Combined balance case and manufacturing method thereof

A manufacturing method and weighing machine technology, which are applied to a combination scale chassis and its manufacturing field, can solve the problems of increased volume of stamping dies and stamping equipment, increased energy consumption of stamping equipment, large stroke of stamping equipment, etc., so as to reduce equipment costs and improve equipment costs. Strength and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The manufacturing method of the combination weighing machine case of the present embodiment comprises the following steps:

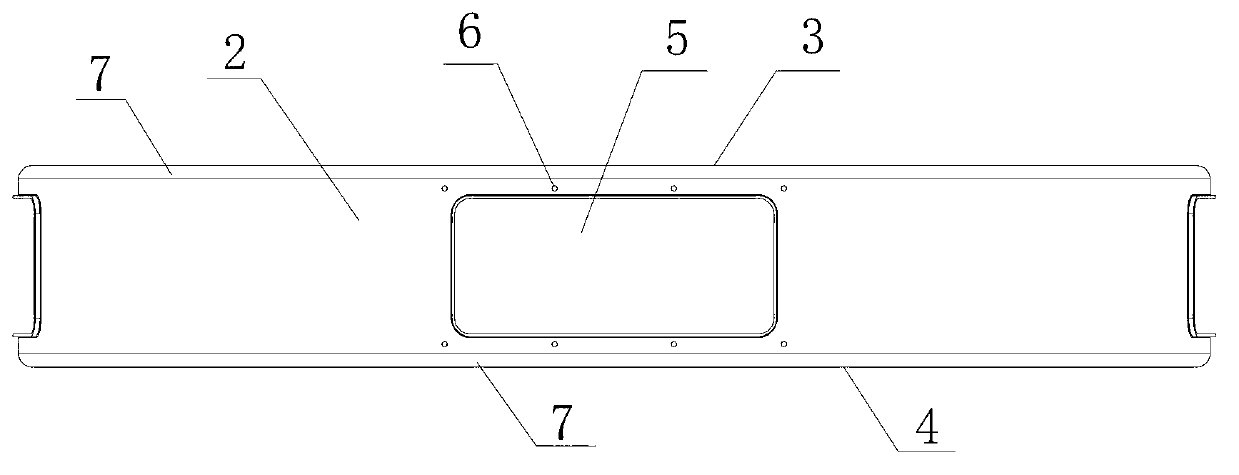

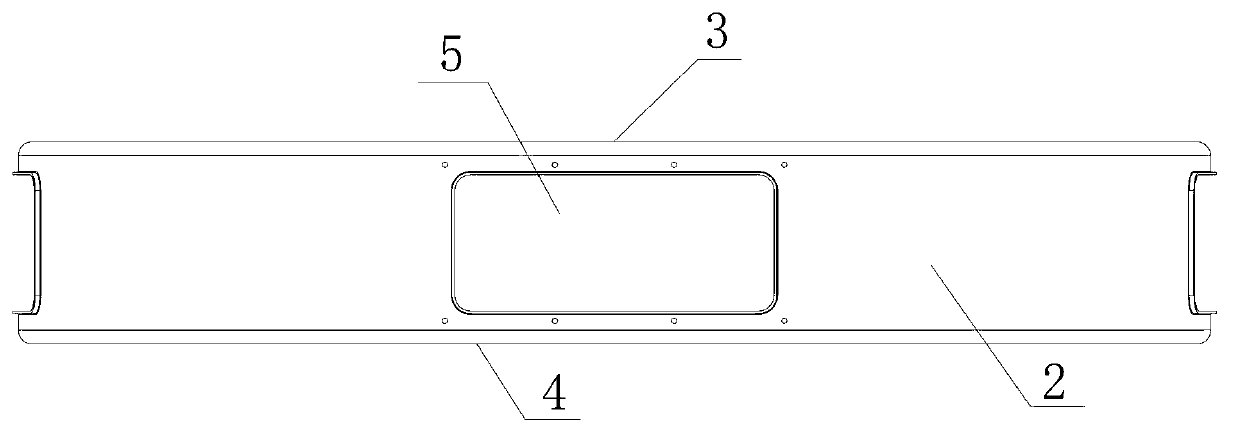

[0040](1) According to the expanded dimensions of the inner wall plate 1 and the outer wall plate 2, the precise contour lines of the inner wall plate and the outer wall plate are directly cut from the stainless steel plate at a ratio of 1:1, wherein the inner wall plate is one piece and the outer wall plate The boards are 4 pieces of the same size, and the outer contours of the four outer wall boards spliced together form the outer contour of the outer wall board 2 after expansion; according to the expanded size of the bottom board, a ring-shaped bottom board is cut from the stainless steel sheet, and the bottom board is also The contour line is directly and accurately cut out at a ratio of 1:1. The inner diameter and outer diameter of the cut bottom plate are smaller and larger than the diameters of the inner wall plate 1 and the outer wall pla...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that in this embodiment:

