Cation-modified emulsified asphalt for bonding layer and preparation method of cation-modified emulsified asphalt

A cationic emulsifier, emulsified asphalt technology, used in building components, building insulation materials, construction and other directions, can solve the problems of insufficient high-performance emulsified asphalt, difficult emulsification of asphalt, construction impact, etc. Performance improvement, good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

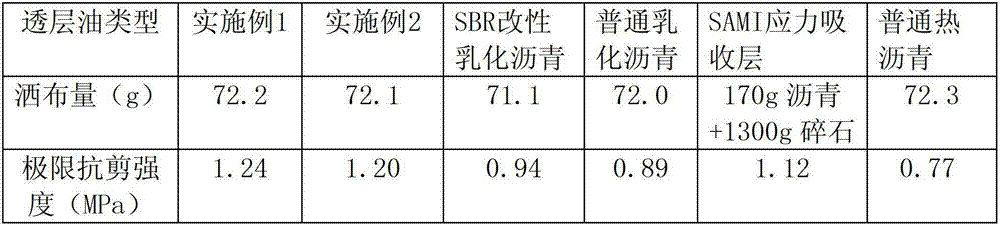

Examples

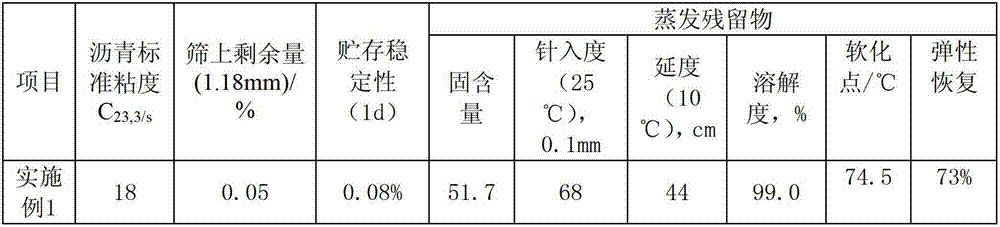

Embodiment 1

[0034] Embodiment 1 is illustrated by taking the preparation of 500g cationic modified emulsified asphalt for adhesive layer as an example:

[0035] First weigh 230g SK90 road petroleum asphalt, then add 9g SBS modifier (linear styrene-butadiene-styrene Block copolymer, the block ratio is 10 / 90-20 / 80, the molecular weight is 80,000-90,000), the asphalt is heated to 160-170°C after mechanical stirring for 40 minutes, and then the modified equipment (shearing machine) Medium shearing for 30 minutes, the speed of the shearing machine is 4000r / min, then cooling to 140-150°C, after cooling, add 0.5g of crosslinking agent (provided by Jinan Zhongjiao Road and Bridge Engineering Co., Ltd., model LZ-STAB-03) , continue shearing for 10 minutes to prepare modified asphalt, and keep the prepared modified asphalt at 140-150° C. for further use. Weigh 245g of water, 7.5g of cationic emulsifier (the cationic emulsifier is the cationic emulsifier DF-62 produced by Medworth Vacc), 1g of calc...

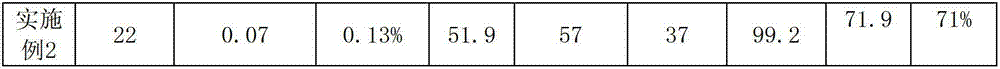

Embodiment 2

[0036] Example 2 is illustrated by taking the preparation of 400g cationic modified emulsified asphalt for adhesive layer as an example

[0037] First weigh 190g of Esso No. 70 road petroleum asphalt, and then add 7g of SBS modifier (linear styrene-butadiene produced by Shell Company) to the Esso No. 70 road petroleum asphalt in the hot melt state (140-150°C). - Styrene block copolymer, block ratio is 10 / 90-20 / 80, molecular weight is 80,000-90,000), after mechanical stirring for 40 minutes, the asphalt is heated to 160-170°C, and then in the modification equipment (shear cutting machine) for 30 minutes, the shearing machine speed is 4000r / min, then cooled to 140 ~ 150 ° C, after cooling, add 0.4g crosslinking agent (provided by Jinan Zhongjiao Road and Bridge Engineering Co., Ltd., model LZ-STAB -03), continue shearing for 10 minutes to prepare modified asphalt, and keep the prepared modified asphalt at 140-150°C for use. Weigh 190g of water, 6g of cationic emulsifier (the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com