Composition for alkali-free chemical complex oil displacement and application thereof in tertiary oil recovery

A composite flooding and composition technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of high production cost, poor solubility, high Krafft point, etc., and achieve good long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

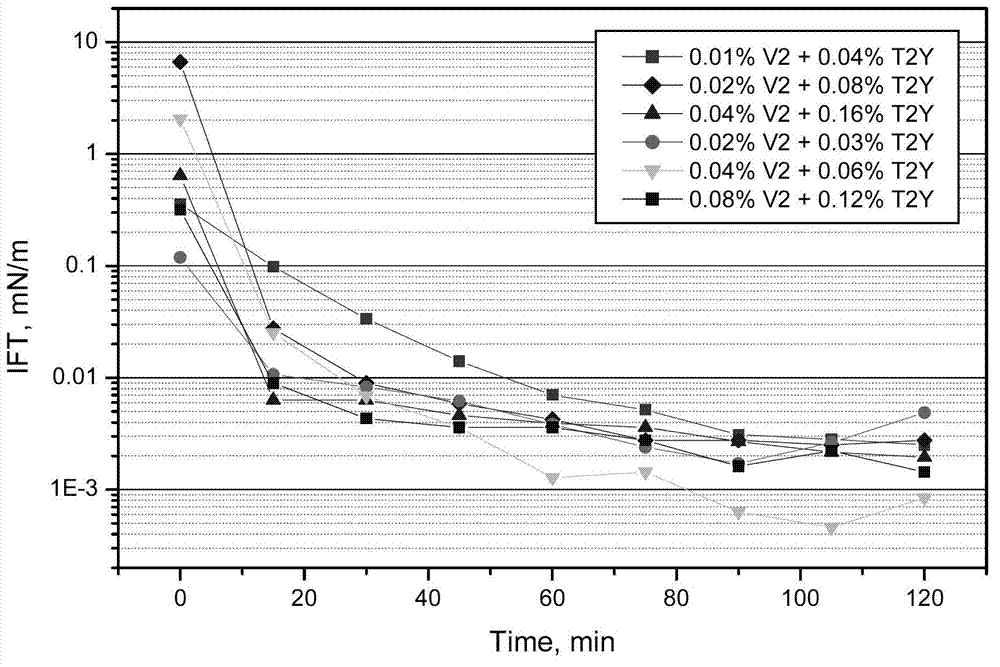

[0052] Reservoir 1 block 1 oil-water interfacial tension test

[0053] Use the produced water (formation water) of block 1 of the oil reservoir to prepare the composition for non-alkali chemical flooding with the mass concentration of composite surfactant being 0.05%, 0.10% and 0.20%, and the mass percentage concentration of polymer HPAM being 0.09%. , to measure the interfacial tension between it and the crude oil in block 1 of reservoir 1. Among them, the composite surfactant is erucamide propyl carboxybetaine (V2) and betaine (T2Y), and the weight ratio of the two is 20:80 and 40:60. The test results are shown in Table 1 and figure 1 shown.

[0054] Table 1 Oil-water interfacial tension table of the composition for alkali-free chemical flooding in reservoir 1 block 1 condition (HPAM0.09%)

[0055]

