Intelligent protection net

A protective net and intelligent technology, applied in the field of transportation technology and civil engineering, geotechnical engineering, can solve the problems that the force value sensing device is susceptible to electromagnetic interference, cannot adapt to field environmental conditions, and the monitoring equipment is expensive, etc., achieving good application prospects, The effect of flexible use and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

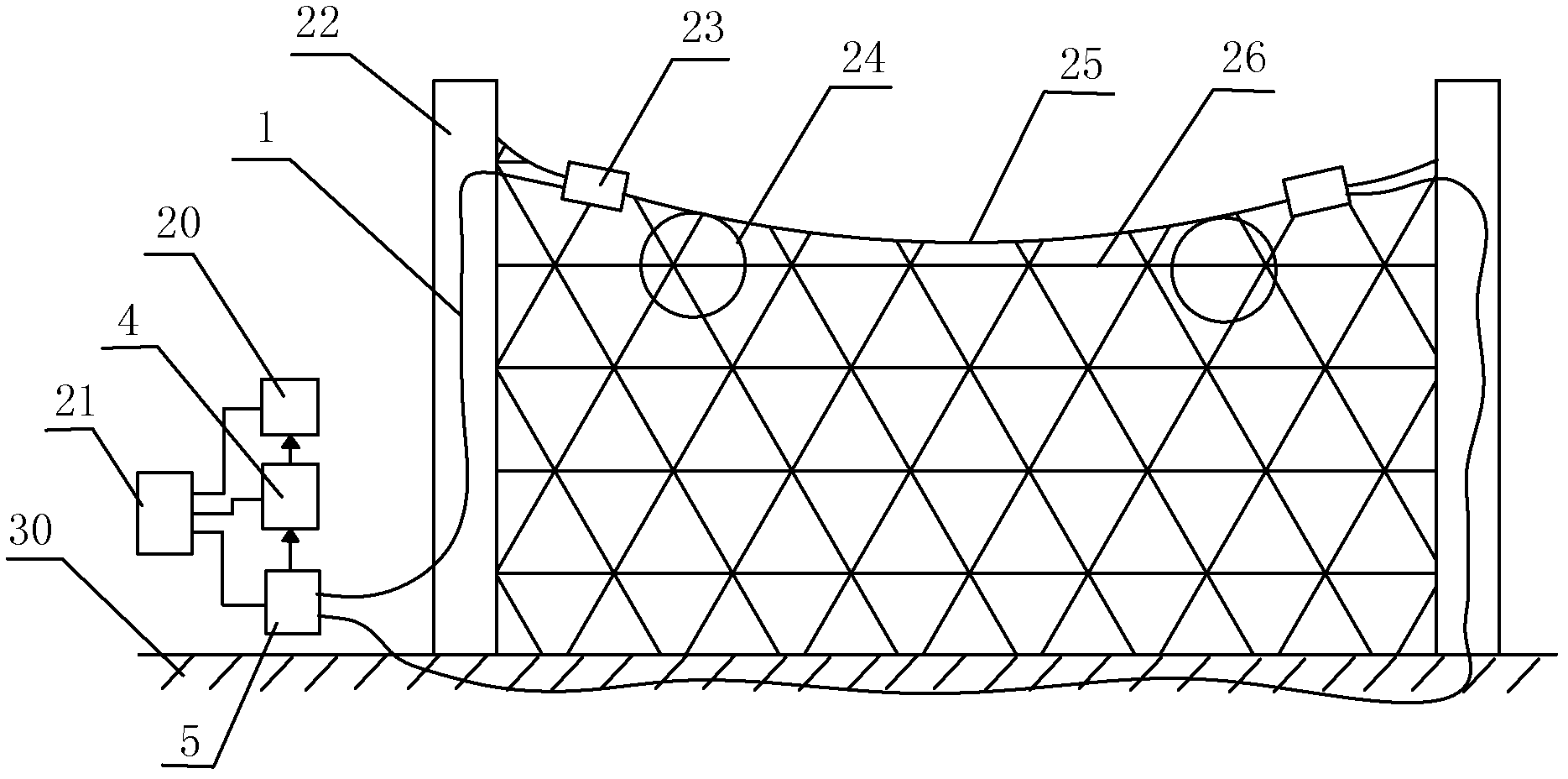

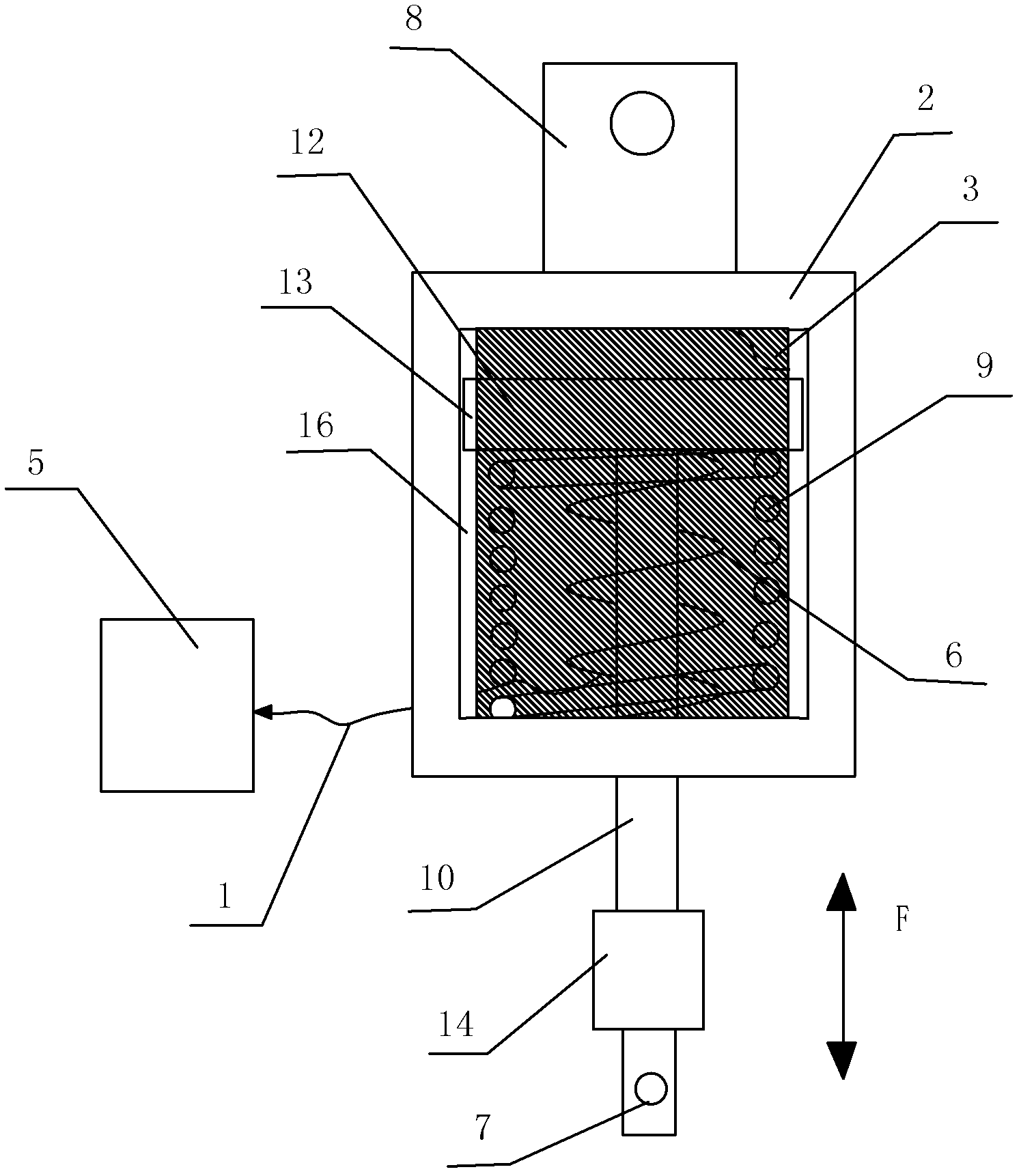

[0039] like figure 1 , 2 , a kind of intelligent protective net shown in 3, 4, comprises the column 22 that is fixed on the ground 30 and the protective net 26 that is installed between the column 22, and the top of described protective net 26 is provided with