A kind of antirust agent containing modified coke gemstone powder

A technology for modifying coke and gemstone powder, which is applied in the field of metal rust prevention, can solve the problems of difficult rust prevention by oiling, narrow and fine blind holes, etc., and achieves the effects of simple production process, convenient use and excellent rust prevention performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

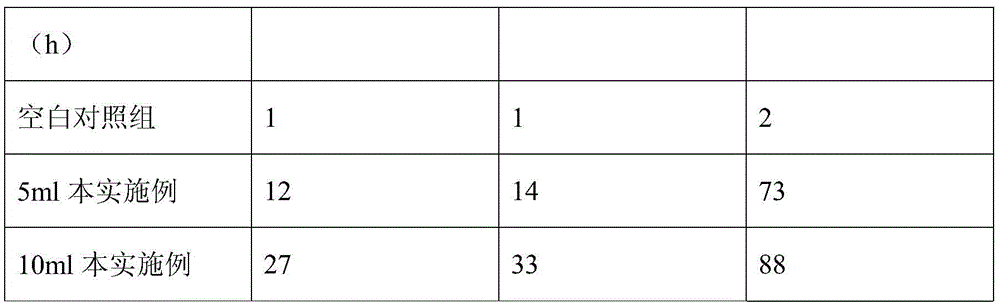

[0016] A kind of antirust agent containing modified coke gem powder, made from the following raw materials in parts by weight: 100 parts of castor oil, 8 parts of barium petroleum sulfonate, 8 parts of calcium stearate, 2 parts of ferrocene, 2 parts of capric acid 2 parts, 2 parts of dibutyl succinate, 0.8 parts of methyl benzotriazole, 2 parts of sodium zinc dihydrogen phosphate, 0.9 parts of 2-aminoethyl heptadecenyl imidazoline, 1.3 parts of triethanolamine, urotropine 2 parts, 2 parts of zinc dialkyl dithiophosphate, 3 parts of acetyl triethyl citrate, 6 parts of zinc sulfate, 2 parts of lead nonanoate, 9 parts of sodium citrate, 6 parts of morpholine, dodecylbenzene 3 parts of sodium sulfonate, 6 parts of film-forming resin, 2 parts of modified coke gem powder;

[0017] The film-forming resin is prepared from the following raw materials in parts by weight: 6 parts of rosin, 3 parts of urea, 2 parts of zinc powder, 4 parts of simethicone, 16 parts of liquefied paraffin, 3-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com