Embodiment 2

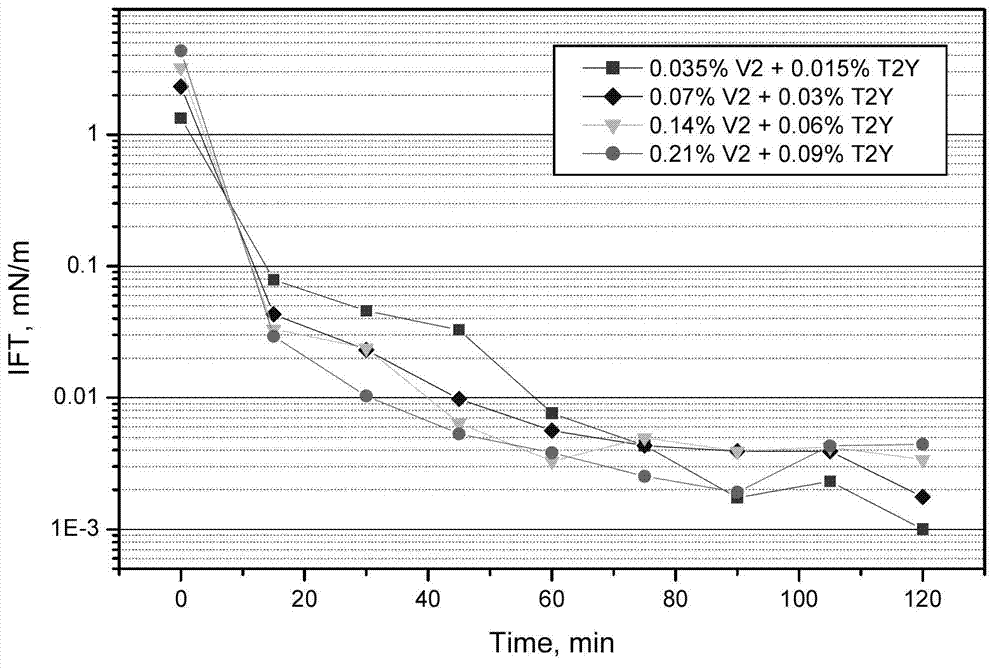

[0057] Reservoir 1 block 2 oil-water interfacial tension test

[0058] The produced water (formation water) of block 2 of reservoir 1 was used to prepare composite surfactants with mass percentage concentrations of 0.05%, 0.10%, 0.20%, and 0.30% respectively, and hydrophobic association polymers with mass percentage concentrations of 0.25% without The composition for alkali chemical flooding was used to measure the dynamic interfacial tension between it and the crude oil in block 1 of the reservoir. Wherein, the composite surfactant adopts erucamide propyl carboxy betaine (V2) and docosyl hydroxypropyl sulfobetaine (T2Y), and the weight ratio of the two is 70:30. The test results are shown in Table 2 and figure 2 shown.

[0059] Table 2 The oil-water interfacial tension table of the composition for alkali-free chemical flooding in block 2 of reservoir 1 (polymer 0.25%)

[0060]

Embodiment 3

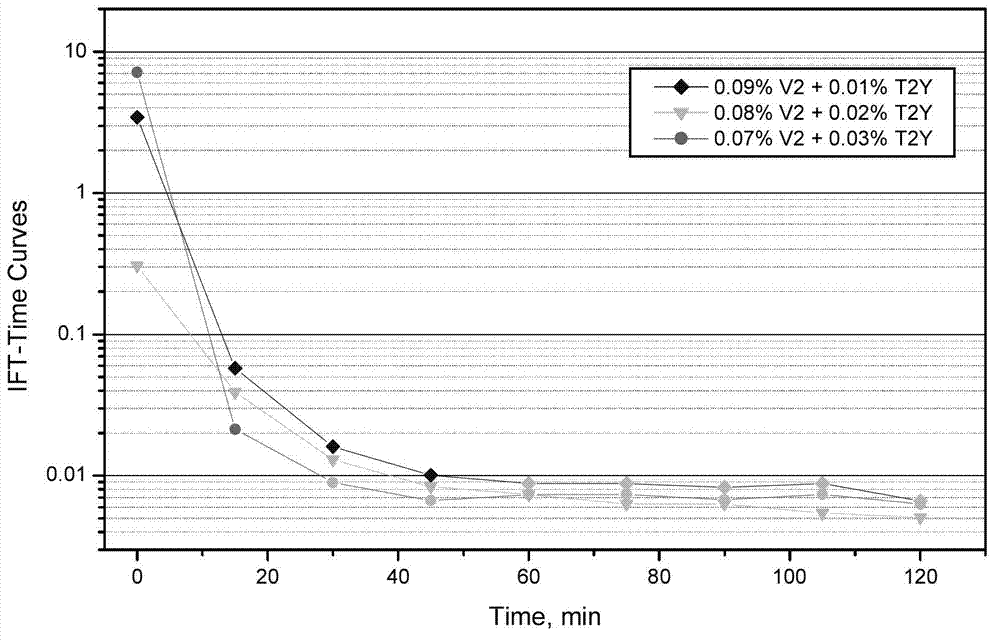

[0062] Interfacial Tension Test of Composite Surfactants with Different Compounding Ratio in Reservoir 1 Block 3 Conditions

[0063] The produced water (i.e., the formation water) of block 3 of the reservoir 1 was used to prepare solutions with a mass percent concentration of 0.10% of the composite surfactant, wherein the composite surfactant was erucamide propyl carboxybetaine (V2) and two Dodecyl hydroxypropyl sulfobetaine (T2Y), the weight ratio of the two is 90:10, 80:20, 70:30 respectively, and the interfacial tension between the above-mentioned various solutions and the crude oil in block 3 of reservoir 1 is measured . Test results such as image 3 shown.

[0064] Depend on image 3 It can be seen that when the compounding ratios of erucamidopropylcarboxybetaine (V2): docosyl hydroxypropyl sulfobetaine (T2Y) are 90:10, 80:20, and 70:30, the ultra-low The time corresponding to the interfacial tension is 45min, 37min and 30min, that is, with the increase of the content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com