Acrylic acid terpolymer dispersing agent and preparation method and applications thereof

A terpolymer, dispersant technology, applied in chemical instruments and methods, chemical/physical processes, transportation and packaging, etc., can solve the problem of failing to effectively bind the sterically hindered segment of the resin compatible chain, and achieve storage. Good stability, easy product availability and excellent blooming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

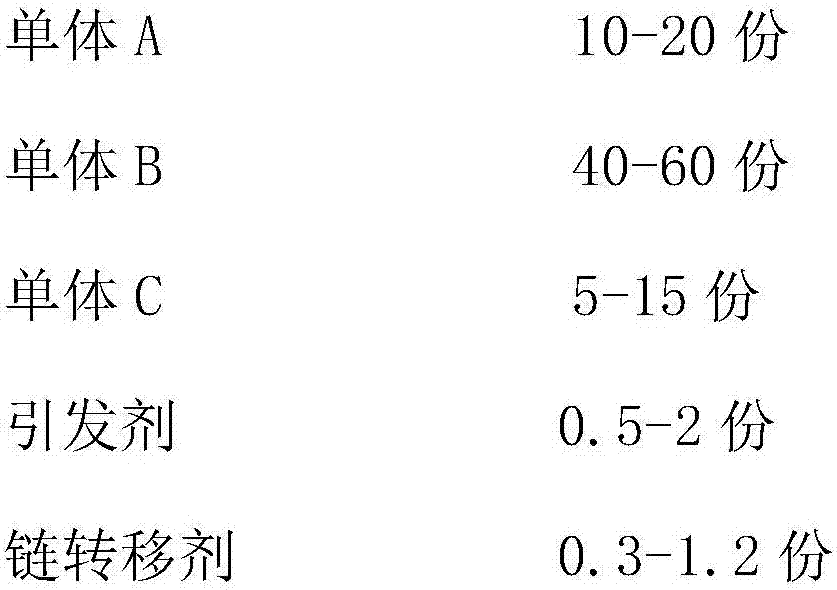

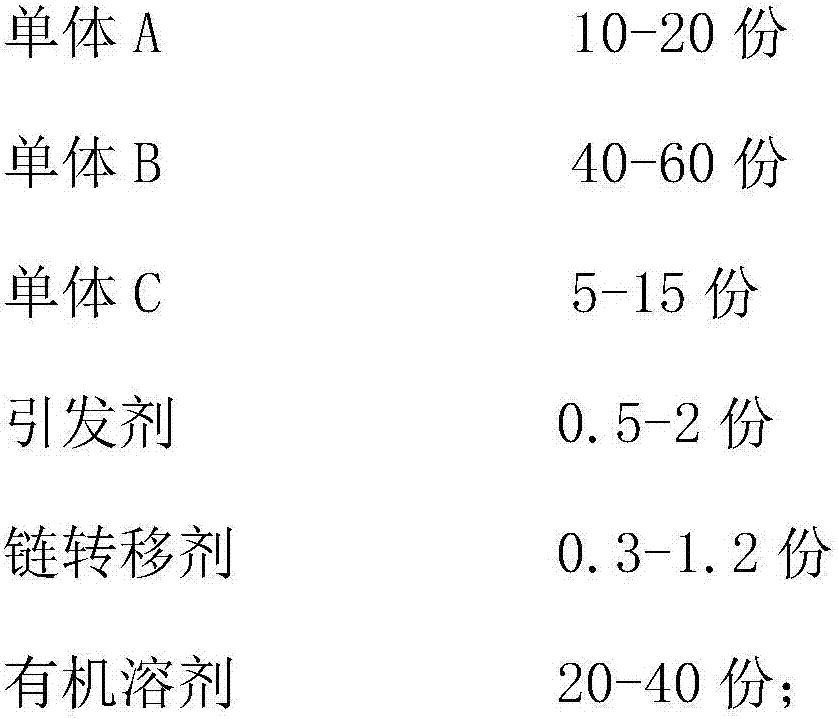

[0039] The preparation method of this acrylic acid terpolymer dispersant comprises the steps:

[0040] (1) Dissolving an initiator accounting for 35 wt% of the total amount of the initiator in an organic solvent accounting for 35 wt% of the total amount of the organic solvent, and preheating to 60-90° C. to obtain the first solution.

[0041] (2) monomer A, monomer B, monomer C, chain transfer agent and the initiator accounting for 55wt% of the total amount of the initiator are dissolved in an organic solvent accounting for 55wt% of the total amount of the organic solvent to obtain the second solution.

[0042] (3) The second solution obtained in step (2) is added to the first solution at a uniform speed within 2-4 hours; after adding, keep warm for 4-6 hours, add the remaining initiator and organic solvent, and heat up to 70 -100°C, continue to keep warm for 4-24 hours to obtain a dispersant solution, add a precipitant 5-20 times the volume of the dispersant solution to preci...

Embodiment 1

[0045] (1) Dissolve 2,2'-azobisisobutyronitrile (35wt%) of 2,2'-azobisisobutyronitrile total amount (0.5 parts by weight) in 35wt% of butyl acetate total amount (20 parts by weight) In butyl acetate, preheat to 60°C to obtain the first solution.

[0046] (2) 10 parts by weight of myristyl methacrylate, 40 parts by weight of methyl methacrylate, 5 parts by weight of methacrylamide, 0.3 parts by weight of octadecyl mercaptan and 2,2'-azo 55wt% of the total amount of diisobutyronitrile (0.5 parts by weight) of 2,2'-azobisisobutyronitrile was dissolved in 55wt% of butyl acetate (20 parts by weight) of the total amount of butyl acetate to obtain a second solution.

[0047](3) Add the second solution obtained in step (2) to the first solution at a uniform speed within 2 hours; after the addition, keep warm for 4 hours, and add the remaining 2,2'-azobisisobutyronitrile and acetic acid For butyl ester, heat up to 70°C, keep warm for 24 hours to obtain a dispersant solution, add n-hex...

Embodiment 2

[0049] (1) be dissolved in the propylene glycol butyl ether acetate accounting for propylene glycol butyl ether acetate total amount (30 weight parts) 35wt% benzoyl peroxide total amount (1 weight part) 35wt% benzoyl peroxide, Preheat to 70°C to obtain the first solution.

[0050] (2) 15 parts by weight of cetyl acrylate, 50 parts by weight of ethyl acrylate, 10 parts by weight of N-methylol acrylamide, 0.8 parts by weight of dodecyl mercaptan and the total amount of benzoyl peroxide (1 55 wt% of benzoyl peroxide is dissolved in 55 wt% of propylene glycol butyl ether acetate total amount (30 parts by weight) of propylene glycol butyl ether acetate to obtain a second solution.

[0051] (3) The second solution obtained in step (2) is added to the first solution at a uniform speed within 4 hours; after adding, keep warm for 5 hours, add the remaining benzoyl peroxide and propylene glycol butyl ether acetate, and heat up Keep warm at 90°C for 16 hours to obtain a dispersant solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com