Numerical control precision control ultrasonic dyeing microwave drying production line

A technology of microwave drying and precise control, applied in textile and paper making, vibration treatment, equipment configuration for processing textile materials, etc. Drying quality and guaranteed leather yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

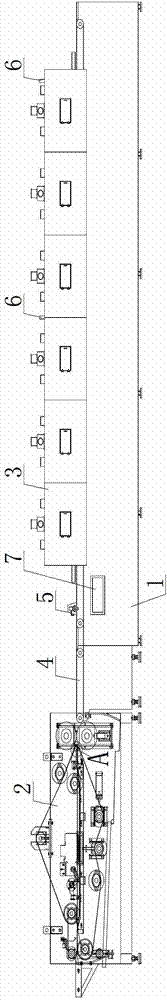

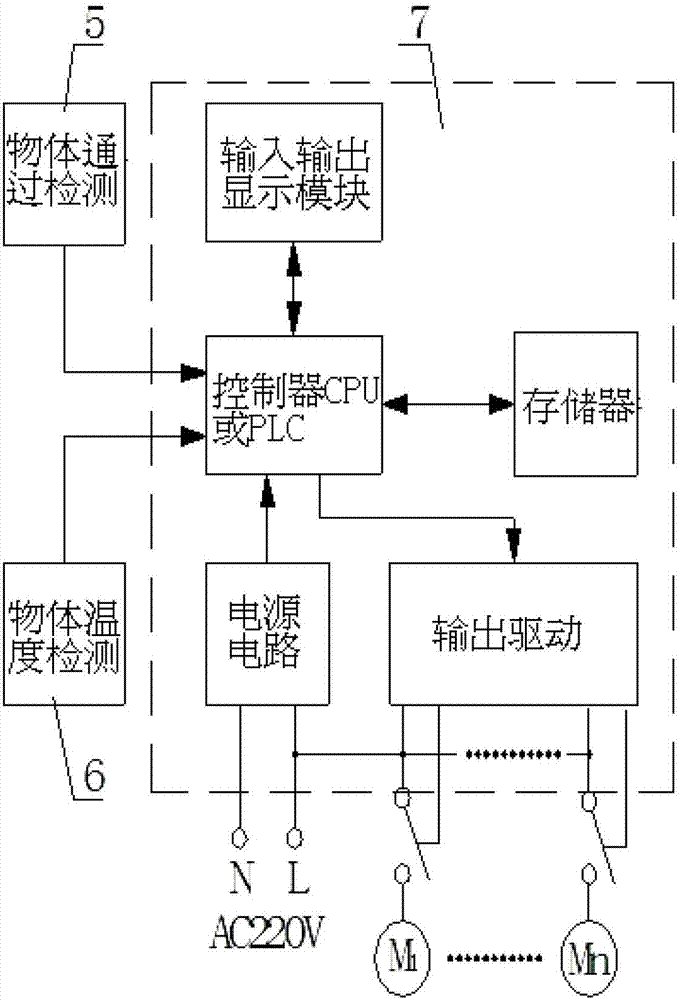

[0017] refer to figure 1 As shown, the digitally controlled precision control ultrasonic dyeing microwave drying production line of the present invention includes a frame 1, including a frame 1, and a through-type ultrasonic dyeing machine 2 and a microwave drying tunnel 3 are sequentially installed on the frame 1. The discharge port of the passage-type ultrasonic dyeing machine 2 and the feed port of the microwave drying tunnel 3 are connected by a conveyor belt 4, and a material passing detection device 5 is provided on the frame 1 corresponding to the conveyor belt 4. The microwave drying tunnel 3 is provided with a material temperature detection device 6, and the frame 1 is provided with a controller 7, and the working control signal lines of the through-type ultrasonic dyeing machine 2, the microwave drying tunnel 3, and the conveyor belt 4 are all connected to control 7, the signal output lines of the material passing detection device 5 and the temperature detection devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com