Method and device for destructive distillation of oil shale

A technology of oil shale and dry distillation, which is applied in special forms of dry distillation, petroleum industry, coke oven, etc. It can solve the problems of low oil production rate of oil shale dry distillation, large device structure size, and large shale ash discharge, etc., to achieve Effects of reduced equipment investment, reduced device energy consumption, and reduced total coke air consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

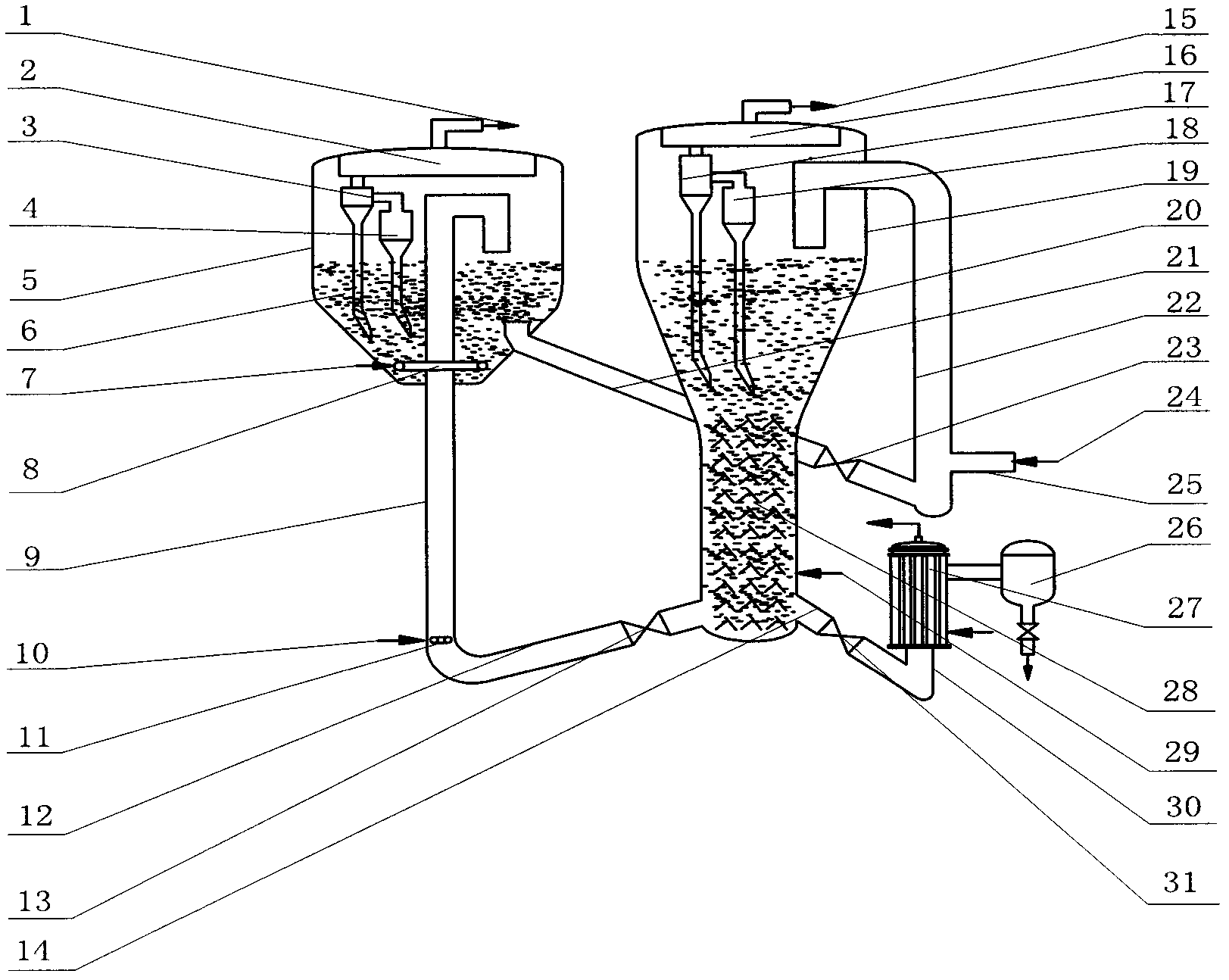

Image

Examples

Embodiment 1

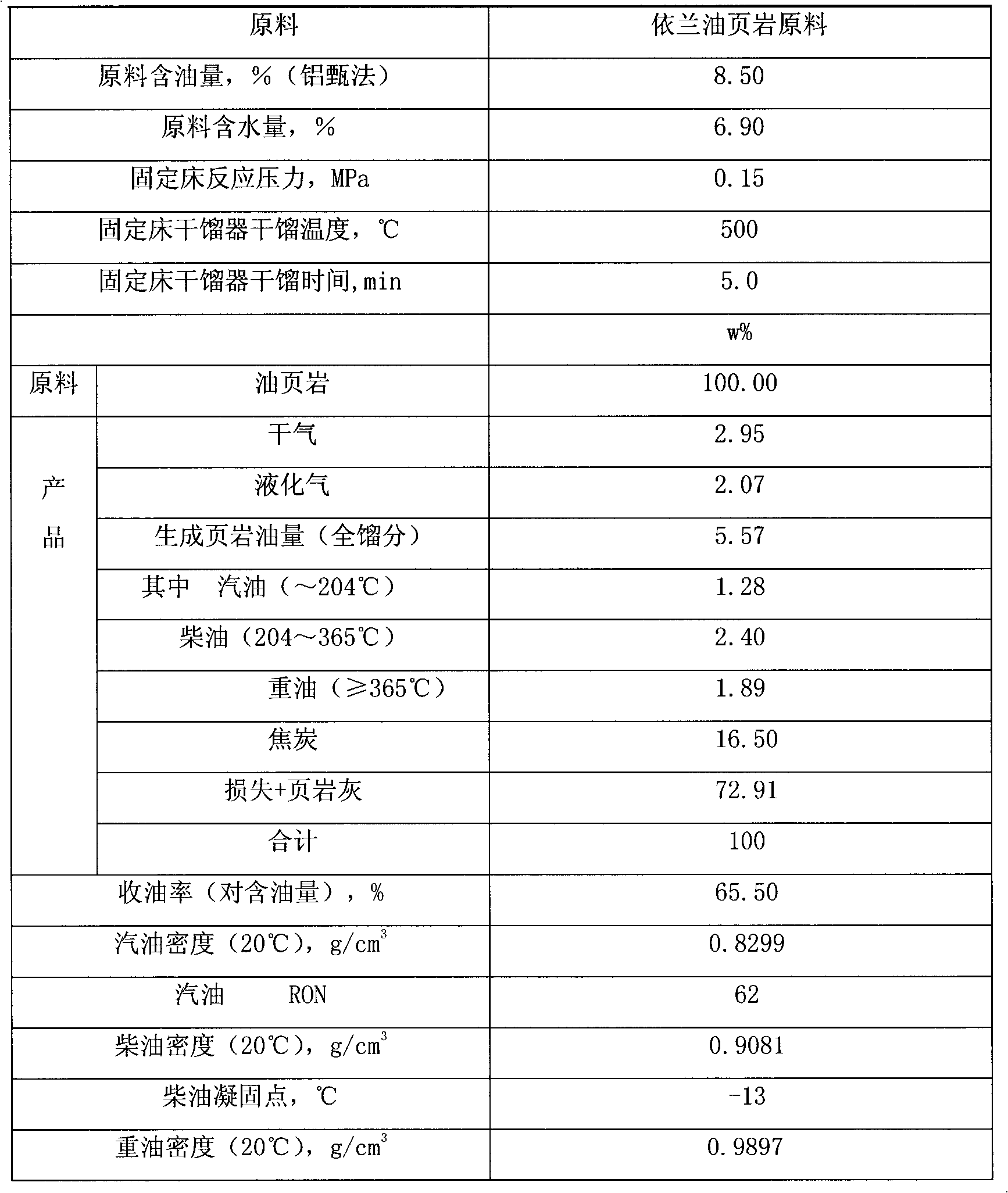

[0074] Ylang-ylang oil shale was used as granular raw material, and the properties of the raw material are shown in Table 3.

[0075] The dry distillation of oil shale is carried out on a laboratory fluidized bed device. The semi-coke is fired in a tube type and then enters the charcoal burner for charcoal burning. The regenerated semi-coke enters the charcoal burner and the temperature of the charcoal burner is controlled by the main air volume. The stripping medium in the stripping section of the dry distillation reactor is water vapor, and the stripping temperature is 500°C. See Table 4 for the operating conditions, product distribution and properties of some products of the shale oil carbonization device in this example.

