Vacuum drying technique of polytetrafluoroethylene resin with ultra-high molecular weight

A polytetrafluoroethylene, ultra-high molecular weight technology, applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of adverse effects of resin processing, additive residues, removal, etc., and achieve easy recycling or treatment, resin purity, low total exhaust gas effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

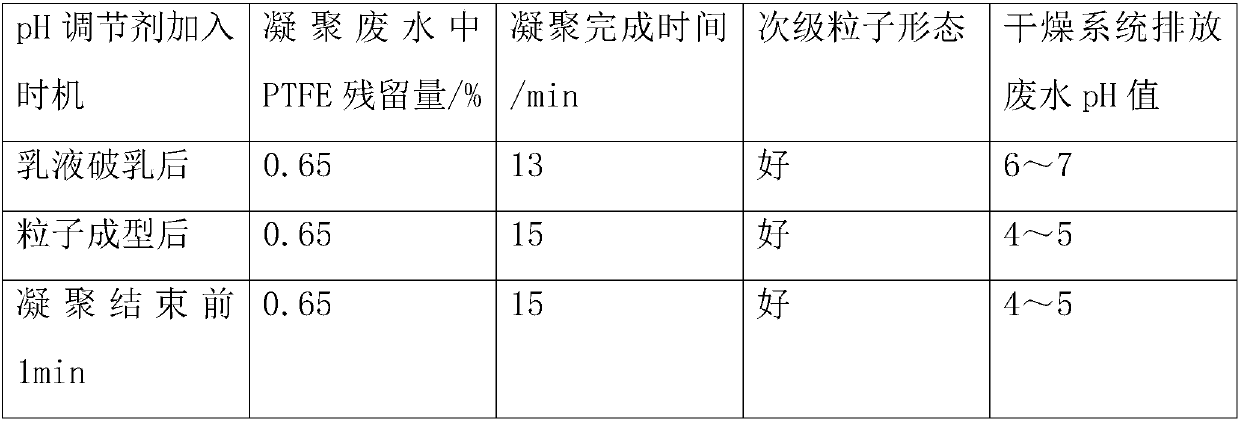

Examples

Embodiment 1

[0037] A vacuum drying process method for ultra-high molecular weight polytetrafluoroethylene resin, comprising the following steps:

[0038] 1) First clean the polymerization kettle, and add paraffin, tetrafluoroethylene and additives into the polymerization kettle according to the designed ratio. It is perfluorooctanoic acid, the stabilizer is paraffin, preferably the paraffin with a melting point of 60°C, and the initiator is ammonium persulfate, then add high-purity water, seal the polymerization kettle, replace it with nitrogen after evacuating, and pass through the mixer when the oxygen content is 20-30ppm Stir and mix evenly, control the polymerization temperature to 70°C, and control the polymerization pressure to 15Kg / cm 2 , the stirring speed is 50r / min, and the continuous stirring time is 80min. After filtration, the monomer is recovered, evacuated and nitrogen is used to restore the internal pressure of the polymerization tank to normal pressure;

[0039] 2) takin...

Embodiment 2

[0044] A vacuum drying process method for ultra-high molecular weight polytetrafluoroethylene resin, comprising the following steps:

[0045]1) First clean the polymerization kettle, and add paraffin, tetrafluoroethylene and additives into the polymerization kettle according to the designed ratio. It is perfluorooctanoic acid, the stabilizer is paraffin, preferably the paraffin with a melting point of 60°C, the initiator is potassium persulfate, then add high-purity water, seal the polymerization kettle, replace it with nitrogen after evacuating, and pass through the mixer when the oxygen content is 20-30ppm Stir and mix evenly, control the polymerization temperature to 75°C, and control the polymerization pressure to 20Kg / cm 2 , the stirring speed is 70r / min, and the continuous stirring time is 90min. After filtering, the monomer is recovered, evacuated and nitrogen is used to restore the internal pressure of the polymerization tank to normal pressure;

[0046] 2) taking out...

Embodiment 3

[0051] A vacuum drying process method for ultra-high molecular weight polytetrafluoroethylene resin, comprising the following steps:

[0052] 1) First clean the polymerization kettle, and add paraffin, tetrafluoroethylene and additives into the polymerization kettle according to the designed ratio. It is perfluorooctanoic acid, the stabilizer is paraffin, preferably the paraffin with a melting point of 60°C, the initiator is sodium persulfate, then add high-purity water, seal the polymerization kettle, replace it with nitrogen after evacuating, and pass through the mixer when the oxygen content is 20-30ppm Stir and mix evenly, control the polymerization temperature to 80°C, and control the polymerization pressure to 25Kg / cm 2 , the stirring speed is 80r / min, and the continuous stirring time is 100min. After filtering, the monomer is recovered, evacuated and nitrogen is used to restore the internal pressure of the polymerization tank to normal pressure;

[0053] 2) taking out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com