Color paste and preparation technology thereof

A production process and technology of color paste, applied in the direction of pigment paste, etc., can solve the problems of poor stability, easy fading, poor compatibility, etc., and achieve the effect of good stability and compatibility, and wide compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

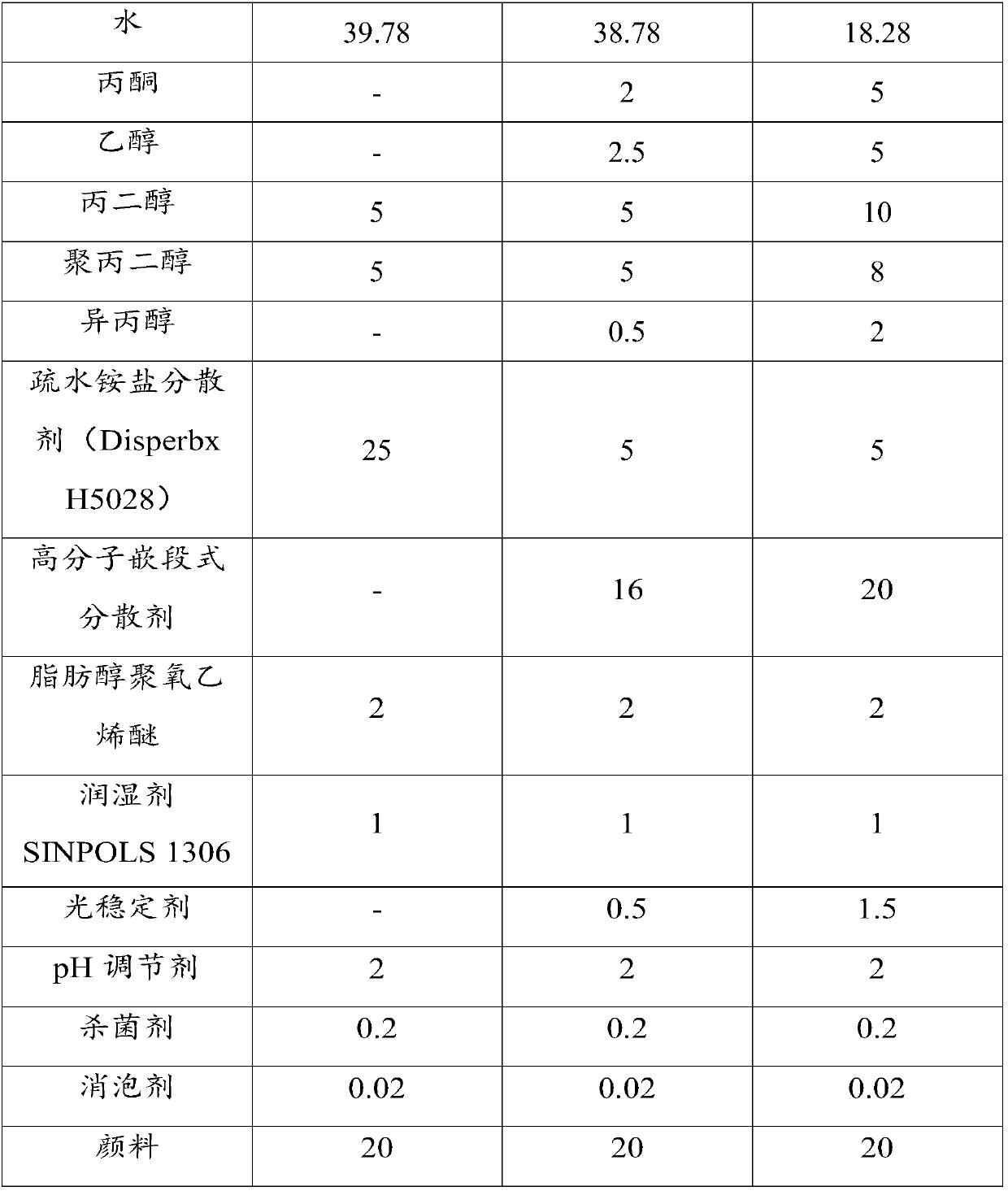

[0028] A color paste provided in this embodiment comprises the following raw materials in parts by weight: 38.78 parts of water, 15 parts of solvent, 24 parts of surfactant, 0.5 part of light stabilizer, 2 parts of pH regulator, and 0.2 part of bactericide , 0.02 parts of defoamer and 20 parts of pigments.

[0029] Wherein, the solvent includes 2 parts of acetone, 2.5 parts of ethanol, 5 parts of propylene glycol, 5 parts of polypropylene glycol and 0.5 part of isopropyl alcohol, and the surfactant includes 1 part of wetting agent (SINPOLS1306), fatty alcohol polyoxyethylene ether (980 ) 2 parts, hydrophobic ammonium salt dispersant (Disperbx H5028) 5 parts, polymer block dispersant 16 parts.

no. 2 example

[0031] A color paste provided in this embodiment comprises the following raw materials in parts by weight: 18.28 parts of water, 30 parts of solvent, 28 parts of surfactant, 1.5 parts of light stabilizer, 2 parts of pH regulator, and 0.2 part of bactericide , 0.02 parts of defoamer and 20 parts of pigments.

[0032] Wherein, the solvent includes 5 parts of acetone, 5 parts of ethanol, 10 parts of propylene glycol, 8 parts of polypropylene glycol and 2 parts of isopropyl alcohol, and the surfactant includes 1 part of wetting agent (SINPOLS 1306), fatty alcohol polyoxyethylene ether ( 980) 2 parts, hydrophobic ammonium salt dispersant (Disperbx H5028) 5 parts, polymer block dispersant 20 parts.

no. 3 example

[0034] The manufacturing process of a color paste provided in this embodiment comprises the following steps: mixing water with a dispersant and a wetting agent for 10 minutes at a speed of 600 r / min, and then mixing with a pigment for 1 hour at a speed of 2600 r / min to obtain the first A mixed solution.

[0035] The solvent and the light stabilizer were mixed according to the ratio of 99:1 WT% for 20 minutes at a rotation speed of 400 r / min to obtain a second mixed solution. The first mixed solution was mixed with the second mixed solution for 30 minutes at a speed of 400 r / min to obtain a third mixed solution, which was then mixed with a pH regulator, bactericide and defoamer for 1 hour at a speed of 200 r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com