Chlorine-doped graphene and preparation method and application thereof

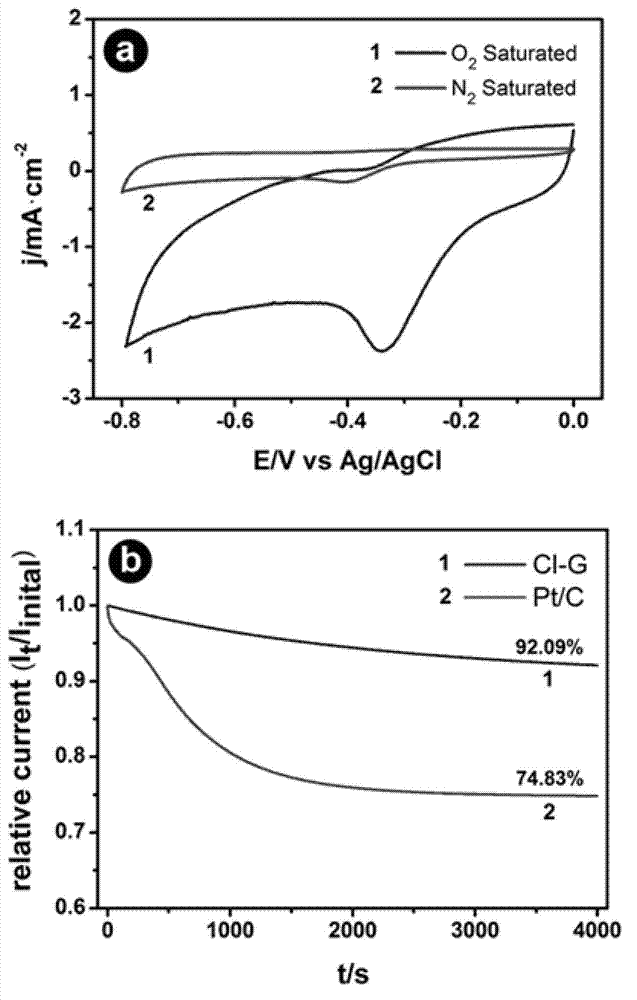

A graphene and chlorine doping technology, applied in chemical instruments and methods, electrical components, circuits, etc., can solve the problems of high cost of noble metal catalysts, lack of resources, etc., and achieve the improvement of oxygen reduction catalytic activity and stability, and good catalytic activity , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 10ml of carbon tetrachloride and add it to a 250ml three-necked flask, reflux at 130°C for 30 minutes, then take 1g of magnesium strips and ignite them in the air and quickly put them into the three-necked flask, a large amount of black matter will be produced instantaneously, filter , to obtain a filter cake.

