Clear type sea-buckthorn fruit drink and production method thereof

A technology of seabuckthorn fruit juice and production method, which is applied in the field of food processing, can solve problems such as unfavorable juice clarification, inability to separate fruit from branches, etc., and achieve the effects of retaining nutrients, effective sterilization, and reducing inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

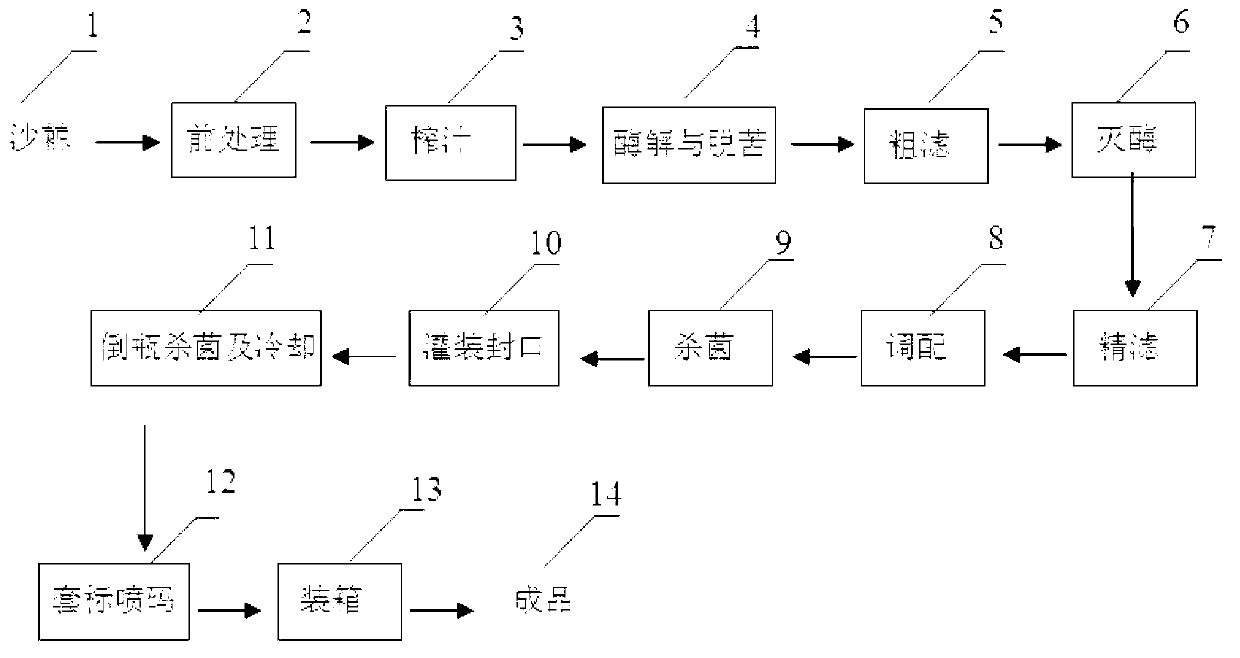

Method used

Image

Examples

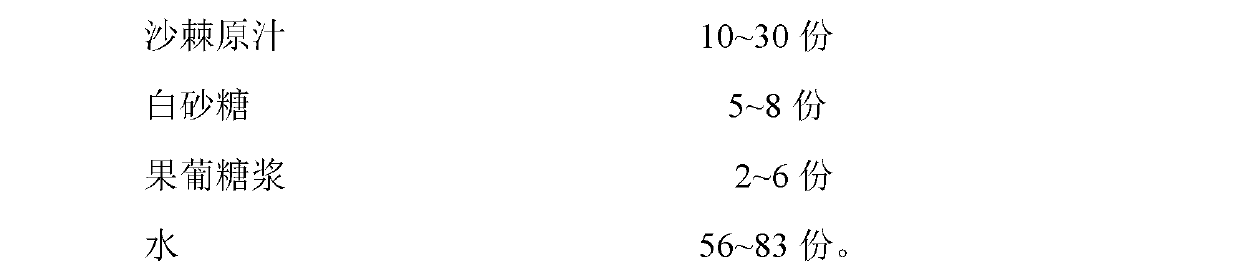

Embodiment 1

[0047] Select fresh seabuckthorn fruits with complete fruit shape, no mechanical damage, no rot, no diseases and insect pests, orange or orange red, and wash them with running water to remove dust and impurities; add the cleaned seabuckthorns to the feed hopper of the screw juicer The squeezed juice flows into the juice holder at the bottom through the filter screen, while the residue is discharged separately; put the squeezed sea buckthorn juice into a stainless steel reaction tank, add 0.04 parts of pectinase and concentration to 100 parts of sea buckthorn juice 10ml of 1% gelatin solution, reacted at 10r / min for 2 hours, and the reaction temperature was controlled at 30°C; the seabuckthorn juice after enzymatic hydrolysis and debittering was removed by a bag filter, and the pore size of the filter bag was 0.8μm; Seabuckthorn oil was then separated with a disc centrifuge; the rough filtered seabuckthorn juice was treated at 100°C for 1 min to inactivate enzymes; then finely f...

Embodiment 2

[0049]Select fresh seabuckthorn fruits with complete fruit shape, no mechanical damage, no rot, no diseases and insect pests, orange or orange red, and wash them with running water to remove dust and impurities; add the cleaned seabuckthorns to the feed hopper of the screw juicer The squeezed juice flows into the juice holder at the bottom through the filter screen, while the residue is discharged separately; put the squeezed sea buckthorn juice into a stainless steel reaction tank, add 0.10 parts of pectinase and concentration to 100 parts of sea buckthorn juice 12ml of 1% gelatin solution, reacted at a speed of 20r / min for 6h, and the reaction temperature was controlled between 40°C; the seabuckthorn juice after enzymatic hydrolysis and debittering was removed by a bag filter, and the pore size of the filter bag was 1.2 μm; then use a disc centrifuge to separate the seabuckthorn oil; the seabuckthorn juice after coarse filtration is treated at 100°C for 2 minutes to inactivat...

Embodiment 3

[0051] Select fresh seabuckthorn fruits with complete fruit shape, no mechanical damage, no rot, no diseases and insect pests, orange or orange red, and wash them with running water to remove dust and impurities; add the cleaned seabuckthorns to the feed hopper of the screw juicer The squeezed juice flows into the juice container at the bottom through the filter screen, while the residue is discharged separately; put the squeezed sea buckthorn juice into a stainless steel reaction tank, add 0.07 parts of pectinase and concentration to 100 parts of sea buckthorn juice 11ml of 1% gelatin solution, reacted at a speed of 15r / min for 4 hours, and the reaction temperature was controlled at 35°C; the seabuckthorn juice after enzymatic hydrolysis and debittering was removed by a bag filter with a pore size of 5μm; Use a disc centrifuge to separate the seabuckthorn oil; the coarsely filtered seabuckthorn juice is treated at 100°C for 1.5 minutes to inactivate the enzyme; Add 70 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com