High-manganese medium-carbon peritectic steel continuous casting crystallizer casting powder and preparation method thereof

A continuous casting mold and mold powder technology, which is applied in the field of high manganese medium carbon peritectic steel continuous casting mold mold powder and its preparation, can solve problems such as breakout, deterioration of casting slab and mold lubrication, bonding, etc. , to achieve the effect of reducing the crack rate, avoiding bonding or even breakout, and avoiding crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

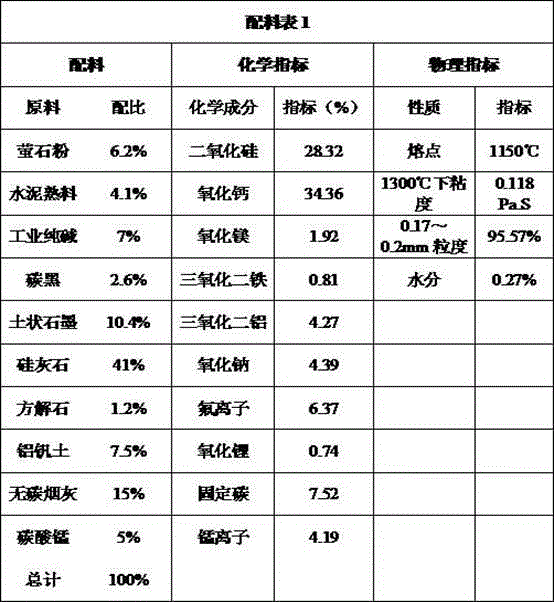

Embodiment 1

[0025]

[0026] Experimental process of steel plant A: test steel type: medium carbon peritectic steel, pouring section: 230*1030 mm, pouring temperature: 1535-1565 ℃, casting speed: 0.8-1.1 m / min;

[0027] Test quantity: 5.0 t;

[0028] After testing about 50 furnaces of nearly 6,000 tons of steel pouring, the results are as follows:

[0029] The crystallizer reflects small flame and less slag, and workers report that it is easy to operate. The quality of casting slabs has been greatly improved compared with the use of ordinary carbon steel mold flux, and the surface pass rate has increased to 99.27% from 73.45% in the previous month. It solves the problem of pits on the surface of ordinary carbon steel mold slag. At the same time, the analysis of the surface of the slab shows that the low-carbon mold slag of the billet has basically no carbon increase phenomenon.

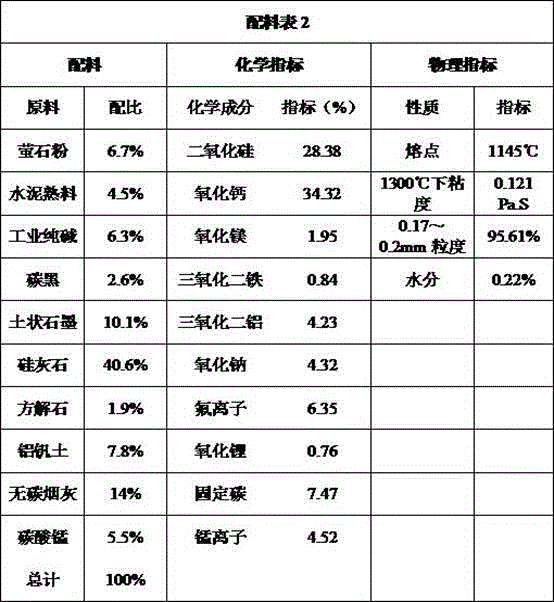

Embodiment 2

[0031]

[0032] B steel plant test process: steel type: medium carbon peritectic steel, section: 250*1700 mm, casting speed: 0.85~1.05 m / min.

[0033] During the test, it was observed that the mold powder has good spreadability in the crystallizer, moderate flame, active reaction, no agglomeration, no slag block, and even melting;

[0034] Liquid slag layer: the total slag layer is about 35 mm, and the liquid slag is kept stable at 10-12 mm;

[0035] Slag consumption: According to statistics, it is about 0.53 Kg / T, which is moderate;

[0036]During this experiment period, the molten steel level in the mold was extremely stable, there was no violent tumbling phenomenon at the edge, and the casting speed was stable at 1-1.05 m / min; during the tracking period, there was no phenomenon that the monitoring curve ran high, indicating that the slag mold The lubrication effect is ideal. There are no cracks or pits on the surface of the finished billet, and the surface qualified ra...

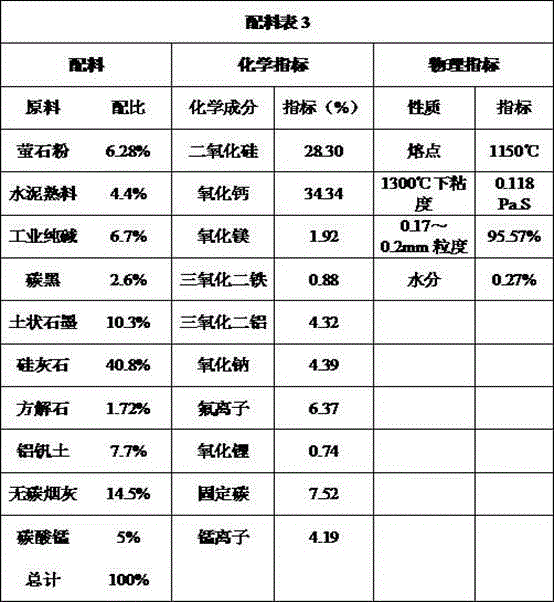

Embodiment 3

[0038]

[0039] Experimental process of C steel plant: test steel type: medium carbon peritectic steel, pouring section: 270*1800 mm, casting speed: 0.8~1.0 m / min;

[0040] During the test, it was observed that the mold slag spreads well in the crystallizer, the flame is moderate, the reaction is active, there is no agglomeration, no slag block, and the melting is uniform; the slag is less, and the workers report that it is easy to operate

[0041] Liquid slag layer: the total slag layer is about 30mm, and the liquid slag is kept stable at 11-13 mm;

[0042] Slag consumption: According to statistics, it is about 0.58 Kg / T, which is moderate;

[0043] During this experiment period, the liquid steel level in the mold was extremely stable, there was no violent tumbling phenomenon at the edge, and the casting speed was stable at 0.9-0.95 m / min; The lubrication effect is ideal. There are no cracks or pits on the surface of the finished billet, and the surface qualified rate ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com