dragline 25, and described drag An optical fiber sensing device 23 is installed on the cable 25, and the optical fiber sensing device 23 includes a housing 2, an optical fiber bending sensing unit 6 and a top cover 3 arranged on the housing 2, and the housing 2 is provided with an opening And the moving bar 10 that is slidingly matched with the opening, one end of the moving bar 10 is connected with the slide plate 12 located in the housing 2, and the other end of the moving bar 10 is located outside the housing 2; A pull ring 8, the moving rod 10 is provided with a pull eye 7, the pull ring 8 and the pull eye 7 are connected to a pull cable 25, and the pull cable 25 is connected to a column 22; the optical fiber bendin...

Embodiment 2

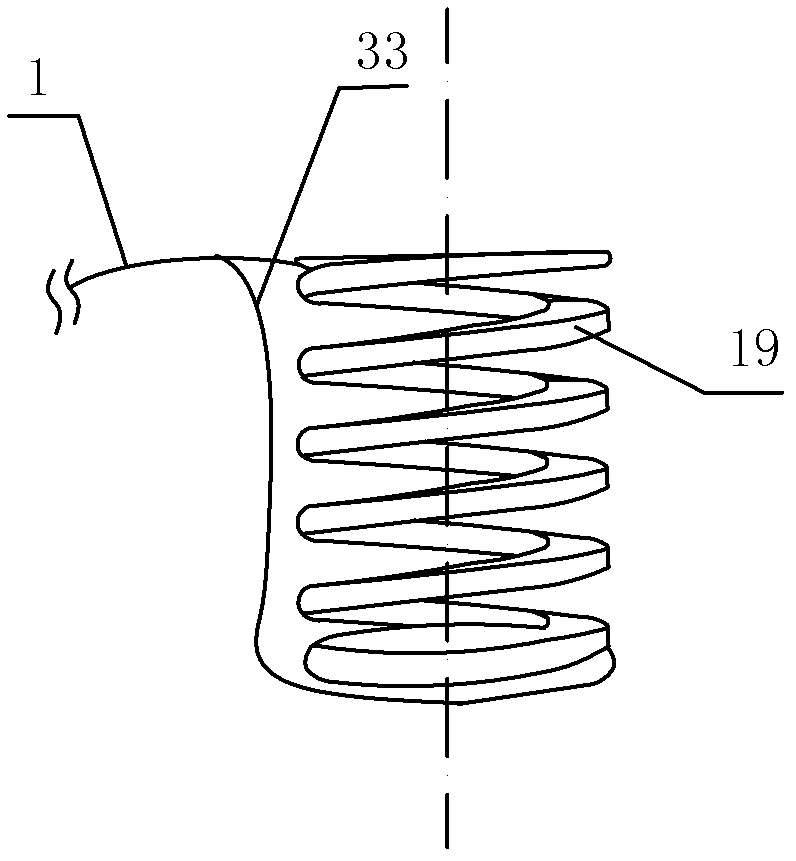

[0050] like Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the curved support is a spring 38, and a plurality of deformed teeth 4-1 and a plurality of deformed teeth 2 4-2 are correspondingly arranged in two adjacent turns in the spring 38 Between the spring wires, the first deformed tooth 4-1 and the second deformed tooth 4-2 are alternately arranged. In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

Embodiment 3

[0052] like Figure 6 and 7 As shown, the difference between this embodiment and Embodiment 1 is that the curved bracket is a corrugated tube 40, and the first deformed tooth 4-1 and the second deformed tooth 4-2 are arranged on the wall 42 of the corrugated tube 40 to be concave. On the opposite two sides of the place, and the first deformed tooth 4-1 and the second deformed tooth 4-2 are arranged alternately. In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com