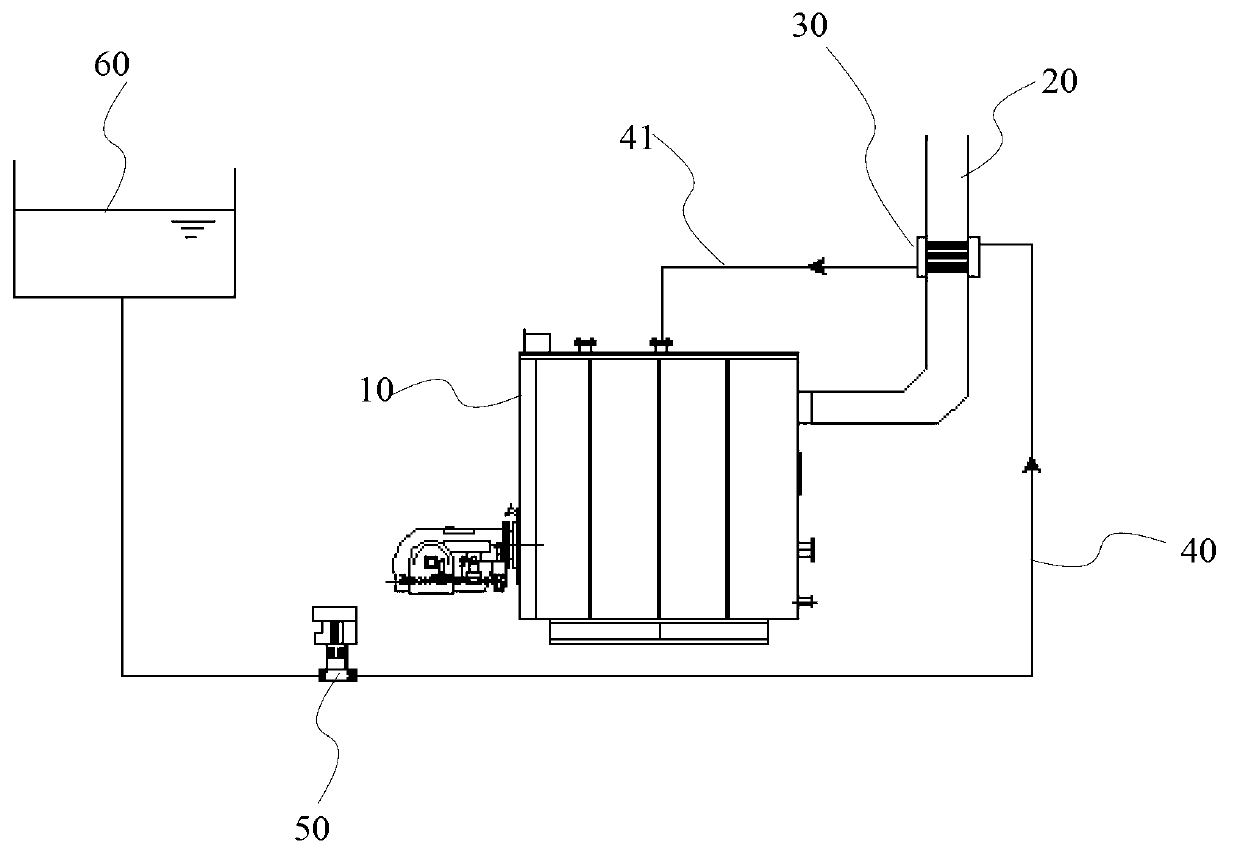

Boiler system with U-shaped flue and boiler water charging system

A flue, U-shaped technology, applied in the boiler system and boiler water supply system, can solve the problems of condensate recovery, flue corrosion, insufficient heat exchange, etc., and achieve the effects of reducing emissions, saving water resources, and reducing concentrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

