Extraction method of plant active ingredient

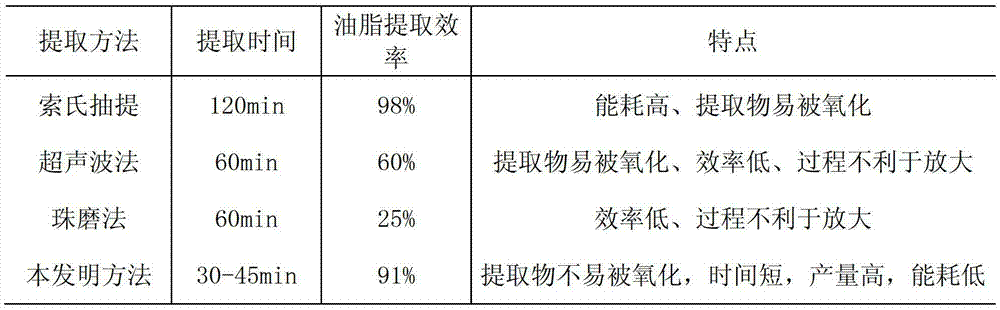

A plant active ingredient and extraction method technology, which is applied to the preparation of biodiesel and the fields of food and medicine, can solve the problems of high time and energy consumption, increased consumption and production cost, and low extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1: the extraction of oil and fat in chlorella

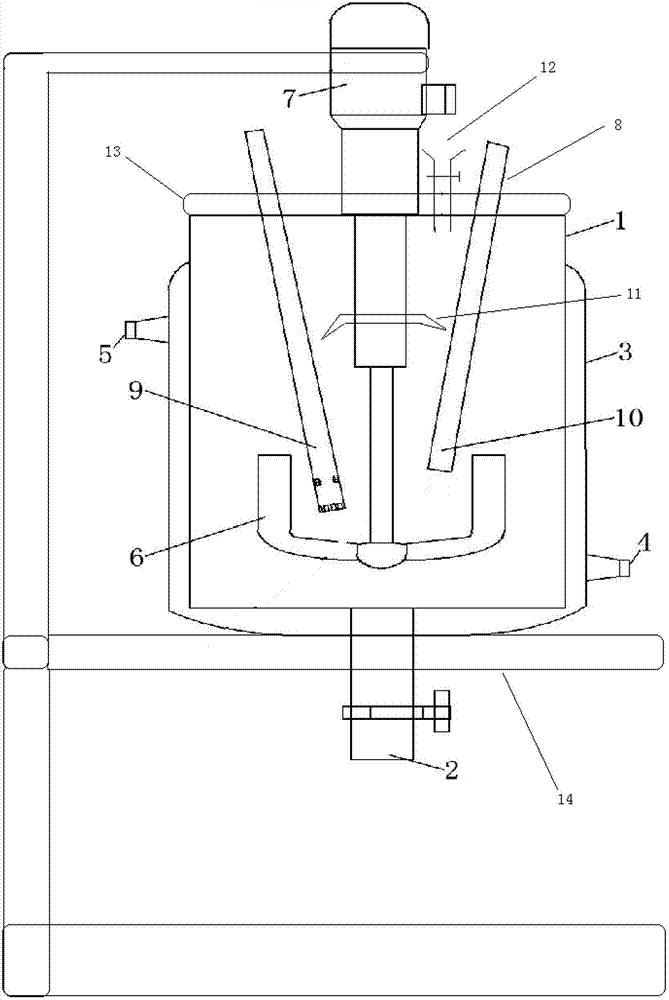

[0060] 1) Put the mass ratio of concentrated chlorella algae: water = 1:10, open the C-shaped clamp, start the lifting device, pour the mixture into the tank of the homogenizer, the total volume is 2 / 3V of the tank, and then rise tank and seal the tank.

[0061] 2) Start the anchor stirrer at a speed of 80r / min, and at the same time start the circulating water bath, control the temperature of the mixed material in the stirring tank to about 60oC, turn on the rotary blade 11 after 3 minutes, and stir at a speed of 150r / min for 5 minutes.

[0062] 3) Turn on the high-speed shear agitator, set the speed to 15000r / min, and turn on the ultrasonic generator at the same time, the ultrasonic power is 150W, and the frequency is 20KHZ.

[0063] 4) After working for 25 minutes, stop the high-speed shear agitator 9 and the rotary blade 11, set the temperature of the circulating water system at room temperature around 25oC,...

Embodiment 2

[0068] Embodiment 2: the extraction of orange peel essential oil

[0069] 1) Open the C-shaped clamp with the concentrated orange peel 1:15 (mass ratio orange peel: deionized water), start the lifting device, pour the mixture into the tank, the total volume is 3 / 4V of the tank, and then lift the tank body and seal the tank.

[0070] 2) Start the anchor agitator at a speed of 100r / min, and at the same time start the circulating water bath control, the temperature of the mixed material in the mixing tank is about 60oC, turn on the blade 11 after 3 minutes, the speed is 200r / min, and stir for 5 minutes.

[0071] 3) Turn on the high-speed shear agitator, set the speed to 15000r / min, and turn on the ultrasonic generator at the same time, the ultrasonic power is 200W, and the frequency is 20KHZ.

[0072] 4) After working for 30 minutes, stop all parts, first stop the high-speed shear agitator 9 and the rotating blade 11, then stop the high-speed shear and ultrasonic action, open th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com