Tube-sheet core device for flat-plate solar collectors

A flat-panel solar and tube-sheet technology, applied in solar thermal devices, solar thermal power generation, heating devices, etc., can solve the problem of reducing the solar energy absorption capacity of the flat heat absorbing plate, the damage to the solar selective absorption film layer, and the energy difference per unit area. and other problems, to achieve the effect of improving the utilization rate of heat exchange area, improving heat conduction efficiency, and large heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] see figure 1 , 2 , 3, 4, and 5 show preferred embodiments of the present invention.

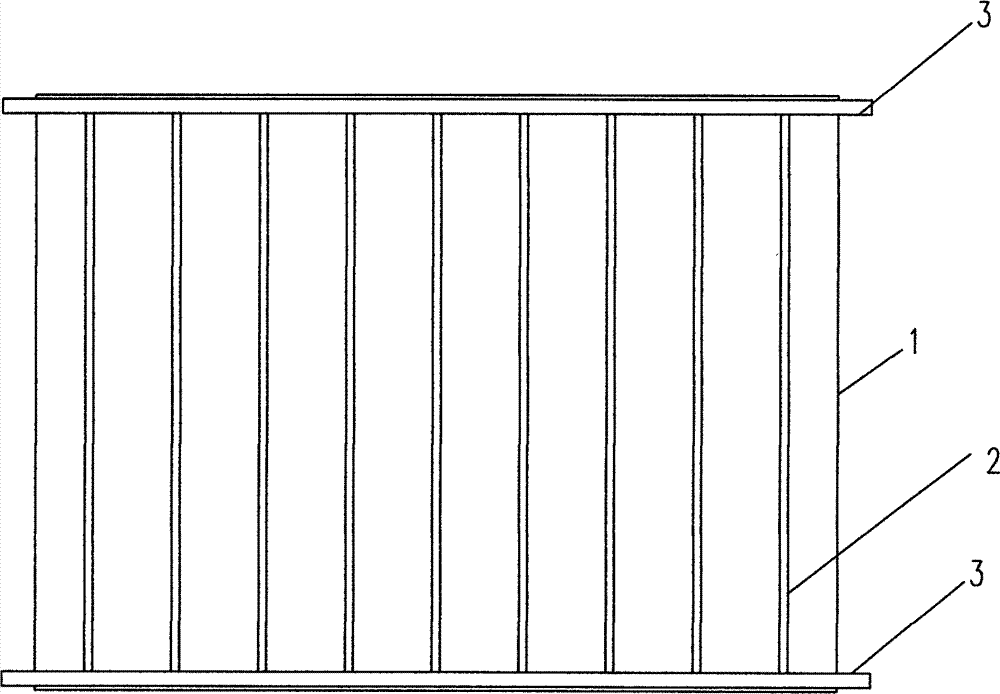

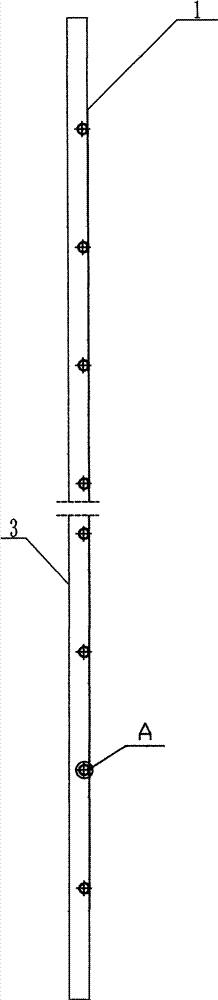

[0024] The tube-sheet type plate core device of the flat-panel solar collector includes two upper and lower diversion headers 3, a plurality of heat-absorbing row pipes 2 and a flat-plate heat-absorbing plate 1, and the diversion headers 3 arranged in parallel are separated from each other by a certain distance. One end of one of the diversion headers is connected to a cold water source, and the other diversion header can deliver hot water. A plurality of heat-absorbing exhaust pipes 2 parallel to each other are located between the above-mentioned diversion headers 3, and each absorbs heat Both ends of the row pipe are connected with the diversion header 3, thus forming a grid-shaped pipeline flow channel layout, such as figure 1 shown.

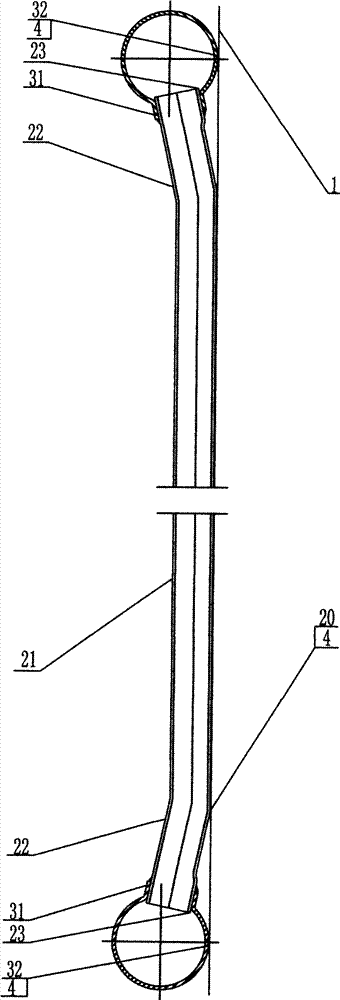

[0025] The two diversion headers 3 are circular tubes, and are evenly spaced with a plurality of receiving rings 31 for nesting the heat-absorbing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com