Prestressed reinforced concrete solid square pile and manufacturing technique thereof

A reinforced concrete and prestressed technology, applied in sheet pile walls, foundation structure engineering, buildings, etc., can solve problems such as difficult to ensure uniform temperature field, difficult to control quality, low production efficiency, etc., to improve the mechanical properties of piles, The effect of improving crack performance and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

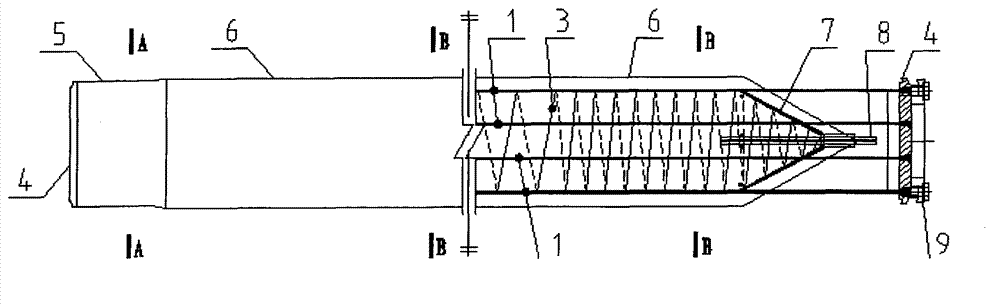

[0043] Such as figure 1 As shown, the present embodiment provides a prestressed reinforced concrete solid square pile, including a pile body 6, a pile cap 5 and a pile tip 7, wherein:

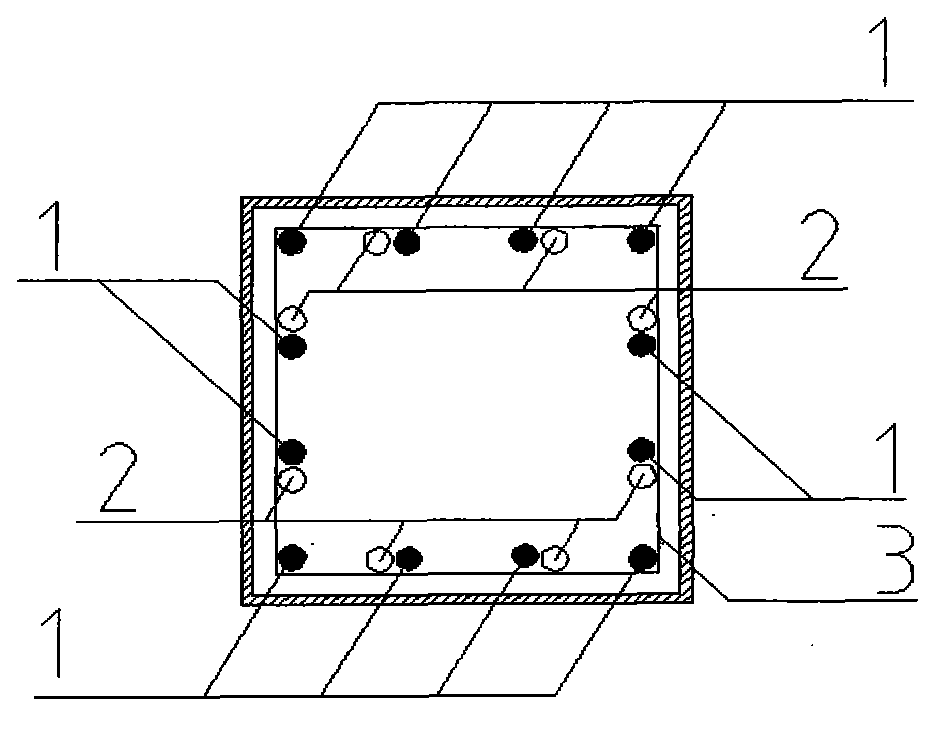

[0044] Described pile body 6 comprises concrete, pile body reinforcement cage, and described pile body reinforcement cage is square, is formed by roll welding of several longitudinal main reinforcements 1 and spiral stirrup 2; Described longitudinal main reinforcement 1 preferably adopts spiral groove steel bar, And its two ends are provided with piers; The cross-section main body of described pile body 6 is square, and side length is 600mm; or chamfering or any combination thereof; within the range of 150mm at both ends of the pile body reinforcement cage is a stirrup densification area, the spiral stirrup 2 pitch of the stirrup densification area is 50mm, and the spiral stirrup 2 pitch of the remaining areas is 85mm; in the present embodiment , the longitudinal main reinforcement 1 is 12, wh...

Embodiment 2

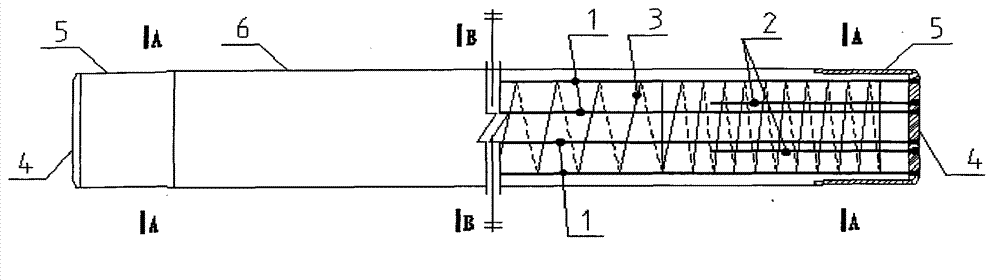

[0048] Such as figure 2 As shown, the present embodiment provides a prestressed reinforced concrete solid square pile, including a pile body 6, a pile cap 5 and a pile tip (not shown in the figure), wherein:

[0049] Described pile body 6 comprises concrete, pile body reinforcement cage, and described pile body reinforcement cage is square, is formed by roll-welding of several longitudinal main reinforcements 1 and spiral stirrup 2; The longitudinal main reinforcement 1 of described pile body reinforcement cage preferably adopts Spiral channel steel bar, and its two ends are provided with pier head; The cross section main body of described pile body 6 is square, and side length is 600mm; The four corners of the cross section of described pile body 6 are right angles or inner arc angles Or outer arc angle or chamfer or any combination thereof; within the range of 140mm at both ends of the pile body reinforcement cage is the stirrup density area, the spiral stirrup 2 pitch of t...

Embodiment 3

[0053] When the actual required square pile is longer, for the convenience of manufacture and transportation, it can be made in two sections, that is, an upper section pile is added at the pile cap end of the prestressed reinforced concrete solid square pile provided by the present invention, and the upper section The pile includes an upper section pile body and an upper section pile cap arranged at both ends of the upper section pile body. The structure of the upper section pile body and the upper section pile cap is consistent with the structure of the pile body and the pile cap in Embodiment 2. Herein No longer. For the convenience of pile cutting, the pile cap at the head end of the upper pile is only provided with an end plate, without pile hoops and anchor bars.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com