Pre-treating agent for surfaces of aluminum profile and aluminum alloy profile

A technology of aluminum alloy surface and pretreatment agent, which is applied in the direction of metal material coating process, etc., can solve the problems such as unsatisfactory effect of pretreatment agent, and achieve the effects of stable properties, avoiding environmental pollution, and good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

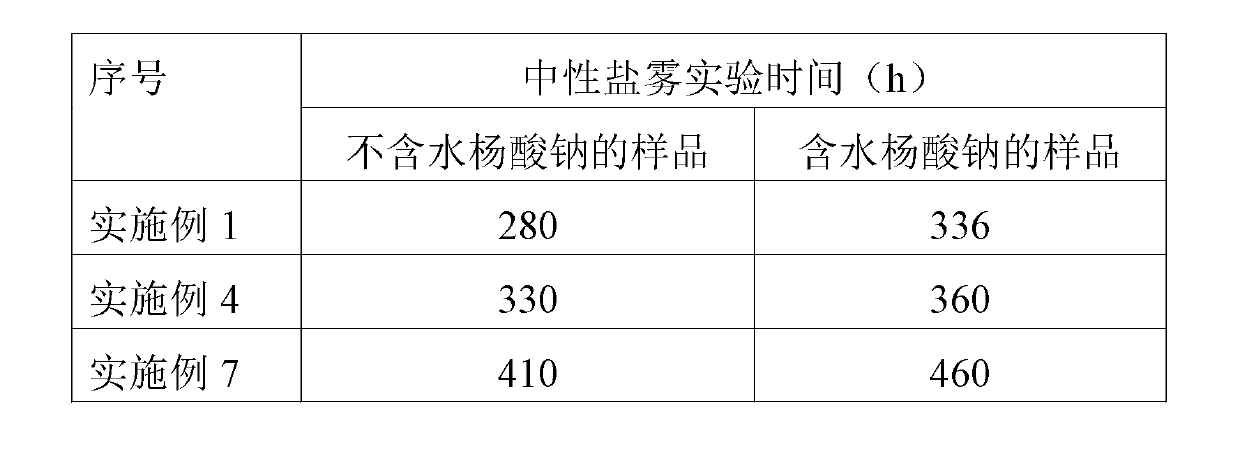

Examples

Embodiment 1

[0017] Dissolve 38g of potassium chromium sulfate, 3g of potassium hexafluorozirconate, 1.6g of sodium salicylate, 10g of hydroxypropyl cellulose, and 6g of sorbitan monopalmitate in 41.4g of water to obtain pretreatment for aluminum and aluminum alloy surfaces Agent 1.

Embodiment 2

[0019] Dissolve 40g of potassium chromium sulfate, 2.5g of potassium hexafluorozirconate, 1.2g of sodium salicylate, 9g of methylcellulose, and 5.5g of sodium lauryl sulfate in 41.8g of water to obtain a pretreatment agent for aluminum and aluminum alloy surfaces 2.

Embodiment 3

[0021] Dissolve 35g of potassium chromium sulfate, 2.0g of potassium hexafluorozirconate, 1.8g of sodium salicylate, 8g of ethyl cellulose, 1g of hydroxyethyl cellulose, and 7g of methyleneoxyethanol in 45.2g of water to obtain aluminum and aluminum alloys Surface pretreatment agent 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com