Multi-stage serial fluidized bed reactor and method for methanol to olefins

A fluidized bed reactor, methanol to olefins technology, applied in the direction of hydrocarbon production from oxygen-containing organic compounds, organic chemistry, chemical recovery, etc., can solve the problems of different reactor sizes, temperatures, loads, and limited reaction conditions , to achieve the effect of narrow distribution of carbon deposition, narrow distribution of residence time, and reduction of entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

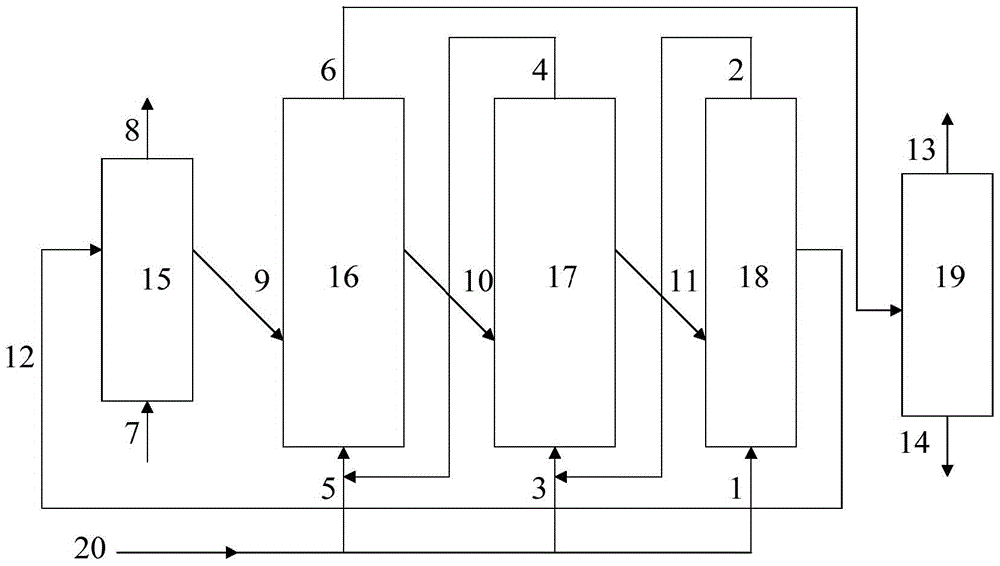

[0046] The results for single-stage reactors are considered first, as a comparison for subsequent consideration of multi-stage reactors. figure 2 Shown is a pilot-scale single fluidized bed reactor with its accessories. The diameter of the reactor is 0.26m, and the operating gas velocity is 0.6m / s, which belongs to the type of turbulent fluidized bed. The mass flow rate of the methanol feed is 41.5kg / h, the water content of the feed is 20%, the catalyst loading is 10.4kg, the reaction temperature is 480°C, the pressure is 0.1MP, and the average residence time of the catalyst in the reactor is 45min. The SAPO-34 catalyst used is a DMTO catalyst produced by Dalian Institute of Chemical Physics, with a specific surface area of 263m 2 / g, average particle size 83μm, particle density 1220kg / m 3 . The raw methanol aqueous solution all enters the reactor 16 through the feed channel 5, and the reacted outlet material enters the subsequent olefin separation device 19 through the ...

