Locomotive booster pressure maintaining filtering system with memory self-checking function

A supercharger and functional technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve problems such as high precision requirements, harsh operating conditions, and many machine breakages and repairs, and achieve extended cleaning cycles and device structure. Simple and effective to improve filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

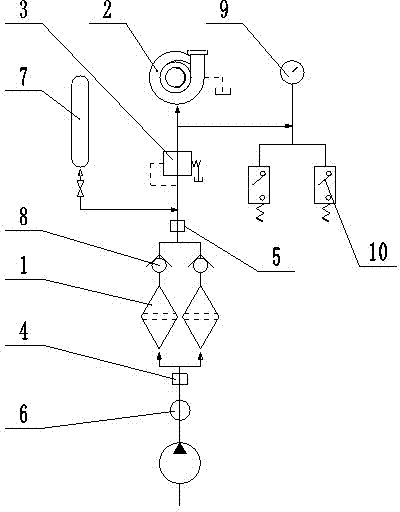

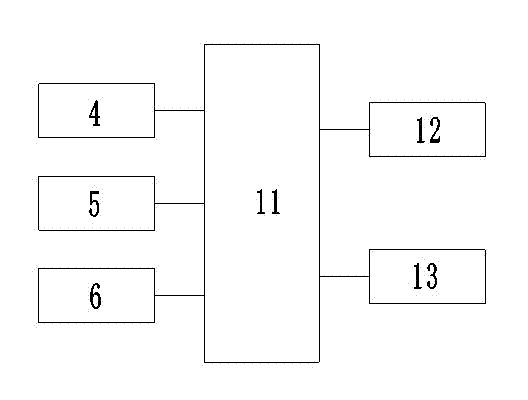

[0018] Such as figure 1 and figure 2 As shown, the present invention has a locomotive supercharger pressure maintaining filter system with memory self-checking function. The supercharger oil supply system is composed of a filter 1 and a supercharger 2. The oil inlets of 1 are connected through the oil pipe, the oil outlet of the filter 1 is connected with the lubricating oil pipeline inlet of the supercharger 2 through the pressure reducing valve 3, and the lubricating oil pipeline outlet of the supercharger 2 is connected with the oil tank; The oil inlet and the oil outlet of the filter 1 are respectively equipped with a first pressure sensor 4 for detecting the oil pressure at the oil inlet and a second pressure sensor 5 for detecting the oil pressure at the oil outlet. The first pressure sensor 4 and the signal output terminals of the second pressure sensor 5 are connected to the input port of the CPU chip 11, and the CPU chip 11 is connected with a display warning device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com