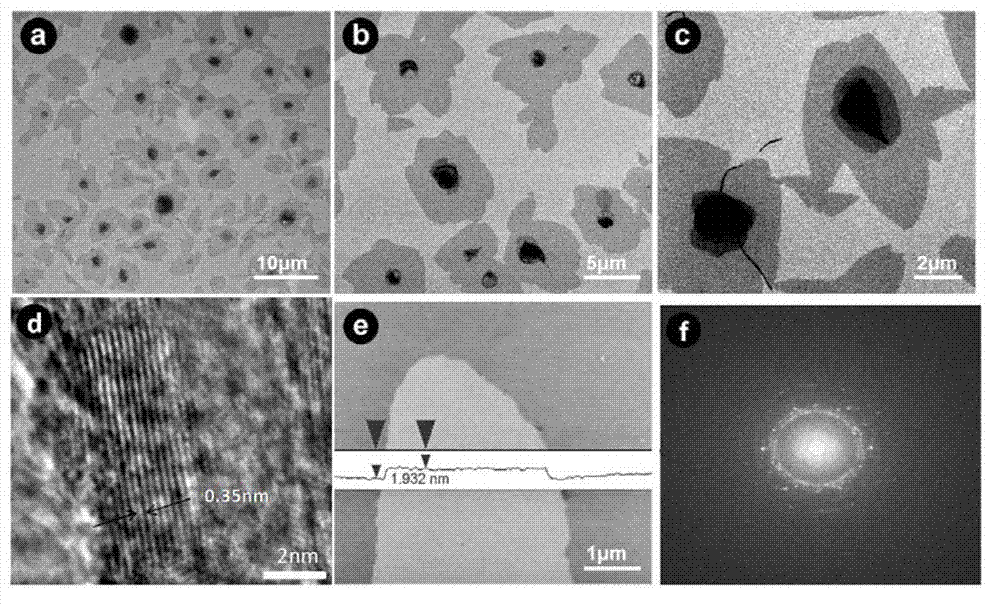

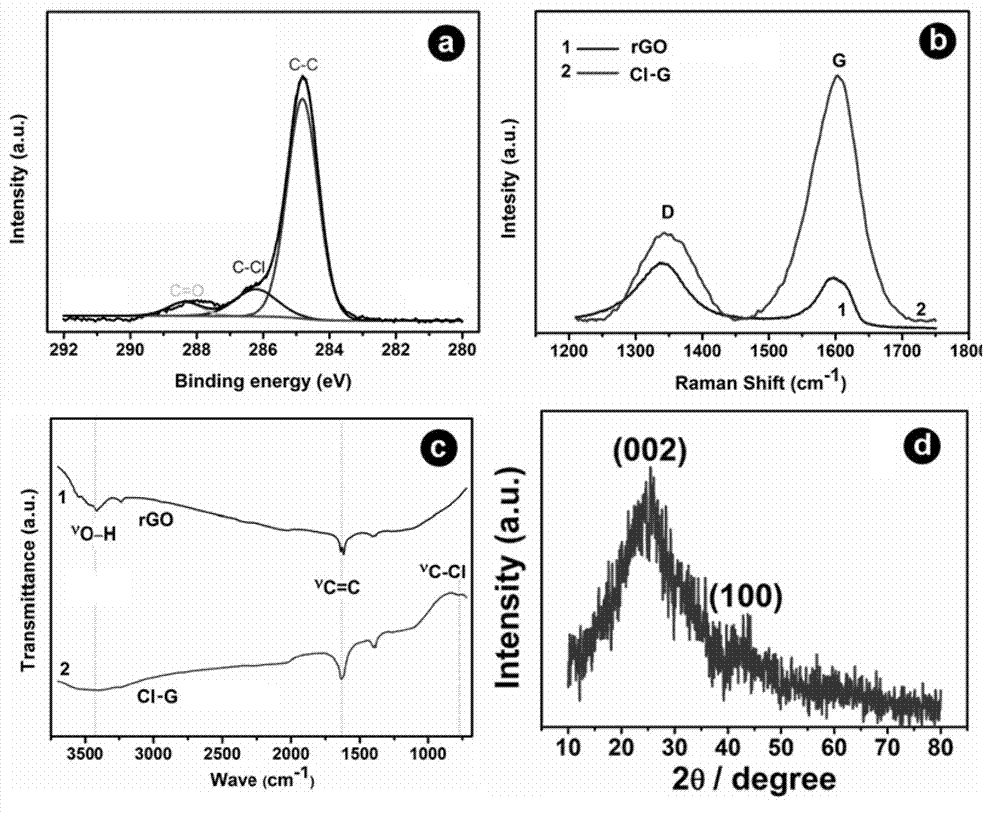

[0027] The resulting filter cake was rinsed with absolute ethanol to remove excess carbon tetrachloride, and centrifuged (7000 rpm, 5 min) to obtain a black solid substance, that is, precipitate a. Immerse the precipitate a in aqueous hydrochloric acid solution with a mass concentration of 15%, fully stir at 25°C for 30 minutes, and centrifuge (7000rpm, 5min). Take the precipitate b and wash it twice with pure water and absolute ethanol, and then centrifuge again (7000rpm , 5min), to obtain the precipitate c, freeze-dry the precipitate c at -80℃ for 10h, and obtain 50mg of chlorine-doped graphene material, the area of chlorine-doped graphene sheet is 10~4...

Embodiment 2

[0029] Take 10ml of chloroform and add it to a 250ml three-necked flask, reflux at 80°C for 30 minutes to obtain a chloroform reflux liquid, then take 1g of magnesium strips and ignite them in the air and quickly put them into the three-necked flask to generate instantaneous A large amount of black matter was filtered to obtain a filter cake.

[0030]Wash the resulting filter cake with absolute ethanol to remove excess chloroform, and centrifuge (7000rpm, 5min) to obtain precipitate a. Soak the above precipitate a in aqueous hydrochloric acid solution with a mass concentration of 15%, fully stir at 25°C for 30 minutes, centrifuge (7000rpm, 5min), take the precipitate b, wash it twice with pure water and absolute ethanol, and centrifuge again ( 7000rpm, 5min), obtained precipitate c, freeze-dried the precipitate c at -80°C for 10h, obtained 30mg of chlorine-doped graphene material, and the area of chlorine-doped graphene sheet was 10-40μm 2 .

Embodiment 3

[0032] Take 20ml of carbon tetrachloride and add it to a 250ml three-necked flask, reflux at 120°C for 20 minutes to obtain a carbon tetrachloride reflux liquid, then take 1g of magnesium strips and ignite them in the air and quickly put them into the three-necked flask. A large amount of black matter is produced instantaneously, and filtered to obtain a filter cake.

[0033] Wash the resulting filter cake with absolute ethanol to remove excess carbon tetrachloride, and centrifuge (7000rpm, 5min) to obtain precipitate a. Add the above precipitate a into the hydrochloric acid aqueous solution with a mass concentration of 15%, fully stir at 25°C for 30 minutes, centrifuge (7000rpm, 5min), take the precipitate b, wash them twice with pure water and absolute ethanol, and centrifuge again (7000rpm , 5min), to obtain the precipitate c, freeze-dry the precipitate c at 80℃ for 10h, and obtain 40mg of chlorine-doped graphene material, the area of chlorine-doped graphene sheet is 10~4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com