Preparation method of polyacrylate/nano ZnO composite leather finishing agent

A technology of polyacrylate and leather finishing agent, applied in coating, textile and papermaking, fiber processing and other directions, can solve the problems of sticky composite emulsion coating film and poor film stability, achieve stable polymerization process and overcome polymerization temperature High, improving the effect of hot sticking and cold brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

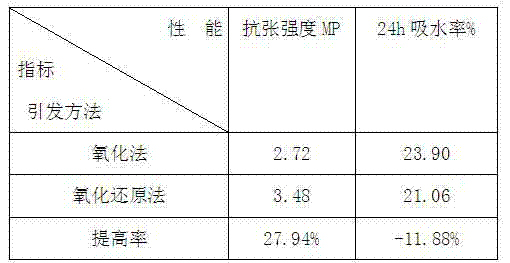

Embodiment 1

[0029] Step 1: Dissolve 0.3 parts by weight of emulsifier in 30 parts by weight of deionized water, adjust the pH value to 7 with ammonia water, then transfer the above solution into a dry three-necked flask, and keep it warm at 50°C for 20 minutes to form an emulsifier aqueous solution;

[0030] Step 2: Prepare 0.15 parts by weight of oxidizing agent, 0.03 parts by weight of reducing agent and 30 parts by weight of acrylate monomer, weigh 1 / 10 of the total amount of oxidizing agent and 1 / 10 of the total amount of reducing agent and dissolve them in 2 wt. 1 part of deionized water to form an aqueous solution of oxidizing agent and reducing agent, then add 1 / 6 of the total amount of acrylate monomers, the aqueous solution of oxidizing agent and reducing agent to the emulsifier aqueous solution in sequence, and keep warm at 60°C for 26 minutes;

[0031] Step 3: take 0.24 parts by weight of zinc acetate and dissolve it in 12 parts by weight of deionized water to form an aqueous s...

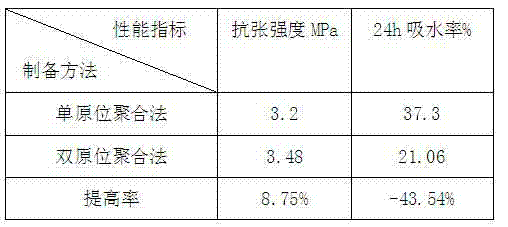

Embodiment 2

[0037] Step 1: Dissolve 0.5 parts by weight of emulsifier in 30 parts by weight of deionized water, adjust the pH value to 7 with ammonia water, then transfer the above solution into a dry three-necked flask, and keep it warm at 50°C for 20min to form Emulsifier aqueous solution;

[0038] Step 2: Prepare 0.2 parts by weight of oxidizing agent, 0.06 parts by weight of reducing agent and 30 parts by weight of acrylate monomer, weigh 1 / 10 of the total amount of oxidizing agent and 1 / 10 of the total amount of reducing agent and dissolve them in 2 parts by weight part of deionized water to form an aqueous solution of oxidizing agent and reducing agent, then add 1 / 6 of the total amount of acrylate monomers, the aqueous solution of oxidizing agent and reducing agent to the emulsifier aqueous solution in sequence, and keep warm at 60°C for 29 minutes;

[0039]Step 3: take 0.48 parts by weight of zinc acetate and dissolve it in 12 parts by weight of deionized water to form an aqueous s...

Embodiment 3

[0045] Step 1: Dissolve 0.7 parts by weight of emulsifier in 30 parts by weight of deionized water, adjust the pH value to 7 with ammonia water, then transfer the above solution into a dry three-necked flask, and keep it warm at 50°C for 20 minutes to form an emulsifier aqueous solution;

[0046] Step 2: Prepare 0.2 parts by weight of oxidizing agent, 0.09 parts by weight of reducing agent and 30 parts by weight of acrylate monomer, weigh 1 / 8 of the total amount of oxidizing agent and 1 / 8 of the total amount of reducing agent and dissolve them in 2 parts by weight part of deionized water to form an aqueous solution of oxidizing agent and reducing agent, and then add 1 / 4 of the total amount of acrylate monomers, the aqueous solution of oxidizing agent and reducing agent to the emulsifier aqueous solution in sequence, and keep warm at 65°C for 32 minutes;

[0047] Step 3: take 0.72 parts by weight of zinc acetate and dissolve it in 12 parts by weight of deionized water to form a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com