Stable peroxyacetic acid disinfectant

A peracetic acid disinfectant and a stable technology, applied in the directions of disinfectants, biocides, animal repellents, etc., can solve the problems of affecting the application of peracetic acid disinfectants, reducing disinfectant stabilizers, difficult to control stability, and the like, Achieve excellent hydrophilicity, obvious stabilization effect, and wide compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

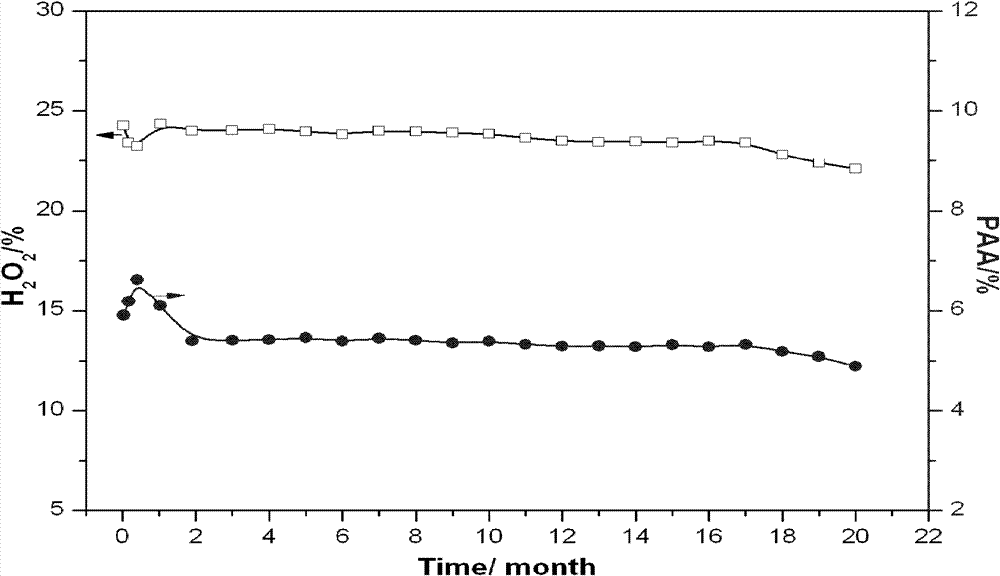

[0019] The formula of peracetic acid disinfectant is as follows: hydrogen peroxide: 26% glacial acetic acid: 15% sulfuric acid: 2% sodium lauryl sulfate: 0.05% hydrolyzed maleic anhydride copolymer and ethylenediaminetetramethylphosphoric acid compound (1:1): The balance of 0.05% is water.

[0020] Hydrolyzed maleic anhydride copolymer is prepared in the following manner among the embodiment 1: take by weighing 4.96g maleic anhydride and 4.36g vinyl acetate, add in the mixed solvent three-necked flask that is equipped with to 40mL butyl acetate and n-heptane, After the maleic anhydride was dissolved, 0.15 g of azobisisobutyrocyanide was added, and after it was completely dissolved, it was placed in a water bath at 80°C for 6 hours of reaction. After the reaction was completed, it was taken out by suction and dried for later use. Weigh 2 g of dried maleic anhydride-vinyl acetate copolymer, hydrolyze it with 1 mol / L sodium hydroxide aqueous solution at 40°C, precipitate with me...

Embodiment 2

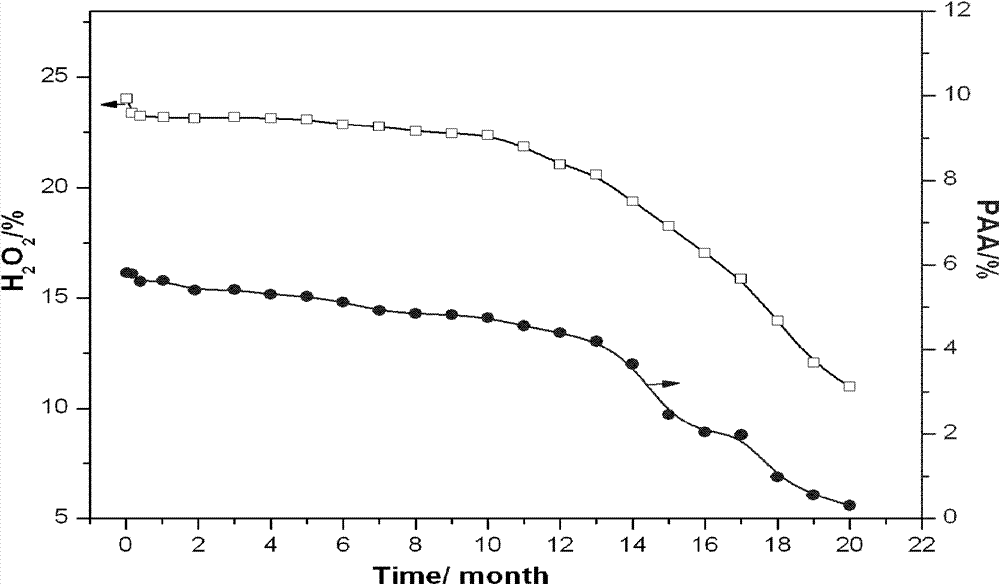

[0030] The disinfectant formula is as follows: hydrogen peroxide: 26% glacial acetic acid: 15% sulfuric acid: 2% sodium lauryl sulfate: 0.05% hydrolyzed maleic anhydride copolymer and ethylenediaminetetramethylphosphoric acid compound (1: 3): The 0.05% balance is water, and the preparation process is the same as in Example 1. The contents of peracetic acid and hydrogen peroxide are listed in Table 2 after 30 days of equilibrium.

Embodiment 3

[0032] Hydrogen peroxide: 26% Glacial acetic acid: 15% Sulfuric acid: 2% Sodium lauryl sulfate: 0.05% Hydrolyzed maleic anhydride copolymer and ethylenediaminetetramethylphosphoric acid compound (2:1): 0.05% The balance is water, and the preparation process is the same as in Example 1. The contents of peracetic acid and hydrogen peroxide are listed in Table 2 after 30 days of equilibrium.

[0033] From the results of Example 1 to Example 3 and Table 2, it can be seen that when the ratio of hydrolyzed maleic anhydride copolymer and ethylenediaminetetramethylphosphoric acid was changed from 1: 3 to 2: 1, hydrogen peroxide and peroxygen The content of acetic acid experienced a process of increasing first and then decreasing, and reached the highest when the ratio of the two was 1:1, which were 15% and 12%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com