Moisture-retarding, oxygen-blocking and flavor-retaining packaging film with anti-fog function

A packaging film and moisture-blocking technology, applied in the field of moisture-blocking, oxygen-blocking, and fragrance-preserving thin packaging, can solve the problems of less involvement in the barrier of packaged fragrances, lack of a printed layer on the surface of the anti-fog film, and easy formation of fog on the packaging film. Achieve the effects of excellent long-lasting anti-fogging, excellent initial anti-fogging, and high curl resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

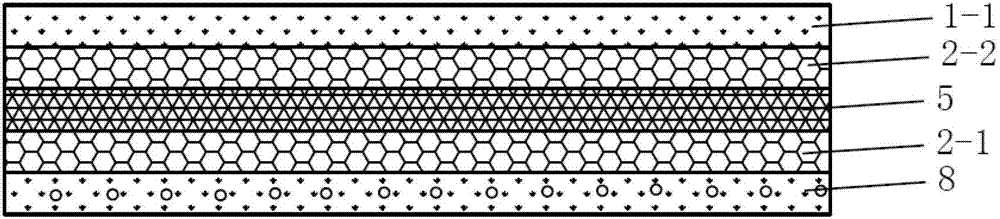

[0038] The invention is a moisture-proof, oxygen-proof and fragrance-preserving packaging film with anti-fog function. The film has a five-layer structure and is molded by co-extrusion blow molding. Such as figure 1 As shown, the structural expression of the film is: A / C / B* / C / A**; in the formula: from left to right, it represents the layers of the film from top to bottom, and A represents PE pure resin layer , is the moisture barrier layer; A** represents the PE resin layer added with anti-fogging agent, slip agent and anti-blocking agent, which is an anti-blocking, anti-fog, and moisture-blocking layer, in which 0.2 parts of anti-fog are added for every 100 parts of PE resin agent, 0.05 part of slip agent and 0.05 part of anti-blocking agent; C represents the maleic anhydride grafted PE resin layer, which is the adhesive layer; B* represents the EVOH resin layer, which is the oxygen barrier layer with fragrance retention function.

[0039] Here, PE is LLDPE; Antifogging agent ...

Embodiment 2

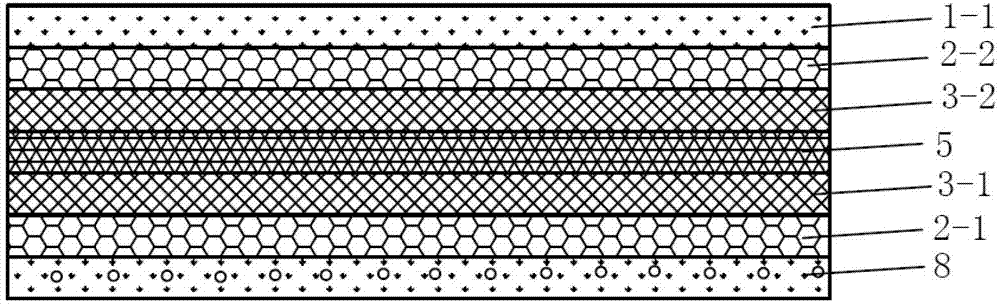

[0042] The invention is a moisture-proof, oxygen-proof and fragrance-preserving packaging film with anti-fog function. The film has a seven-layer structure and is molded by co-extrusion blow molding. Such as figure 2 As shown, the structural expression of the film is: A / C / B / B* / B / C / A**; in the formula: from left to right, it represents the layers of the film laid from top to bottom, and A represents PE pure resin layer is a moisture barrier layer; A** means PE resin layer added with anti-fogging agent, slip agent and anti-blocking agent, which is an anti-blocking, anti-fog and moisture-blocking layer, in which every 100 parts of PE resin is added with 3 parts of anti-fogging agent, 1 part of slippery agent and 1 part of anti-blocking agent; C means maleic anhydride grafted PE resin layer, which is the adhesive layer; B means PA resin layer, which is the oxygen barrier layer; B* means EVOH resin The layer is an oxygen barrier layer with fragrance retention function.

[0043] ...

Embodiment 3

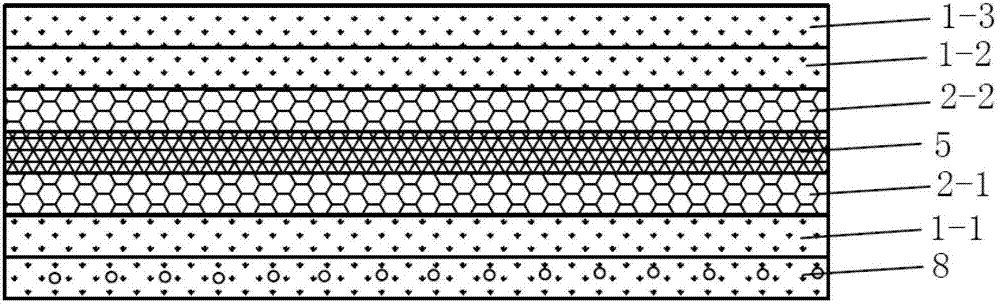

[0046] The invention is a moisture-proof, oxygen-proof and fragrance-preserving packaging film with anti-fog function. The film has a seven-layer structure and is molded by co-extrusion blow molding. Such as image 3 As shown, the structural expression of the film is: A / A / C / B* / C / A / A**; in the formula: from left to right, the layers of the film are sequentially laid from top to bottom, and A represents PE pure resin layer is a moisture barrier layer; A** means PE resin layer added with anti-fogging agent, slip agent and anti-blocking agent, which is an anti-blocking, anti-fog and moisture-blocking layer, in which every 100 parts of PE resin is added with 0.5 parts of anti-fogging agent, 0.2 parts of slippery agent and 0.2 parts of anti-blocking agent; C represents the maleic anhydride grafted PE resin layer, which is the bonding layer; B* represents the EVOH resin layer, which is the oxygen barrier layer with the function of maintaining fragrance .

[0047] Here, PE is a mixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com