Integrated preparation method for mogrosides

A technology of mogroside and mogroside, applied in the field of integrated preparation of mogroside, can solve the problems of long extraction time, occupation of equipment and space, low extraction efficiency, etc. The effect of extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

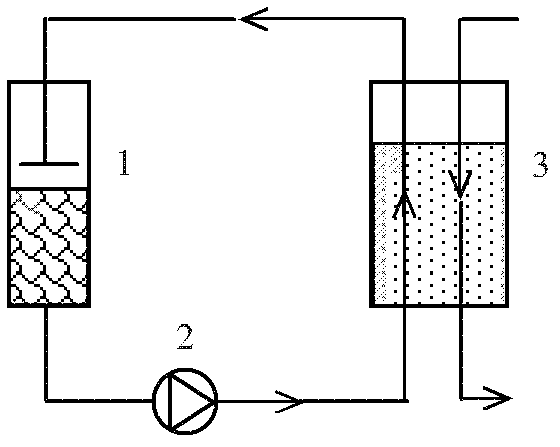

[0025] See attached figure 1 with 2 , An integrated preparation method of mogroside, the specific steps are:

[0026] (1) After crushing Luo Han Guo, take 15 g of coarse powder, place it in extractor 1, add 300 ml of deionized water extract according to the material-to-liquid ratio of 1:20, and turn on the ultrasonic instrument for extraction;

[0027] (2) Turn on the pump at the same time of extraction, and transport the extracted liquid to the processed HZ-806 macroporous adsorption resin expanded bed chromatography column, the expansion ratio of the column bed is 1.5. After the extraction liquid is adsorbed by the macroporous adsorption resin, the remaining adsorption liquid flows back to the extractor to continue to participate in the extraction, forming a dynamic extraction of the extraction liquid, so that mogroside is adsorbed on the column bed;

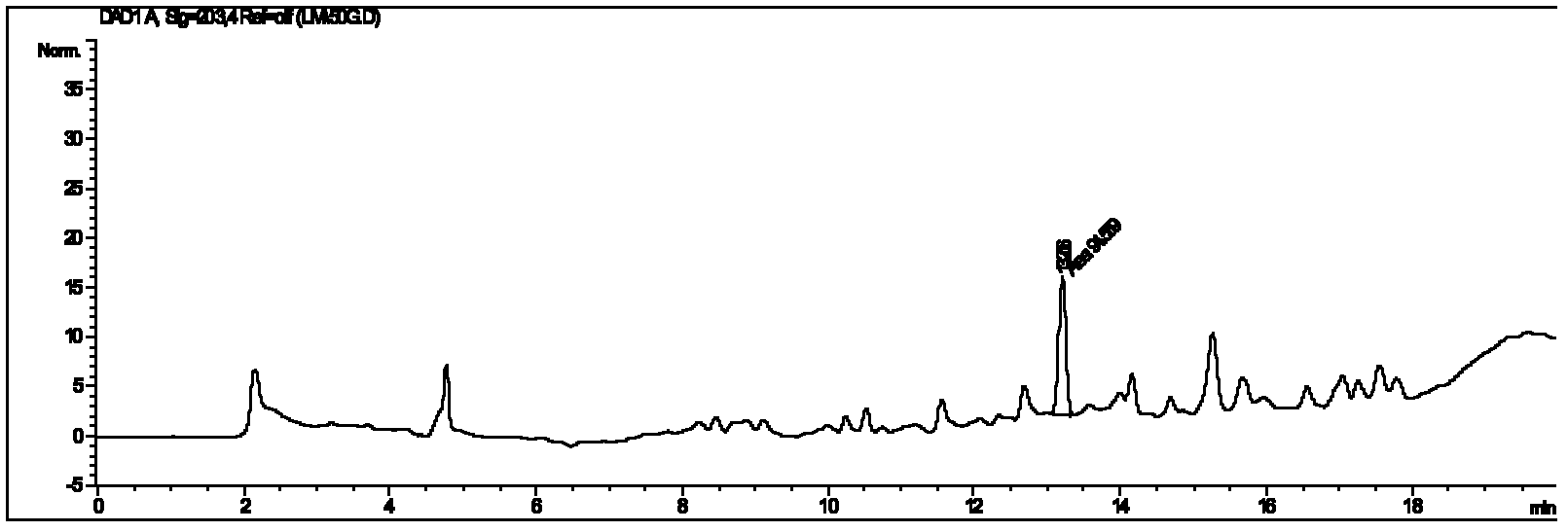

[0028] (3) After 3 hours of extraction, turn off the sonicator, and pump 1 column volume (80 mL) of deionized water into the expand...

Embodiment 2

[0031] See attached figure 2 , An integrated preparation method of mogroside, the specific steps are:

[0032] (1) After crushing Luo Han Guo, take 50 g of coarse powder, place it in an extractor, add 1000 ml of deionized water extract according to the material-to-liquid ratio of 1:20, and turn on the ultrasonic instrument for extraction;

[0033] (2) Turn on the pump at the same time of extraction, and transport the extracted liquid to the processed HZ-806 macroporous adsorption resin expanded bed chromatography column, the expansion ratio of the column bed is 1.5. After the extraction liquid is adsorbed by the macroporous adsorption resin, the remaining adsorption liquid flows back to the extractor to continue to participate in the extraction, forming a dynamic extraction of the extraction liquid, so that mogroside is adsorbed on the column bed;

[0034] (3) After 3 hours of extraction, turn off the sonicator, pump 1 column volume (80 mL) of deionized water into the expanded bed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com