A metal antirust agent containing modified nano potassium feldspar powder

A technology of nano-potassium feldspar powder and metal anti-rust agent, which is applied in the field of metal anti-rust, can solve the problems of inability to form anti-rust protection, and achieve good gas-phase anti-rust effect, good gas-phase anti-rust effect, and excellent contact anti-rust performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

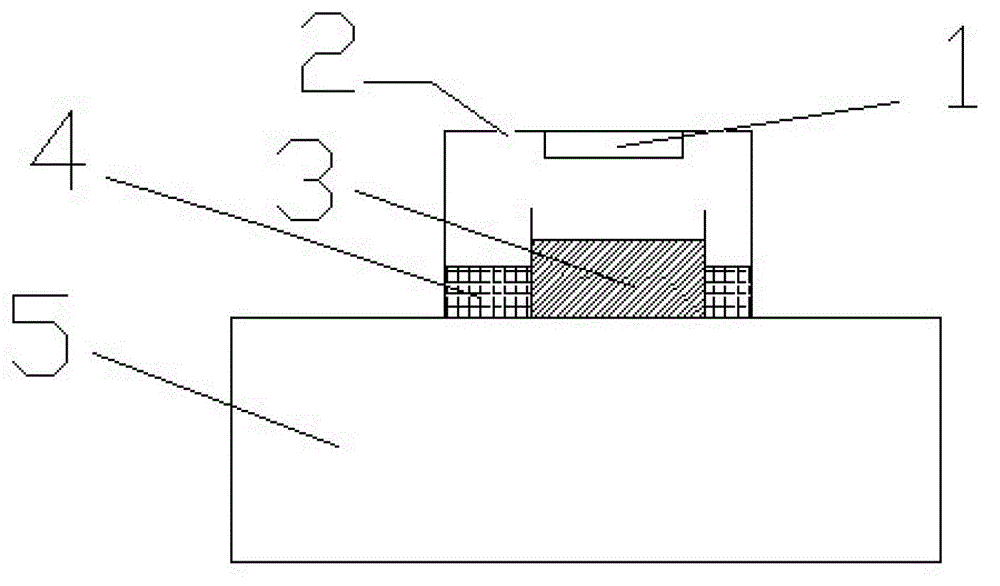

Image

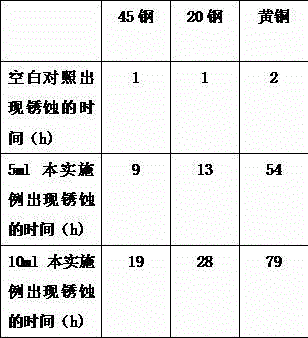

Examples

Embodiment Construction

[0018] A metal antirust agent containing modified nano-potassium feldspar powder, which is made from the raw materials of the following parts by weight (kg):

[0019] Castor oil 100, ferrocene 1.3, polyisobutene 2.8, sodium benzoate 1, sodium sebacate 1.9, 2-methylimidazole 0.7, ethanolamine 1.7, 8-hydroxyquinoline 0.9, N-phenyl-2-naphthylamine 1.2 , glycerol triacetate 0.7, sodium lauryl sulfate 1.2, film-forming resin 6.7, modified nano-potassium feldspar powder 0.7;

[0020] The film-forming resin is prepared from the following raw materials in parts by weight: rosin 6.8, urea 2.4, zinc powder 2, dimethyl silicone oil 2, liquefied paraffin 10, 3-aminopropyltrimethoxysilane 3.4, acetylcitric acid Tris (2-ethylhexyl) ester 6.3, epoxy linseed oil 11.4, xylene 12.5, polyvinyl alcohol 7;

[0021] The preparation method of the modified nano-potassium feldspar powder is as follows: the potassium feldspar is calcined at 650°C for 6 hours, ground into powder, soaked in 10% hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com