Embodiment 2

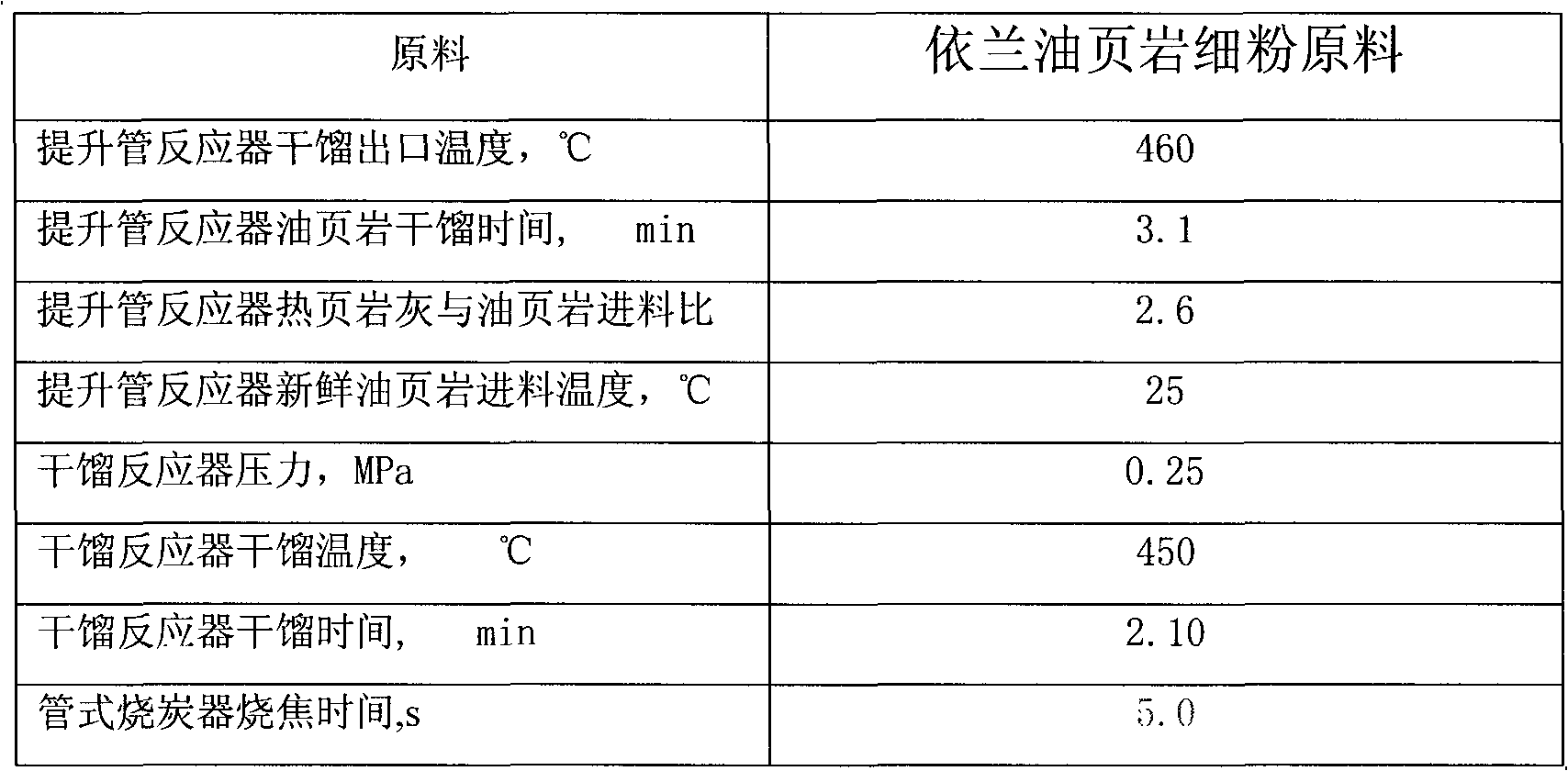

[0077] According to Example 1, the difference is the temperature of the charcoal burner, the time of the charcoal burner, the weight ratio of the oil shale particle raw material to the high-temperature shale ash, the carbonization time of the carbonization reactor, the carbonization temperature of the carbonization reactor, and the tubular charcoal. The charring time of the tube charcoal burner, the line speed of the tubular charcoal burner, the oil shale carbonization time of the riser reactor and the carbonization outlet temperature of the riser reactor. See Table 5 for the operating conditions, product distribution and properties of some products of the shale oil carbonization device in this example.

Embodiment 3

[0079] According to Example 1, the difference is the temperature of the charcoal burner, the time of the charcoal burner, the weight ratio of the oil shale particle raw material to the high-temperature shale ash, the carbonization time of the carbonization reactor, the carbonization temperature of the carbonization reactor, and the tubular charcoal. The charring time of the tube charcoal burner, the line speed of the tubular charcoal burner, the oil shale carbonization time of the riser reactor and the carbonization outlet temperature of the riser reactor. See Table 6 for the operating conditions, product distribution and properties of some products of the shale oil carbonization device in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com