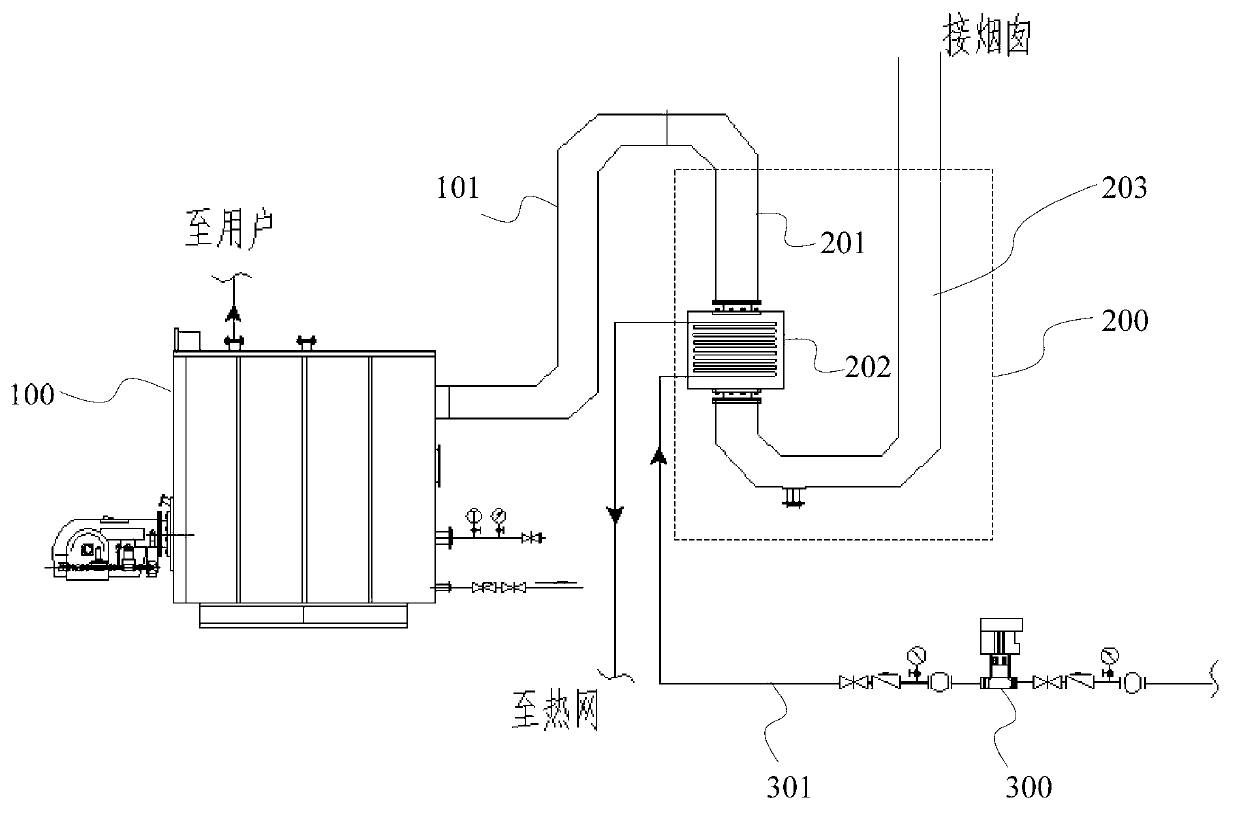

[0029] Such as figure 2 As shown, the boiler system with a U-shaped flue in this embodiment includes: a boiler body 100, a boiler flue 101 and a U-shaped flue device 200, and the U-shaped flue device 200 is connected to the boiler body 100 through the boiler flue 101. connect.