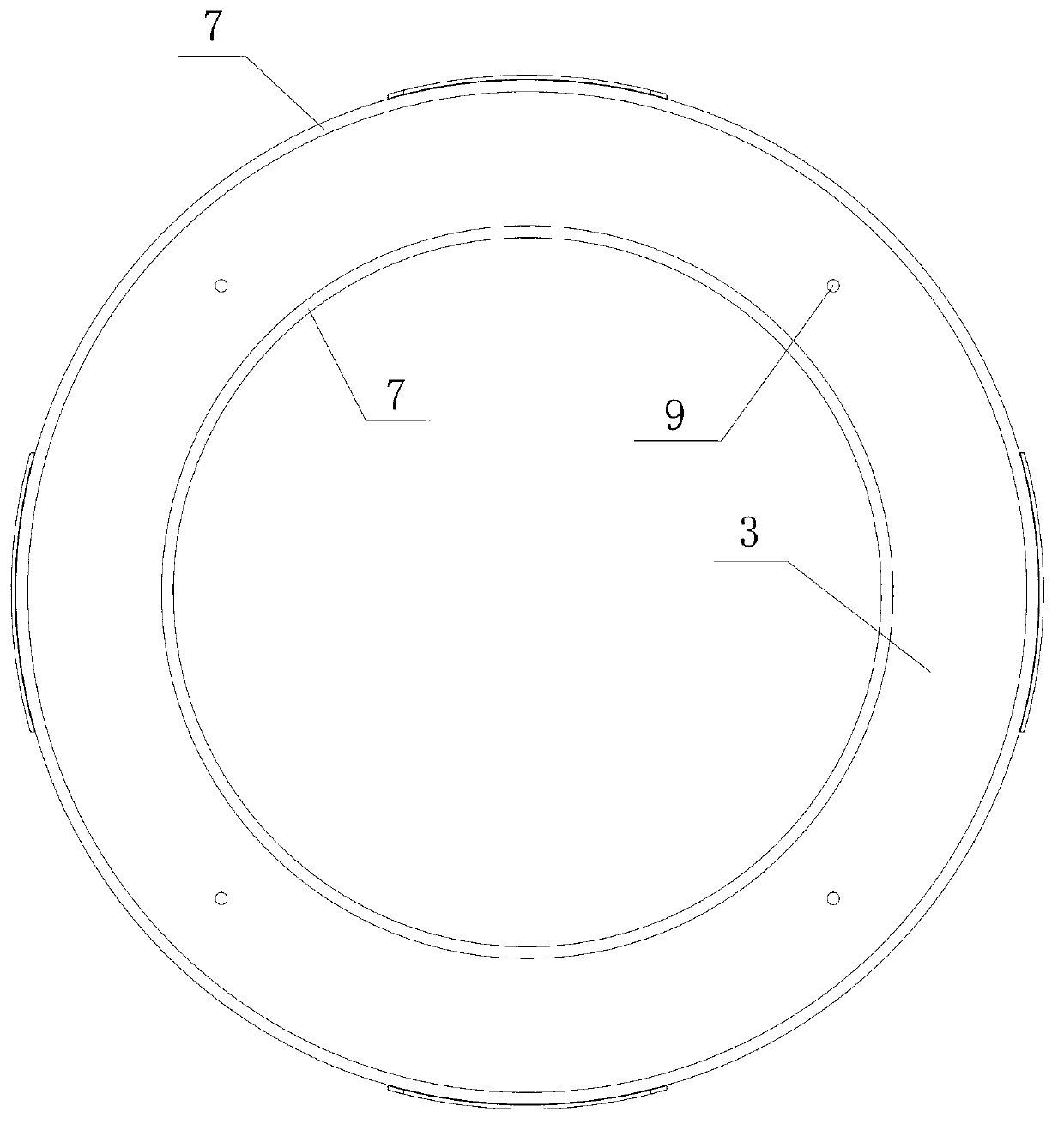

[0054] The outer wall panel 2 is welded by six splicing pieces 12, and each splicing piece 12 is provided with an installation window 5, and the six installation windows 5 on the entire outer wall panel 2 are evenly distributed in the circumferential direction.

[0055] The central angle of the arc part of the arc portion of the arc transition of the bottom plate is 60°.

[0056] In this embodiment, other implementations other than the above are carried out with reference to Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com