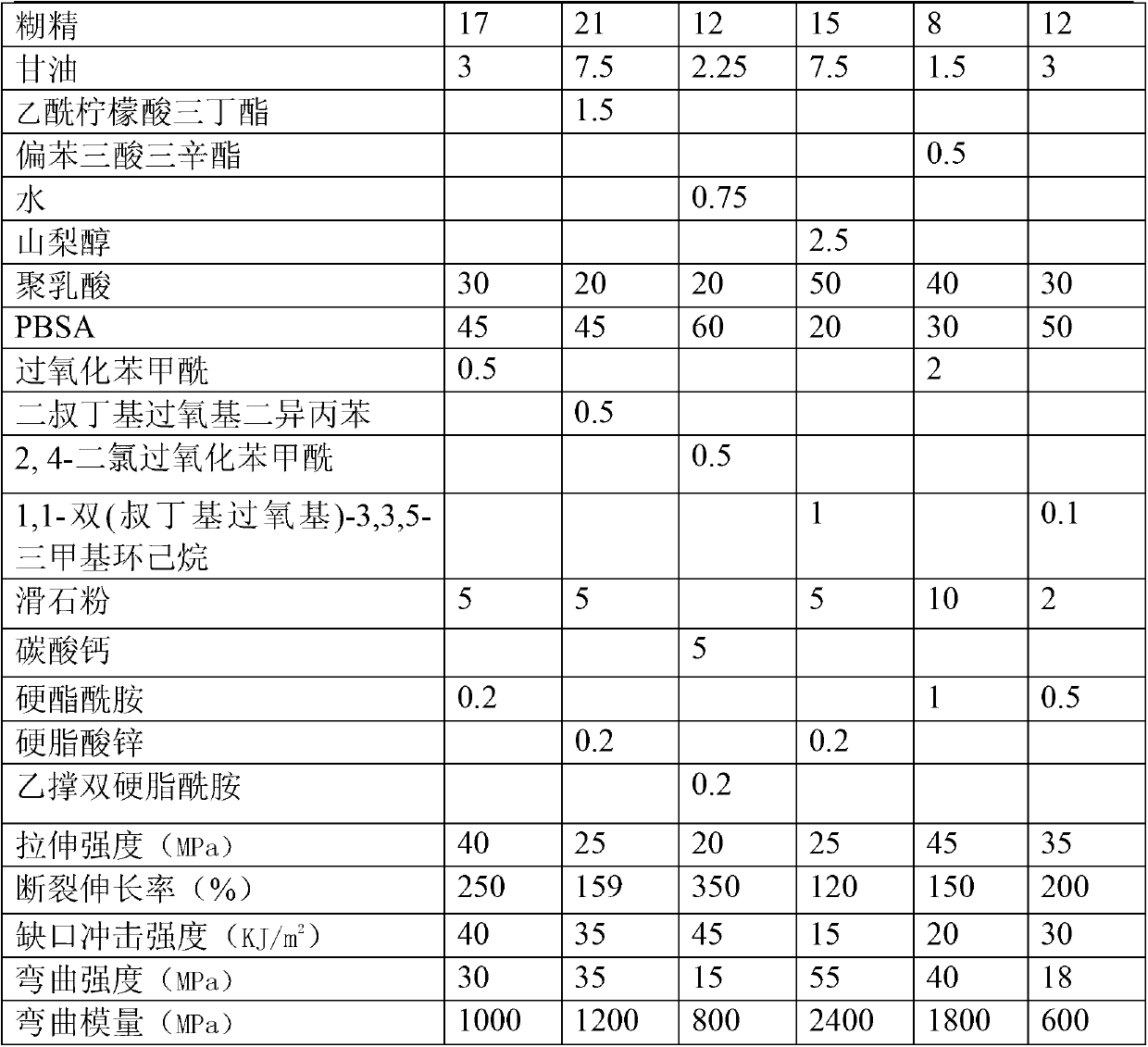

[0064] Get thermoplastic dextrin, polylactic acid, PBSA and other materials to join in the blender mechanical blending according to the weight portion shown in Table 1, then join the material after mixing in the twin-screw extruder extruding granulation, obtain Biodegradable blend. The tensile strength, elongation at break, notched impact strength, flexural strength and flexural modulus of the biodegradable blends were tested, and the test results are listed in Table 1.

Embodiment 2

[0066] Weigh 60 parts by weight of cornstarch and 10 parts by weight of beta-amylase and mix them in a high-speed mixer for 10 minutes, leave to stand for 10 minutes to prepare dextrin, and prepare the resulting dextrin with 25 parts by weight of glycerol and 5 parts by weight of acetylcitric acid The tributyl ester was stirred and mixed uniformly at a low speed, and then kneaded in an internal mixer for 8 minutes to prepare thermoplastic dextrin.

[0067] Get thermoplastic dextrin, polylactic acid, PBSA and other materials to join in the blender mechanical blending according to the weight portion shown in Table 1, then join the material after mixing in the twin-screw extruder extruding granulation, obtain Biodegradable blend. The tensile strength, elongation at break, notched impact strength, flexural strength and flexural modulus of the biodegradable blends were tested, and the test results are listed in Table 1.

Embodiment 3

[0069] Weigh 78 parts by weight of cornstarch and 2 parts by weight of α-amylase, stir and mix in a high-speed mixer for 10 minutes, leave to stand for 10 minutes to prepare dextrin, and stir the prepared dextrin with 15 parts by weight of glycerin and 5 parts by weight of water at a low speed After mixing evenly, it is plasticized in a single-screw extruder to obtain thermoplastic dextrin.

[0070] Get thermoplastic dextrin, polylactic acid, PBSA and other materials to join in the blender mechanical blending according to the weight portion shown in Table 1, then join the material after mixing in the twin-screw extruder extruding granulation, obtain Biodegradable blend. The tensile strength, elongation at break, notched impact strength, flexural strength and flexural modulus of the biodegradable blends were tested, and the test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com