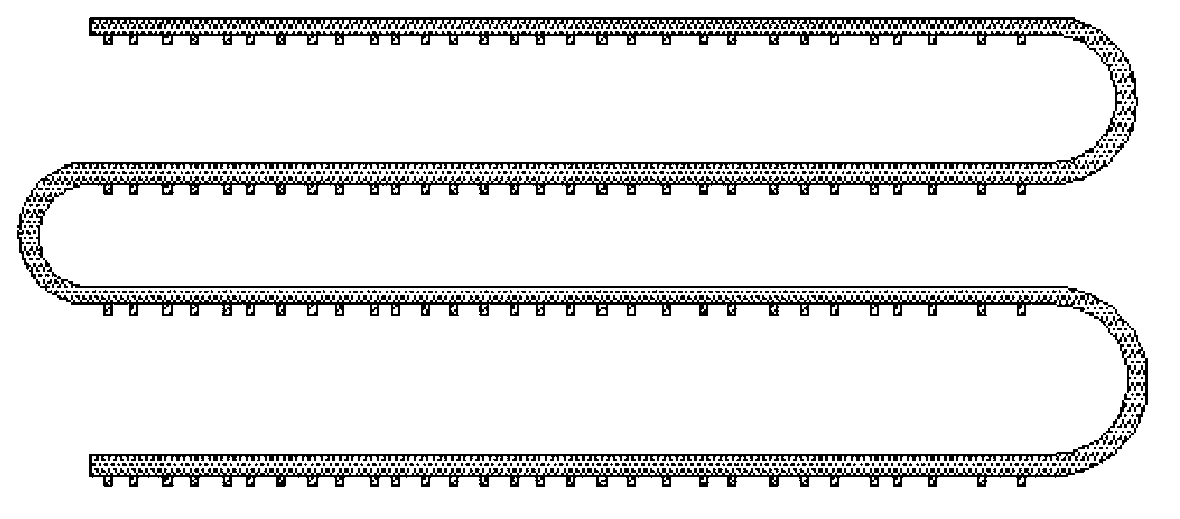

[0030] The U-shaped flue device 200 includes: a front vertical flue 201, which is airtightly connected with the boiler flue, and is used to make the flue gas discharged from the boiler flow from top to bottom in the front vertical flue; a heat exchanger 202, which is vertically connected to the front end. The straight flue 201 is airtightly connected, and is used to make the smoke discharged from the front vertical flue 201 flow through the water pipe of the heat exchanger 202 from top to bottom; the rear end "J" shaped flue 203 is airtightly connected with the heat exchanger 202, The smoke exhausted by the heat exchanger 202 flows from bottom to top in the rear end "J" shaped flue 203 and is dischar...

Embodiment 2

[0034] Such as Figure 4 As shown, the boiler system with a U-shaped flue in this embodiment includes: a boiler body 100, a boiler flue 101, a U-shaped flue device 200, and a condensate tank 210. The U-shaped flue device 200 passes through the boiler flue 101 and The boiler body 100 is connected.

[0035] The U-shaped flue device 200 includes: a front vertical flue 201, which is airtightly connected with the boiler flue, and is used to make the flue gas discharged from the boiler flow from top to bottom in the front vertical flue; a heat exchanger 202, which is vertically connected to the front end. The straight flue 201 is airtightly connected, and is used to make the smoke discharged from the front vertical flue 201 flow through the water pipe of the heat exchanger 202 from top to bottom; the rear end "J" shaped flue 203 is airtightly connected with the heat exchanger 202, The smoke exhausted by the heat exchanger 202 flows from bottom to top in the rear end "J" shaped flue...

Embodiment 3

[0046] The U-shaped flue boiler of this invention can not only be directly connected to the heat exchanger to recover primary waste heat, but also can be connected to a heat pump to perform deep flue gas waste heat recovery.

[0047] Take the winter heating of a residential area as an example: the boiler provides heating and water supply for users, and the heat pump system is connected to the boiler heat exchanger to heat the return water for secondary heating.

[0048] Such as Figure 5 As shown, the boiler system with U-shaped flue for district heating includes: boiler body, boiler flue and U-shaped flue device, condensate tank and heat pump, and the U-shaped flue device passes through the boiler flue and the boiler body The U-shaped flue device includes: the front-end vertical flue, which is airtightly connected with the boiler flue, and is used to make the flue gas discharged from the boiler flow from top to bottom in the front-end vertical flue; the heat exchanger, and T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com