Embodiment 2

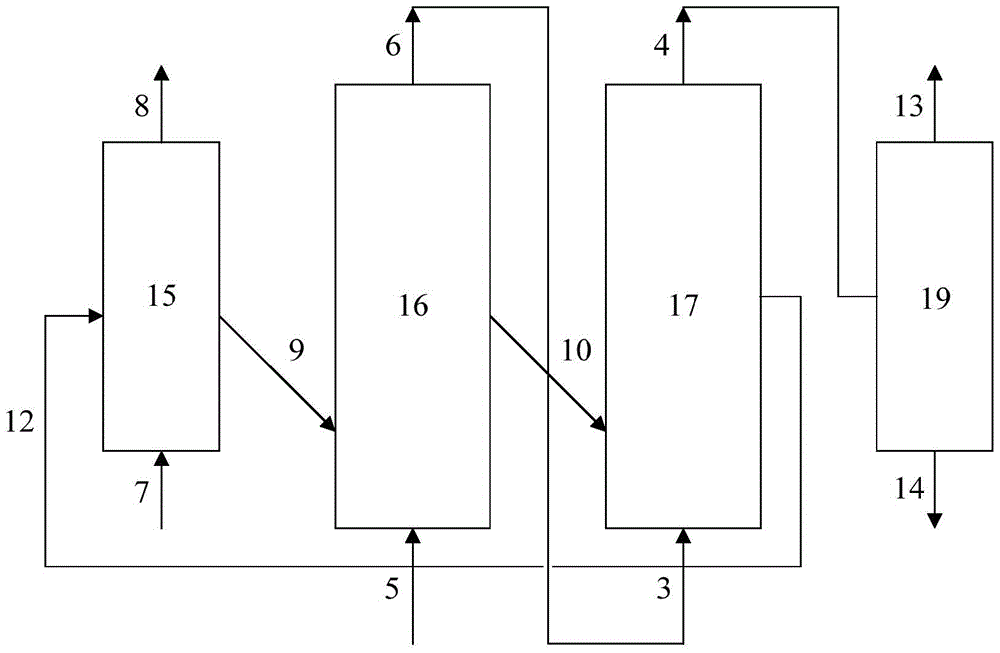

[0050] use image 3 In the two-stage gas-solid co-flow reactor shown, the size of the two reactors is the same, the catalyst loading of each reactor is half of that of the single-stage reactor, and the gas velocity is still the same as that of the single-stage reactor, all of which belong to turbulent fluidization bed type. The raw methanol aqueous solution enters the first-stage reactor 16 through the feed channel 5, and the reacted outlet material enters the second-stage reactor 17 through the gas outlet 6 and the feed channel 3 to continue the reaction, and the reacted outlet material passes through the gas outlet 4 Enter the subsequent olefin separation device 19, after separation, the products ethylene and propylene are obtained from the outlet 13, and other by-products are obtained from the outlet 14. The fresh catalyst output from the regenerator 15 enters the first-stage reactor 16 through the circulation channel 9, where pre-coking is performed and the methanol feed is...

Embodiment 3

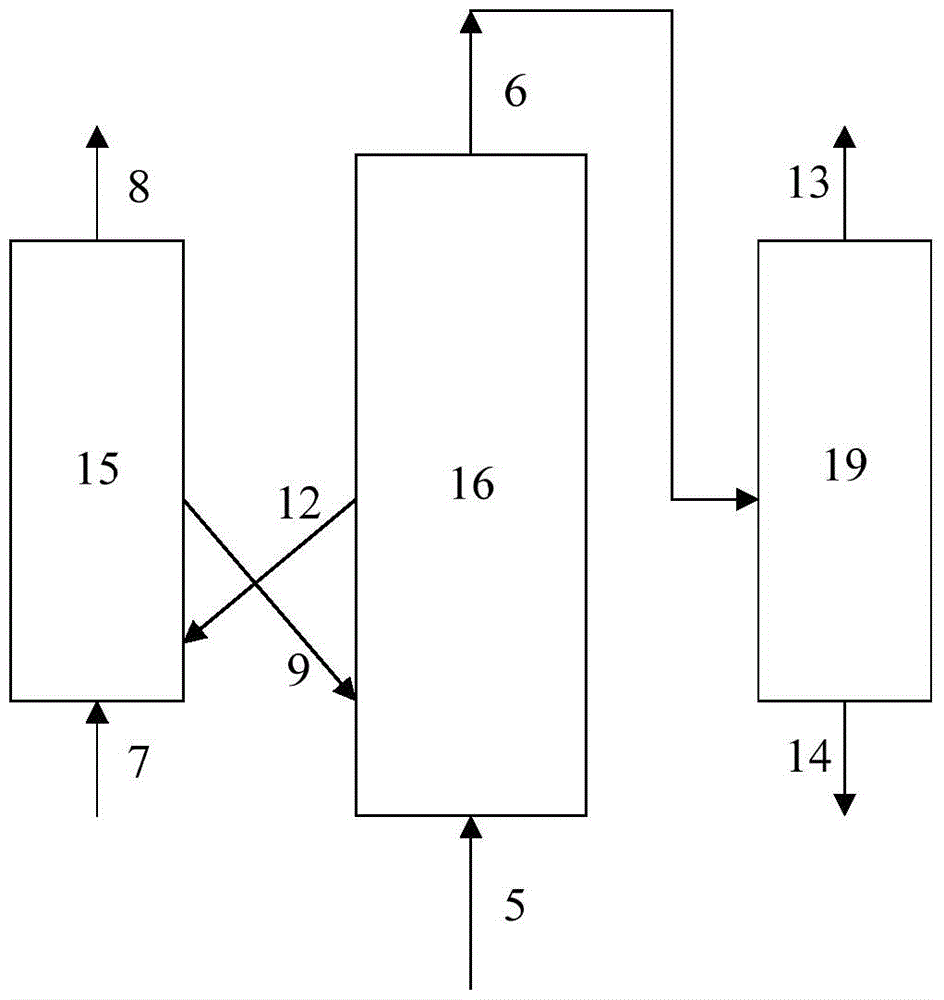

[0054] use Figure 4 In the two-stage gas-solid countercurrent reactor shown, the size and type of the reactor are still the same as in Example 2, except that the gas-solid countercurrent contact is adopted. The operating conditions are the same as in Table 2. Raw methanol aqueous solution all enters the second-stage reactor 17 through the feed channel 3, and the reacted outlet material enters the first-stage reactor 16 through the gas outlet 4 and the feed channel 5 to continue the reaction. The exported material enters the subsequent olefin separation device 19 through the gas outlet 6, and after separation, the products ethylene and propylene are obtained from the outlet 13, and other by-products are obtained from the outlet 14. The fresh catalyst output from the regenerator 15 enters the first-stage reactor 16 through the circulation channel 9, performs pre-coking and fully converts the remaining methanol, and the pre-coke catalyst output from the first-stage reactor 16 en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com